This tutorial will help you diagnose a faulty ignition coil pack, faulty ICM or faulty crankshaft position (CKP) sensor on your 2.3L Ford Ranger (Ford Mustang, Mazda B2300) without removing it from the vehicle (on-car test).

Specifically, I'll help you diagnose two of the most common problems with this type of ICM configuration:

- An engine no-start problem due to a no-spark condition either because the:

- Crankshaft position sensor has failed.

- OR

- The ignition control module has failed.

- Misfire due to a bad ignition coil pack or a bad ignition control module.

Since the ICM is not cheap and replacing the CKP sensor is labor intensive (you'll have to remove the timing belt), testing the ICM and CKP sensor on your 2.3L Ford Ranger (Ford Mustang, Mazda B2300) is a must to make sure they're bad!

Contents of this tutorial:

- What Tools Do I Need To Test The Ignition Control Module Or The CKP sensor?

- Ignition Module Circuit Descriptions.

- Where To Buy The Ignition Module And Save.

- A Brief Description Of The Waste Spark Ignition System.

- How The Ignition Control Module Works.

- Start Diagnostic Here.

- TEST 1: Testing For Spark (Engine Does Not Start).

- TEST 2: Testing For Spark (Engine Starts).

- TEST 3: Making Sure The ICM Is Getting 12 Volts.

- TEST 4: Making Sure The ICM And CKP Sensor Are Getting Ground.

- TEST 5: Checking For Spark Directly On The 1/4 Ignition Coil Towers (Exhaust Side).

- TEST 6: Checking For Spark Directly On The 2/3 Ignition Coil Towers (Exhaust Side).

- TEST 7: Checking For Spark Directly On The 1/4 Ignition Coil Towers (Intake Side).

- TEST 8: Checking For Spark Directly On The 2/3 Ignition Coil Towers (Intake Side).

- TEST 9: Testing The CKP Signal With A Multimeter.

- TEST 10 Testing The CID Crankshaft Position Sensor Signal.

- TEST 11: Cylinders 1 And 4 Activation Signal (Exhaust Side).

- TEST 12: Cylinders 2 And 3 Activation Signal (Exhaust Side).

- TEST 13: Cylinders 1 And 4 Activation Signal (Intake Side).

- TEST 14: Cylinders 2 And 3 Activation Signal (Intake Side).

- TEST 15: Checking For Spark Directly On The Ignition Coil Tower.

![]() You can find this tutorial in Spanish here: Cómo Probar El Módulo De Encendido Y El Sensor del Cigüeñal (2.3L Ford) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Módulo De Encendido Y El Sensor del Cigüeñal (2.3L Ford) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 2.3L Ford Mustang: 1991, 1992, 1993.

- 2.3L Ford Ranger: 1989, 1990, 1991, 1992, 1993, 1994.

- 2.3L Mazda B2300: 1994.

For your cross reference information, the ignition control module test that this article covers are:

- AutoZone part #:

- Duralast F138

- O'Reilly Auto Parts part #:

- BWD CBE42

- Motorcraft DY959

- AC Delco F1929A

- Others:

- STANDARD MOTOR PRODUCTS Part # LX230T

- STANDARD MOTOR PRODUCTS Part # LX230

- Airtex Part # 6H1091

- WELLS Part # F138

What Tools Do I Need To Test The Ignition Control Module Or The CKP sensor?

Let me tell you right away that the only thing you don't need is a scan tool. You need a few basic things and these are:

- Multimeter.

- A digital or analog multimeter will work.

- If you need to buy one or are looking to upgrade, check out my recommendations here: Buying A Digital Multimeter For Automotive Diagnostic Testing.

- Wire Piercing Probe.

- This tool is a time saver of the first order. To see what this tool looks like, click here: Wire Piercing Probe.

You'll also need basic hand tools to remove the ignition module (if your test results confirm it's defective) such as a ratchet wrench, sockets, etc.

Ignition Module Circuit Descriptions

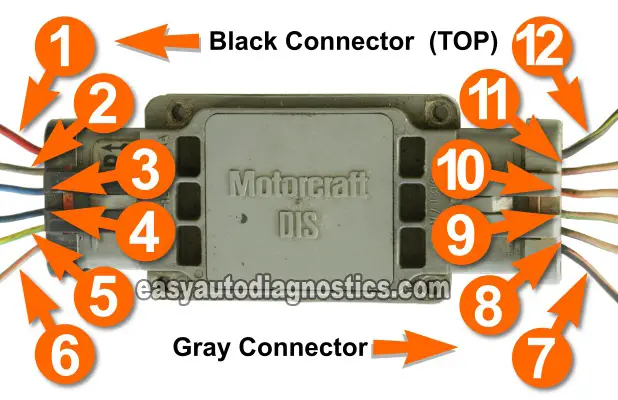

The ignition control module has two connectors. If you look down at the ignition module (with the ignition module still bolted to the intake manifold) you'll notice that the ignition control module has a top and bottom connector.

See the pinout tables below for a brief description of each wire's role.

NOTE: Although I have included the color of the wires in the tables below, there is a good chance these colors will not match those on your particular 2.3L Ford Ranger (Ford Mustang, Mazda B2300). This is nothing to worry about as the job description of the wires will not change.

