I remember when the Quad 4 engine first came out and thinking what a pain in the ass diagnosing and repairing it would be. And as time went on, I found out just how right that first impression was.

Well, in this article, I've made diagnosing the ignition control module (ICM) and the crankshaft position sensor (7X CKP sensor) as easy and as pain free as possible. With this test, you'll be able to pinpoint the problem to the ignition control module (ICM) or the crankshaft position sensor (7X CKP sensor).

Before starting the tests you must first check and verify that there's NO SPARK present at any of the coil towers causing the car NOT TO START. Why? Because this article only shows you how to test the ignition control module and CKP sensor but not the ignition coils. If your car cranks and starts, but runs with a misfire and you need to test the ignition coils, the following tutorials will help:

For the ignition control module tests for the 2.2L GM engine, go here:

For more info on the basics of troubleshooting a no-start condition, I recommend the following tutorial:

- How To Troubleshoot A No Start (GM 2.3L, 2.4L Quad 4) (at: troubleshootmyvehicle.com).

Contents of this tutorial:

- Basic Operating Theory.

- Where Do We Start?

- What Tools Do I Need?

- Test Info: The Circuit Descriptions.

- TEST 1: Checking For 12 Volts.

- TEST 2: Checking The Ground Circuit.

- TEST 3: Testing The 7X CKP Signal.

- Symptoms Of A Bad 7X CKP Sensor.

- TEST 4: Testing The 7X Reference Signal.

- Symptoms Of A Missing 7X REFERENCE Signal.

- TEST 5: 1-4 & 2-3 Coil Control Signal.

- TEST 6: Crankshaft Position Sensor Resistance.

![]() You can find this tutorial in Spanish here: Cómo Probar El Módulo De Encendido Y Sensor Del Cigüeñal (GM 2.4L) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Módulo De Encendido Y Sensor Del Cigüeñal (GM 2.4L) (at: autotecnico-online.com).

Basic Operating Theory

Here is a little background information to help you diagnose this no-spark condition. In a nutshell, when the system is working properly, at crank-up and at all engine speeds, the ECM (Fuel Injection Computer) controls both ignition coils thru' the ignition control module (ICM). How?

- As the engine cranks and starts, the ignition control module (ICM) receives the crankshaft position (7X CKP) sensor signal.

- This crankshaft position sensor signal is an AC voltage signal that the ignition module now transforms into a digital signal and sends it to the fuel injection computer.

- The fuel injection computer, upon receiving this modified crankshaft position sensor signal (which GM calls the 7X REFERENCE Signal), creates two separate Ignition Coil Control Signals that it sends back to the ignition control module.

- These Ignition Coil Control Signals are the ones that the ignition module uses to start sparking the two ignition coils that are connected to it.

- One Ignition Control Signal is for the ignition coil that fires cylinders 1 and 4 and the other for the one that fires cylinders 2 and 3.

- Also, with this 7X REFERENCE signal, the fuel injection computer knows when to start activating the fuel injectors.

OK, the only thing you have to remember from all of this is the difference between the 7X CKP signal and the 7X REFERENCE signal. There'll be a quiz at the end of the tutorial.

Where Do We Start?

We'll first check for the basics like battery voltage and engine Ground to the ignition control module. Then we'll test the 7X crankshaft position sensor signals, the 7X REFERENCE signal and the ignition coil control signals (from the ECM to the module) in action and from the results you get you'll be able to pinpoint the problem to the ignition control module or the crankshaft position sensor or completely eliminate these as the cause of the no-start condition.

IMPORTANT: All of the tests are ON-CAR TESTS, do not remove the coil/module assembly from the vehicle (all of the figures show the coil module assembly off of the car but this is just for illustration purposes only). And lastly, this test only tests for a no-start condition.

What Tools Do I Need?

No expensive diagnostic equipment is needed. You don't even need a scan tool. In case you're one of the privileged few who owns an oscilloscope, I have included photos of what the waveforms should look like. Whether you use a multimeter or an oscilloscope, you'll be able to successfully diagnose this no-start condition! So, read on my friend.

- A digital multimeter that can read Hertz (Hz) Frequency.

- This multimeter, that can read Hertz Frequency, is a must have or you won't be able to accomplish some of these tests (don't have a digital multimeter that can read Hertz frequency? See my recommendations here: Buying A Digital Multimeter For Automotive Diagnostic Testing).

