When the GM 7-pin HEI ignition control module (ICM) fails, your 2.8L V6 Chevy S10 pickup (GMC S15 pickup, GMC Sonoma) will crank but not start.

Don't worry! Testing the ICM is easier than you think and can be done without removing it from the vehicle and doesn't require any expensive diagnostic equipment.

With a few basic tools and a simple process of elimination, you can easily determine if the module is good or bad. In this tutorial, I'll show you how step by step.

IMPORTANT: Before testing the ignition control module, it's important to check the ignition coil first. If you find that the ignition coil is producing spark, you can conclude that the ignition control module is working properly. You can find the ignition coil test here: How To Test The Ignition Coil -No Start Tests (1988-1993 2.8L Chevrolet S10 Pickup, GMC S15 Pickup, GMC Sonoma).

Contents of this tutorial at a glance:

- Symptoms Of A Bad Ignition Control Module.

- What Tools Do I Need To Test The ICM?

- Ignition Control Module Circuits.

- Where To Buy The Ignition Control Module And Save.

- TEST 1: Making Sure The ICM Is Getting Power.

- TEST 2: Verifying The Ignition Coil Activation Signal.

- TEST 3: Verifying The Pickup Coil's Signal.

- More 2.8L Chevy S10 Pickup, GMC S15 Pickup, And GMC Sonoma Tutorials.

![]() You can find this tutorial in Spanish here: Cómo Probar El Módulo De Encendio (2.8L V6 GM) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Módulo De Encendio (2.8L V6 GM) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 2.8L Chevrolet S10 Pickup: 1988, 1989, 1990, 1991, 1992, 1993.

- 2.8L GMC S15 Pickup: 1988, 1989, 1990.

- 2.8L GMC Sonoma: 1991, 1992, 1993.

This tutorial also applies to the 2.8L Chevy S10 Blazer, 2.8L GMC S15 Jimmy. See the 'Applies To' box on the left column (desktop) or at the bottom of the page (mobile device) for more info.

You can find the ignition system circuit diagram here: 1991-1993 2.8L Chevy S10 Ignition System Circuit Diagram.

If you need to test the 8-pin ignition module, the following tutorial will help: How To Test The GM Distributor Mounted Ignition Module.

The following circuit wiring diagram may be of help: 1991-1993 2.8L Chevy S10 Ignition System Circuit Diagram.

Symptoms Of A Bad Ignition Control Module

To make this short, sweet, and to the point; the engine is not going to start due to a lack of spark and or fuel injection when the ignition control module (ICM) fails on your 2.8L v6 engine.

This is due to the fact that the ignition control module is in charge of:

- Activating the ignition coil to spark.

- Sending the fuel injection computer the crankshaft position to start injecting fuel (pulsing the fuel injectors).

This means that if your 2.8L equipped S10 (GMC S15) has spark and you can see the two throttle body fuel injectors injecting fuel, then the ignition control module (ICM) is OK and not defective.

What Tools Do I Need To Test The ICM?

As I mentioned at the beginning of this tutorial, you don't need an expensive automotive diagnostic test equipment to test the ignition control module (ICM). As a matter fact, you don't even have to remove it from the distributor to test it.

These are the tools you'll need:

- Multimeter that can read Volts DC and Volts AC.

- 12 Volt test light.

As you can see, nothing that'll break the bank. Now, in case you don't have a multimeter or need to upgrade yours, take a look at my recommendation here: Buying A Digital Multimeter For Automotive Diagnostic Testing.