Wiring Diagram: The following wiring diagram may be of help: 1992-1994 2.3L Ford Ranger Ignition System Wiring Diagram.

| Top ICM Connector Pin outs | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | Red w/ light green stripe (RED/LT GRN) * | Ignition Power (Hot in Start/Run) |

| 2 | Gray (GRY) * | Cylinder Identification (CID) |

| 3 | Gray w/ orange stripe (GRY/ORG) * | PIP (PCM Module Signal) |

| 4 | Dark blue (DK BLU) * | PIP (Crank Sensor Signal) |

| 5 | Pink (PNK) * | SPOUT Signal |

| 6 | Dark blue w/ yellow stripe (DK BLU/YEL) * | Dual Plug Inhibit (DPI) Input |

* Your specific Ford vehicle may have different colors.

| Bottom ICM Connector Pin out | ||

|---|---|---|

| Pin | Wire Color | Description |

| 7 | Orange w/ red stripe (ORG/RED) * | Ignition Ground |

| 8 | Tan w/ light blue stripe (TAN/LT BLU) * | Coil 3 (Spark Plugs #1 and #4 Left Side Engine) |

| 9 | Tan w/ light green stripe (TAN/LT GRN) * | Coil 4 (Spark Plugs #2 and #3 Left Side of Engine) |

| 10 | Tan w/ orange stripe (TAN/ORG) * | Coil 2 (Spark Plugs #2 and #3 Right Side of Engine) |

| 11 | Tan w/ white stripe (TAN/WHT) * | Coil 1 (Spark Plugs #1 and #4 Right Side of Engine) |

| 12 | Tan w/ yellow stripe (TAN/YEL) * | Ignition Diagnostic Monitor (IDM) |

* Your specific Ford vehicle may have different colors.

Where To Buy The Ignition Module And Save

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

A Brief Description Of The Waste Spark Ignition System

A coil pack with 2 towers not producing spark to two paired cylinders is the most common failure mode in this type of Ford ignition control module (ICM).

To better understand this phenomenon, you and I need to know that the 1989-1994 2.3L Ford Ranger (Ford Mustang, Mazda B2300) uses a Waste Spark ignition system.

In this type of ignition system, two ignition coil pack towers fire spark to two spark plugs simultaneously. Here are the details:

- Each coil pack feeds 4 spark plugs.

- Ignition coil towers for cylinders #1 and #4 fire spark at the exact same time.

- Ignition coil towers for cylinders #2 and #3 fire spark at the exact same time.

- The cylinders that receive spark simultaneously are referred to as 'paired' cylinders.

- Each coil pack fires spark to spark plugs on one side of the engine.

- Spark plugs on the side of the exhaust manifold are called: exhaust side spark plugs.

- Spark plugs on the side of the intake manifold are called: intake side spark plugs.

- Each coil pack is made up of 2 individual ignition coils.

- Each coil has 2 towers.

- When the individual ignition coil (within the coil pack) fires, this spark is sent out on both towers.

- Each coil pack has 3 wires

- The middle wire is the one that supplies 12 Volts to both individual ignition coils within the coil pack.

- The other 2 wires are the ones that supply an activation signal (switching signal) to each individual ignition coil.

So if you have 2 towers from the same coil pack not firing spark, it's usually due to one of two reasons:

- The coil pack is bad.

- The ignition control module (ICM) has fried internally and is not activating them specific ignition coil within the coil pack (although it activates the others).

An ignition control module (ICM) not activating one of the two individual ignition coils in the coil pack is the most common problem of the two and is not difficult to confirm with a few simple tests.

How The Ignition Control Module Works

The ignition control module has the task of activating the two ignition coil packs that feed the 8 spark plugs that the 2.3L 4-cylinder engine is equipped with.

Now I'll not go into the smallest technical detail of how everything works in this ignition system. Just the basics you and I need to get to the bottom of the problem. In a nutshell, here's what happens when you turn on the ignition key and start the engine:

- The CKP sensor is fed with 12 Volts and Ground.

- The CKP sensor is a Hall Effect sensor.

- The rotation of the crankshaft causes the crankshaft position sensor to begin generating two separate output signals.

- One signal is called the CKP signal. The CKP signal is only sent to the ICM.

- The other crankshaft position signal is called the CID (Cylinder Identification) signal.

- The CID signal helps the ignition control module synchronize the ignition coil packs so they fire in the correct firing order.

- Both the ICM and PCM receive the CID signal.

- The ignition control module now starts activating the ignition coil packs.

- During engine cranking, only the spark plugs on the right side (exhaust manifold side of the engine) are fired.

- Once the engine starts, the PCM now commands the ICM to fire both ignition coil packs via the DPI (Dual Plug Inhibit) circuit (circuit 6 of the top ICM connector).

- Each coil pack feeds spark to 4 spark plugs on both sides of the engine.

- Spark plugs on the intake manifold side of the engine are referred to as: intake side spark plugs or left side spark plugs.

- Spark plugs on the exhaust manifold side of the engine are referred to as: exhaust side spark plugs or right side spark plugs

If you're reading this tutorial, it's because you have a problem and this stinks, but the really cool thing is you can test the ignition control module and CKP sensor without having to replace them first and I'll show you how.

Let's turn the page and get testing.