- A helper

- To help you crank the engine.

- A repair manual.

- For any info that's not covered in this article.

Test Info: The Circuit Descriptions

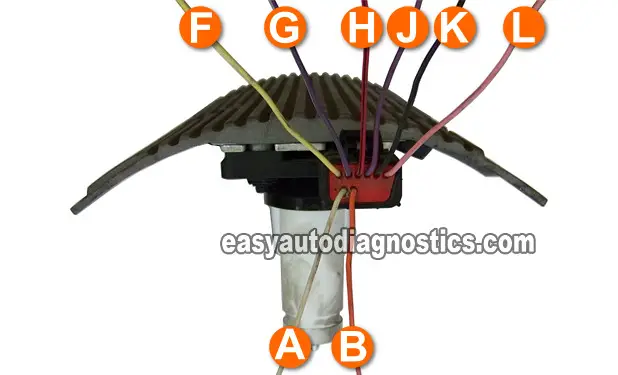

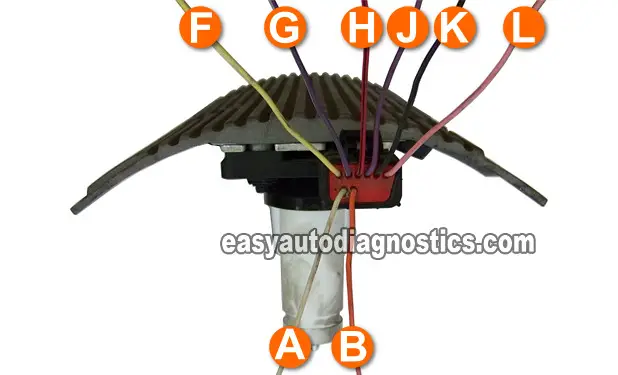

Here are brief descriptions of the circuits that we'll be testing. The ignition control module harness connector will have the same letters on it.

- A- WHITE wire. 1-4 Ignition Coil Control Signal (comes from the ECM).

- B- ORANGE wire. 2-3 Ignition Coil Control Signal (comes from the ECM).

- C- Empty. No circuit exists.

- D- Empty. No circuit exists.

- E- Empty. No circuit exists.

- F- YELLOW wire. Crankshaft position sensor circuit.

- G- PURPLE with WHITE stripe wire. 7X Reference signal (goes to the ECM).

- H- RED with BLACK stripe wire. Ground circuit for ECM.

- J- PURPLE wire. Crankshaft position sensor circuit.

- K- BLACK wire. Engine Ground (for the module).

- L- PINK wire. 12 Volts with ignition ON.

Now, don't worry, it's lots of wires but you'll see just how easy it is to test this module. All right, let's get started!

TEST 1: Checking For 12 Volts

We'll begin by checking the basics first and this means checking that the Quad 4 ignition control module (ICM) is receiving 12 Volts.

I recommend using a wire piercing probe to accomplish all of the tests in this article. (Wire Piercing Probe). Whatever method you use, the key here is to be careful.

One last thing, some of these tests require the test to be done while cranking the engine, so please be careful, use common sense and take all safety precautions.

Alright, this is what you need to do:

- 1

Put the multimeter in Volts DC mode (or you can use a test light).

- 2

It's not necessary to disconnect the ignition control module. You'll probe the L circuit of the ignition control module (ICM) connector.

- 3

With the red multimeter test lead and a suitable tool, probe the PINK wire of the ICM's harness connector.

- 4

With the black multimeter test lead probe the battery negative (-) terminal.

- 5

Turn key on with the engine off. You should see 12 Volts on the multimeter. Do you have 12 Volts?

Let's take a look at your test results:

CASE 1: Your multimeter confirmed 12 Volts. This is good and the expected test result which tells you that the ignition control module (ICM) is getting power.

Your next step is to make sure that the ICM is getting Ground. For this test go to: TEST 2: Checking The Ground Circuit.

CASE 2: Your multimeter DID NOT confirm 12 Volts. Recheck your multimeter connections and repeat the voltage test.

If your multimeter still does not register 12 Volts when you turn the key to the ON position, then you have confirmed that the ignition control module is NOT being fed power (12 Volts).

Although it's beyond the scope of this tutorial, you must find out why you're missing this voltage. Without this voltage the ignition control module will not work.