Interpreting The Compression Test Results

Now that you've done the compression test, the next important thing is to interpret the test results. If you got 4 different compression values, let me tell you that this could be normal.

The engine cylinders, particularly in high-mileage engines, don't wear out exactly the same. But if the compression values vary too much, then you've got a problem that'll cause a misfire condition.

The rule of thumb is that the lowest compression value can not vary more than 15% of the highest value (that you got in TEST 1). If any value is lower by more than 15%, then that engine cylinder can be considered dead and is going to misfire.

How do you figure this out? You can find out by using my online low compression calculator here: Online Low Engine Compression Calculator or by calculating this 15% difference manually.

To understand how to figure out this 15% thing manually, on your 2.5L Dodge Dakota, let's say that I got the following compression values:

- Cylinder #1 175 PSI.

- Cylinder #2 165 PSI.

- Cylinder #3 160 PSI.

- Cylinder #4 140 PSI.

The next step is to do the following math:

- Multiply .15 (15%) by the highest value: 175 x 0.15. This gives us 26.25, but we'll round it out to 26.

- Next, we subtract 26 from 175: 175 - 26 = 144.

- So now we know that the lowest possible compression value is: 144 PSI.

This means that cylinder #4 (at 140 PSI) is the one causing the misfire because it's below the 144 PSI minimum.

Once we've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Compression Test.

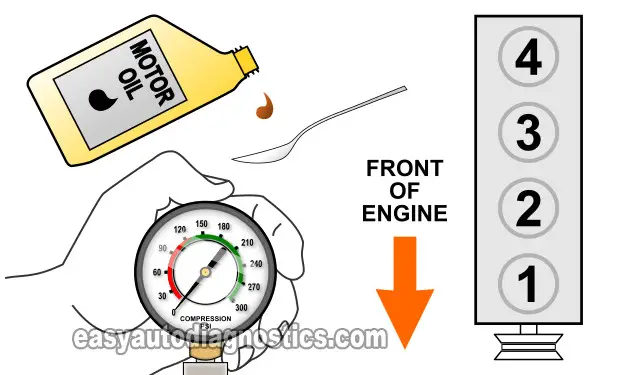

TEST 2: Wet Compression Test

There are usually two main causes of low compression (or zero) compression in a cylinder.

The first one is that the dead cylinder's piston rings are severely worn out. The other one is that the dead cylinder's head valves are severely worn-out or damaged.

In either case, we don't have to tear the engine apart to find out. We can find out by doing a wet compression test. This test simply involves adding about two spoonfuls of oil into the cylinder (with bad compression) and retesting it again.

OK, this is what you'll need to do:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest. I suggest using a small and long funnel so that the oil will reach the inside of the cylinder.

- 2

Once you've added the oil, install the compression gauge, and as before just hand tighten it.

- 3

Now, have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

As before, your job is to keep an eye on the gauge, and you'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder, or...

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

If you have another cylinder that needs to be tested, repeat steps 1 thru' 4 on it now.

Let's take a look at what your compression test results mean:

CASE 1: The compression value shot up for the low compression cylinder. Since the compression value shot up, you can conclude that low compression value you got in TEST 1 is due to extremely worn out piston rings.

The reason the compression value shot up is due to the fact that the motor oil you just added helped the piston rings to create a tighter seal. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: Your compression value DID NOT shoot up (stayed the same). Since the compression value did not shoot up, you can conclude that the bad compression value you got in TEST 1 is due to extremely worn-out or damaged cylinder head valves.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make two recommendations to you:

1) Which one to buy: The engine compression tester that I have always used is the Actron CP7827 Compression Tester Kit. My only complaint about this engine compression tester is that it does not come with a case to store it in.

2) Where to buy: You can buy an engine compression tester in any auto parts store in any neighborhood, in any city, but you'll be paying at least twice as much. Go to the above compression tester links, browse and compare, you'll see a big price difference!

If this info saved the day, buy me a beer!