TEST 2: Making Sure The MAF Sensor Is Getting Ground

In this test section, we're gonna' make sure that the black (BLK wire of the MAF sensor harness connector is feeding the MAF sensor with Ground.

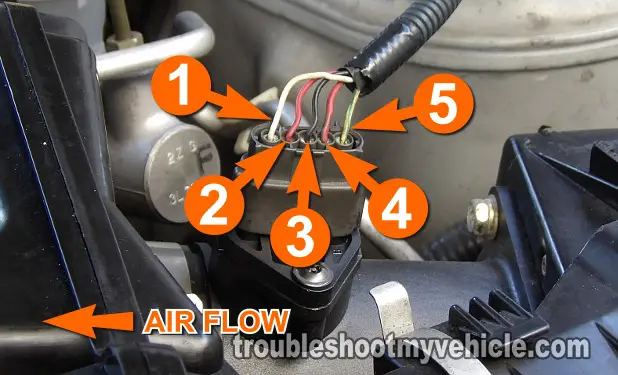

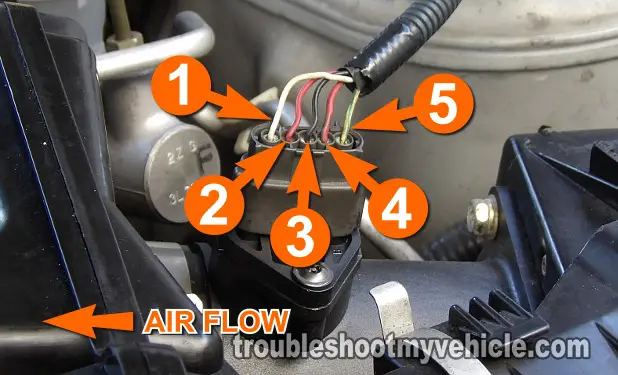

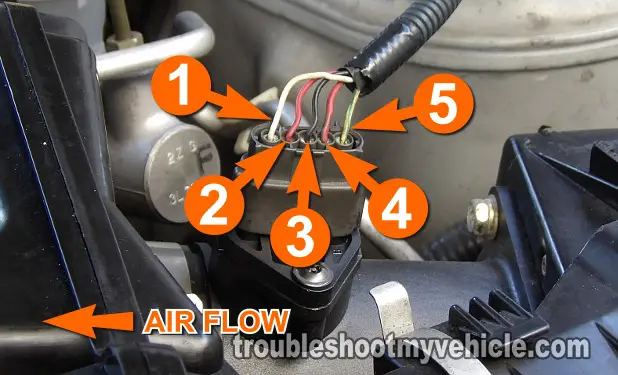

The BLK wire is labeled with the number 3 in the photo above.

IMPORTANT: Be careful not to short this wire to battery power or you'll fry your Maxima's fuel injection computer. The multimeter voltage test indicated below is a safe way to test this Ground circuit.

Alright, let's get started:

- 1

Turn key to the ON Position but don't crank or start the engine.

Place your trusty multimeter in Volts DC mode. - 2

Test the BLK wire identified with the number 3 in the photo above with the black multimeter test lead.

- 3

Connect red multimeter test lead to the battery positive (+) terminal.

- 4

Your multimeter should register 10 to 12 Volts if Ground is available in the BLK wire.

Let's take a look at what your test results mean:

CASE 1: Your multimeter registered 10 to 12 Volts. This result indicates that the Maxima's MAF sensor has a good Ground circuit. The next step is to test the MAF signal, go to: TEST 3: Testing The 5 V Reference Signal.

CASE 2: Your multimeter DID NOT register 10 to 12 Volts. Recheck all of your multimeter connections and try the test again. If still no voltage, then this result exonerates the Maxima's MAF sensor as the cause of the MAF code lighting up your check engine light (CEL) or MAF issue, since without this Ground, the MAF sensor will not produce a signal to the computer.

Finding and repairing the cause of this missing Ground will resolve the MAF sensor issue with your Nissan Maxima.

TEST 3: Testing The 5 V Reference Signal

So far you've made sure that the MAF sensor has battery power and Ground. The next step is to make sure it's getting a 5 Volt reference voltage signal from the fuel injection computer.

The wire that delivers these 5 Volts DC to the MAF sensor is the red (RED) wire of the MAF sensor harness connector.

These are the test steps:

- 1

Probe the red wire of the MAF sensor connector that is identified with the number 2 in the photo with the red multimeter test lead.

- 2

Connect the black multimeter test lead to the battery negative (-) terminal.

- 3

Place your multimeter in Volts DC mode and turn the key on (but don't crank or start the engine).

- 4

The multimeter should display 4.5 to 5 Volts DC.

Let's take a look at what your test results mean:

CASE 1: The multimeter registered 5 Volts. This test result tells you the circuit is OK and the computer is doing its job. The next step is to verify that the Maxima's mass air flow sensor is creating a MAF signal the computer can use. For this test go to: TEST 4: Testing The MAF Signal.

CASE 2: The multimeter DID NOT register 5 Volts. This test result means you must find the cause of these missing 5 Volts. Without this voltage the MAF sensor will not function.

TEST 4: Testing The MAF Signal

In this last test, we're gonna' test the MAF signal itself with a multimeter.

If the MAF sensor is functioning correctly, then it should produce a low voltage signal at engine idle that should increase as you rev the engine up.

If the MAF is fried, then the voltage signal will stay stuck in one value no matter how much you rev up the engine.

The wire that carries the MAF signal is the white (WHT) wire of the MAF electrical connector.

OK, let's get started:

- 1

Probe the white (WHT) wire that's identified with the number 1 in the photo with the red multimeter test lead.

- 2

Connect the black multimeter test lead to the battery negative (-) terminal.

- 3

Put the multimeter in Volts DC mode and crank and start the engine. If the engine is completely cold, let it warm up before the next step.

- 4

At engine idle, you should see about 1.2 Volts on your multimeter. Now, this reading may be stable (with only small fluctuations) or unstable with very large fluctuations. No matter what the instability in the reading, this will be your base voltage reading.

- 5

Manually accelerate the engine as you observe how the multimeter's voltage value increases. As a reference point, at around 2,500 RPMs you should see about 2.5 Volts.

The higher you accelerate the engine, the higher the voltage reading on your multimeter. - 6

Let the engine return to idle

You should see the voltage value on the multimeter return to the base voltage value you recorded in step 4. This voltage reading may not be the exact same but should be very close. - 7

Rev up/rev down the engine several times as you look for the corresponding increase/decrease in voltage.

- 8

If the MAF sensor is good, these readings will not spike up and down crazily or stay stuck in one value but will increase/decrease as you rev up/rev down the engine.

Let's take a look at what your test results mean:

CASE 1: The voltage reading increased and decreased as you were revving up/revving down the engine, then the Maxima's MAF sensor is working correctly.

Here's why: If the MAF sensor were faulty, your multimeter's reading would have stayed stuck at one value no matter how much you revved up the engine. Since the value went up as you revved up the engine, then you can consider the MAF sensor working correctly.

CASE 2: The voltage reading DID NOT increase and decrease as you were revving up/revving down the engine, then the mass air flow sensor on your Nissan Maxima is bad. Replace the MAF sensor.