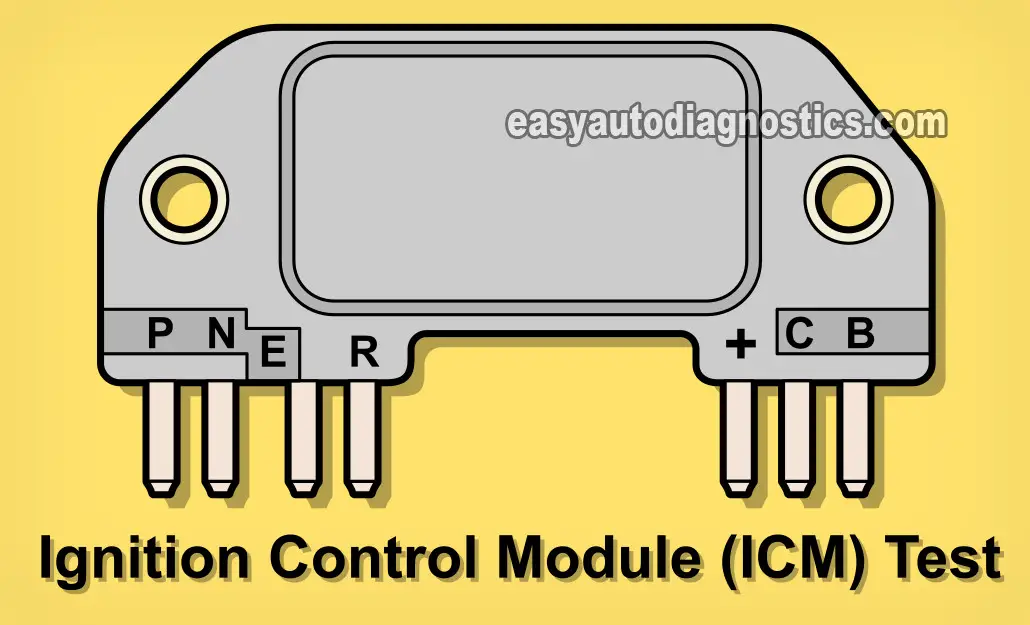

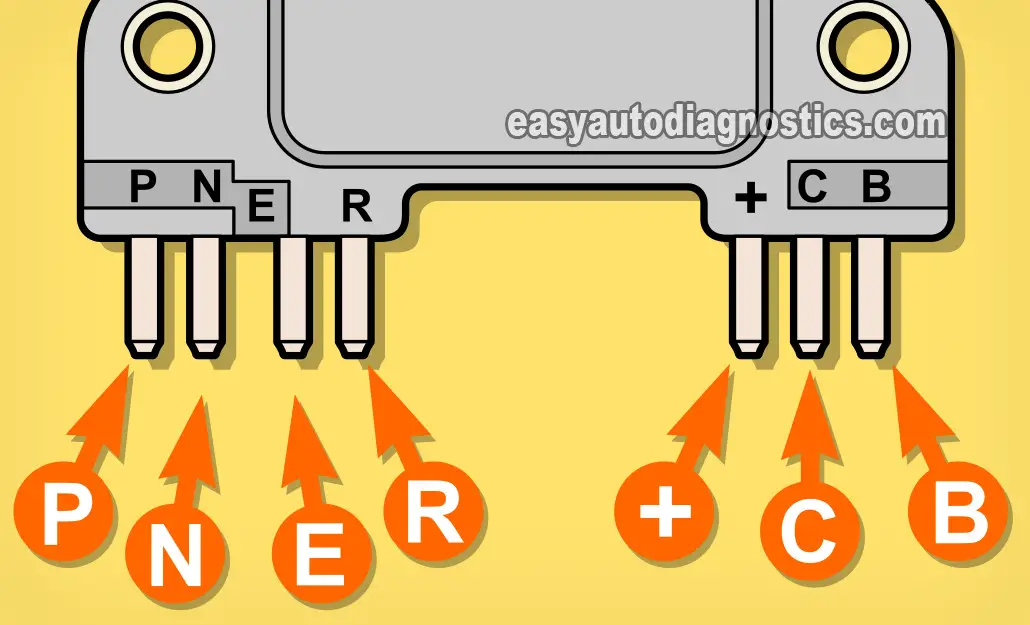

Ignition Control Module Circuits

As you can see, the ignition control module has quite a few pins. Each one of these has a specific job to do. In this section, I'm gonna' give you a very brief job description of each. This will give you an idea of what circuits we will be testing in the following pages of this tutorial.

| 4-PIN CONNECTOR | |

|---|---|

| Terminal | Description |

| P | Pickup Coil |

| N | Pick Coil |

| E | Ignition Control (IC) |

| R | Ignition Control (IC) Reference High |

| 3-PIN CONNECTOR | |

|---|---|

| Terminal | Description |

| + | 12 Volts |

| C | Ignition Coil Control Signal (ignition coil activation signal) |

| B | Ignition Control (IC) Bypass |

On the ignition module itself, the only two terminals that we're going to worry about are the pickup coil inputs. We'll be testing the pickup analog voltage AC signal in TEST 3: Verifying The Pickup Coil's Signal.

