The manifold absolute pressure sensor, commonly known as the MAP sensor, is a key component of your 1994-1995 2.5L SOHC Dodge Dakota's engine management system.

So when this bad boy fails, your Dakota's engine performance is going to suffer big-time. Thankfully testing the MAP sensor can easily be done with just a multimeter.

As a matter of fact this multimeter test is so accurate, that you'll be able to confidently say the MAP sensor is bad or not with its test results.

Contents of this tutorial:

NOTE: The test for the 1996-1999 2.5L OHV Dodge Dakota can be found here: How To Test The MAP Sensor (1996-1999 2.5L OHV Dodge Dakota).

![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1994-1995 2.5L Dodge Dakota) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1994-1995 2.5L Dodge Dakota) (at: autotecnico-online.com).

Symptoms Of A Bad MAP Sensor

The fuel system on your 2.5L Dodge Dakota is a speed density system. In layman's terms, this means that the fuel injection system needs to know engine speed, manifold pressure, and intake air temperature to calculate the amount of air entering the engine.

With these three inputs, the fuel injection computer can now inject the correct amount of fuel for any given amount of air entering the engine.

Since the MAP sensor plays such a vital role in the fuel injection process of your 2.5L SOHC Dodge Dakota, when it fails, the engine is going to suffer some serious engine performance issues. You're going to see:

- The check engine light is lit with the following trouble code: Code 14: MAP Sensor Voltage.

- Engine is difficult to start.

- Rough engine idle.

- Black smoke coming out if the tail pipe when engine is running.

- Lack of power when accelerating the engine or vehicle down the road.

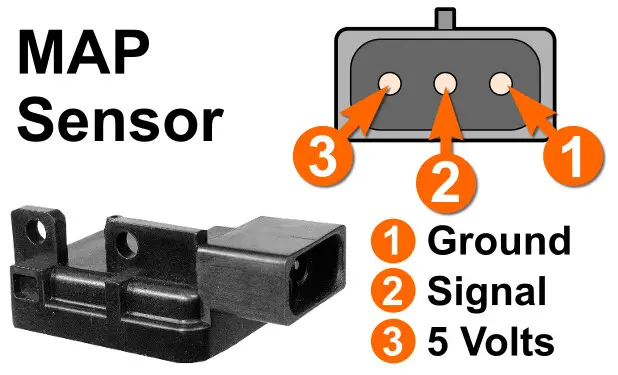

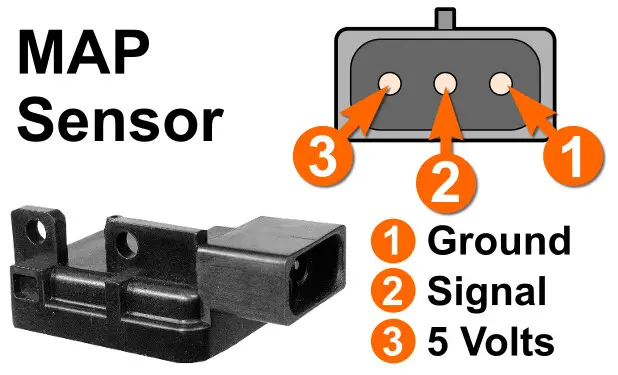

The MAP sensor is 3 wire type sensor. This means that it has a power wire, a Ground wire and a signal wire. The table below has a brief description of each:

| MAP Sensor Circuits 1994, 1995 2.5L Dodge Dakota | ||

|---|---|---|

| Terminal | Wire | Description |

| 1 | BLK/LT BLU | Ground |

| 2 | DK GRN/RED | MAP Signal |

| 3 | VIO/WHT | 5 Volts DC |

TEST 1: Testing The MAP Sensor Voltage Signal

The MAP sensor is connected to an intake manifold vacuum hose. As such, it reacts to changes in manifold vacuum pressure.

Now to be a bit more specific, when the engine is idling and manifold vacuum is low, the MAP sensor produces a high voltage signal.

When the engine is revved up, manifold vacuum is higher and the MAP sensor reacts by producing a low voltage signal.

In the majority of cases, when the MAP sensor fails, it will stay stuck producing a specific voltage value irregardless of the amount of vacuum and that it is being exposed to.

So very first thing that we are going to do is to test the MAP sensor while we apply vacuum with a vacuum pump. This is a very easy test and everything is explained in detail in the past steps below.

If you don't have a multimeter and need to buy one, check out my recommendations here: Buying A Digital Multimeter For Automotive Diagnostic Testing.

IMPORTANT: The MAP sensor needs to stay connected to its electrical connector for this test to work. You'll need to use a back-probe or a wire-piercing probe to measure the MAP signal voltage. To see what a wire-piercing probe looks like, go here: Wire Piercing Probe.

Let's get started:

- 1

Connect your vacuum pump to the MAP sensor's vacuum inlet port. Reconnect the MAP sensor to its connector if you disconnected it.

- 2

Set your multimeter's selector to Volts DC mode and with the red test lead, probe the DK GRN/RED wire of the MAP sensor's connector.

Remember, the MAP sensor must remain connected to its 3 wire connector. - 3

Ground the black multimeter test lead directly on the battery negative (-) terminal.

- 4

When everything is ready, turn the Key on but don't start the engine. This will power up the MAP sensor and you should see a reading of 4.7 Volts DC on your multimeter.

Now, apply vacuum to the MAP sensor with the vacuum pump (or your mouth). The voltage signal value should decrease.

Release the vacuum. Once released, your multimeter should show the original voltage value.

Repeat this test step several times making sure that each time the voltage decreases/increases as you apply/release vacuum.

Let's find out what your test results mean:

CASE 1: The MAP voltage signal decreased and increased as you applied and released vacuum. This is the correct and expected test result and lets you know that the MAP sensor on your 2.5L SOHC Dodge Dakota is not defective.

This test result also let you know that the MAP sensor is getting power and Ground from the fuel injection computer.

CASE 2: The MAP voltage signal DID NOT increase (and/or decrease) as you applied and released vacuum. In most cases, this test result is enough to confirm that the MAP sensor is defective and that it needs to be replaced.

But to be sure that the MAP sensor is defective, we need to make sure that it's getting power and Ground. For these two tests go to: TEST 2: Verifying MAP Sensor Has 5 Volts and Ground.

CASE 3: The multimeter DID NOT register any voltage. In most cases, this test result is enough to confirm that the MAP sensor is defective and that it needs to be replaced.

But to be sure that the MAP sensor is defective, we need to make sure that it's getting power and Ground. For these two tests go to: TEST 2: Verifying MAP Sensor Has 5 Volts and Ground.