This is a comprehensive tutorial on how to test the EGR valve that'll help you diagnose the EGR valve as good or bad in a step-by-step way.

The cool thing is that you don't need expensive or exotic diagnostic tools to perform any of the tests in this tutorial.

Contents of this tutorial:

- Symptoms Of A Bad EGR Valve.

- Important Testing Tips.

- What Tools Do I Need To Test The EGR Valve.

- TEST 1: Checking For Continuous Vacuum To EGR Valve.

- TEST 2: Applying Vacuum To The EGR Valve.

- TEST 3: Bench Testing The EGR Valve.

- TEST 4: Making Sure The EGR Valve Pintle Is Not Stuck Open.

- TEST 5: Checking For Blocked EGR Passages.

- How Can I Tell If I Have A Negative Or Positive Back Pressure EGR Valve?

- More 2.2L Beretta, Cavalier, Corsica, And Sunfire Diagnostic Tutorials.

![]() You can find this tutorial in Spanish here: Cómo Probar La Válvula EGR (1992-1995 2.2L Beretta, Cavalier, Corsica, Sunfire) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Válvula EGR (1992-1995 2.2L Beretta, Cavalier, Corsica, Sunfire) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 2.2L Chevrolet Beretta: 1992, 1993, 1994, 1995.

- 2.2L Chevrolet Cavalier: 1992, 1993, 1994, 1995.

- 2.2L Chevrolet Corsica: 1992, 1993, 1994, 1995.

- 2.2L Pontiac Sunfire: 1995.

Symptoms Of A Bad EGR Valve

As you're probably already aware, the exhaust gas recirculation (EGR) valve's job is to allow a metered amount of exhaust gas into the intake manifold.

Recirculating the exhaust gas (which is oxygen free) back into the intake manifold reduces the amount of oxides of nitrogen the engine produces (when running).

The exhaust gas recirculation should only happen after the engine has warmed up, under load, and when the fuel injection computer commands the EGR valve solenoid.

When the engine is idling, the EGR valve should be closed, thus preventing any exhaust gas from entering the intake manifold.

When an EGR valve system failure occurs, the fuel injection computer usually sets an EGR valve diagnostic trouble code. If it does, you'll see one of the following OBD I trouble codes:

- Code 32: EGR system problem.

- Code 33: MAP sensor signal High.

You're also going to see one or more of the following symptoms:

- Rough idle.

- Bad gas mileage.

Important Testing Tips

TIP 1: The EGR valve can get very hot (when the engine is running). Start the EGR valve test with a cold engine.

TIP 2: You may need to remove the EGR valve to test it. You can reuse the same EGR valve gasket if it isn't damaged.

Whether you reuse the same gasket or install a new one, you must install the gasket dry. In other words: DO NOT use any sealer (like RTV Silicone) on it.

What Tools Do I Need To Test The EGR Valve

A vacuum pump is the essential tool you'll need to diagnose the EGR valve as good or bad.

If you don't have one, you can borrow one from your local auto parts store (for a small deposit that they'll return to you once you return the tool -AutoZone, O'Reilly Auto Parts).

If you'd like to buy one, this is my recommendation: Actron CP7835 Vacuum Pump.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Checking For Continuous Vacuum To EGR Valve

The EGR valve opens/closes when the fuel injection computer commands the vacuum regulator solenoid to allow/cut off vacuum to the EGR valve.

More specifically, the fuel injection computer commands ON/OFF the vacuum supply to the EGR valve when the engine has warmed up and is under load.

When the engine is idling, the fuel injection computer commands the vacuum supply to be shut off.

For our first test, we'll check that the EGR valve's vacuum line is not supplying vacuum while the engine is idling.

IMPORTANT: Be careful and take all necessary safety precautions while working around a running engine. Think safety all of the time.

Let's get this pot of water boiling:

- 1

Disconnect the vacuum hose that connects to the EGR valve vacuum port.

Leave the other end that connects to the EGR vacuum solenoid connected to it. - 2

Connect a vacuum gauge to the vacuum hose you just disconnected from the EGR valve.

NOTE: If you don't have a vacuum gauge, don't panic. You can still check to see if vacuum is present in the vacuum hose. - 3

Start the engine and let it idle.

- 4

The vacuum hose you just disconnected should NOT have vacuum.

Let's take a look at what your test results mean:

CASE 1: Vacuum WAS NOT present. This is the correct and expected test result since manifold vacuum should NOT be present when the engine is idling.

The next step is to apply vacuum to the EGR valve while the engine is idling. For this test, go to: TEST 2: Applying Vacuum To The EGR Valve.

CASE 2: Vacuum was present. This is a problem since vacuum should not be present when the engine is idling.

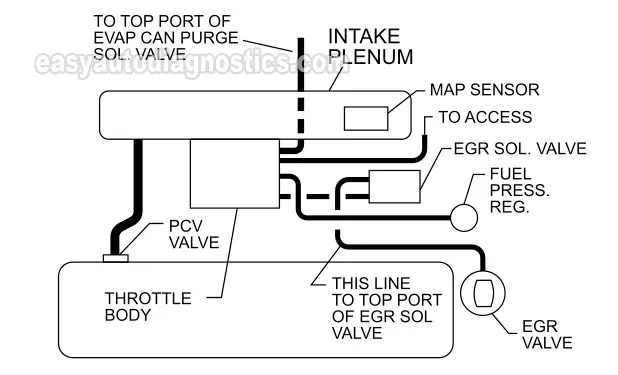

One of two possibilities could be causing the vacuum in the hose. Either the EGR solenoid is defective, or the vacuum hose is attached to the wrong port on the EGR solenoid.

Your next step is to check that the vacuum hose connected to the EGR valve is routed correctly. If the vacuum hose is going to the right place (the EGR vacuum solenoid), your next step is to test the EGR vacuum solenoid.