Where To Buy The Ignition Control Module And Save

When it comes to purchasing an ignition control module (ICM) for your vehicle, it's important to avoid the temptation to buy a cheap, no-name knockoff. While the initial savings in price may seem attractive, it's likely that the ICM will fail in just a few days, leaving you with the same problem and a lighter wallet.

Instead, purchase a well-known, reputable brand of ICM that can withstand the extreme heat the ICM is exposed to inside the distributor. To help you find a high-quality ICM, I've included links to some well-known automotive brands below:

- Delphi DS10068 Ignition Control Module (at: amazon.com)

- Standard Motor Products LX316T Ignition Control Module (at: amazon.com)

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

Not sure if the above ignition control module (ICM) fits your particular S10? Don't worry, once you click on the links and arrive on the site, they'll make sure it fits! If it doesn't, they'll find you the right one.

TEST 1: Making Sure The ICM Is Getting Power

The very first thing that we're going to do, is to make sure that the ignition control module (ICM) is getting power, which is in the form of 10 to 12 Volts.

These 12 Volts are supplied to the ignition control module through the pink (PNK) wire of the black ignition coil connector.

The test for the 12 Volts can be performed either at the distributor connector or at the black ignition coil connector, but it's more convenient and accessible to do at the black ignition coil connector.

In the test instructions below, the 12 Volts are checked at the pink (PNK) wire of the black ignition coil connector.

You can use a 12 Volt test light if you like to test for power, but for a more accurate test result I suggest that you use a multimeter. If you don't have a multimeter or need to upgrade yours, take a look at my recommendations here: Buying A Digital Multimeter For Automotive Diagnostic Testing.

IMPORTANT: Before testing the ignition control module, make sure that the engine is not starting due to a lack of spark. If the spark plug wires are sparking and fuel injectors are injecting fuel, then the ignition control module is functioning properly and is not the cause of the engine not starting.

OK, these are the test steps:

- 1

Locate the pink wire of the black ignition coil connector (see photo above). This is the wire that feeds power to the ignition control module.

Both ignition coil connectors (black and gray) must remain connected to the ignition coil.

The best way to test for the voltage inside the bank wire is using a back probe or a wire piercing probe. To see what a wire piercing probe looks like, go here: Wire Piercing Probe Review (Power Probe PWPPPPP01). - 2

Place your multimeter in Volts DC mode.

- 3

Connect the red multimeter test lead to the pink wire of the black ignition coil connector.

- 4

Connect the black multimeter test lead to the battery negative (-) post.

- 5

Turn the key to the ON position but don't crank or start the engine.

- 6

Your multimeter should report 10 to 12 Volts DC.

Alright, let's take a look at what your test results mean:

CASE 1: Your multimeter confirms that 10 to 12 Volts are present in the pink wire. This is the correct and expected test result.

Now that we have confirmed that the ignition module is getting power, the next step is to check that the ignition module is creating the ignition coil's activation signal. For this test go to: TEST 2: Verifying The Ignition Coil Activation Signal.

CASE 2: Your multimeter confirms that 10 to 12 Volts are MISSING in the pink wire. These missing 10 to 12 Volts are what is causing the ignition module to not activate the ignition coil.

Your next step is to find out why these 12 Volts are missing. Restoring this battery voltage will get the ignition module working again and the engine should start.

To further help you ignition control module troubleshooting efforts, you can find the ignition system circuit diagram here: 1991-1993 2.8L Chevy S10 Ignition System Circuit Diagram.