TEST 3: Testing For The Crankshaft Position Sensor Signal

Now, I'm gonna' show you how to test the crankshaft position sensor. This sensor is known (in most repair/service literature) as the 7X (or 3X) CKP sensor. Although, when you go buy it from your local auto parts store (Auto Zone, O'Reilly, Pepboys, etc.) you'll have to just call it a crankshaft position sensor.

You'll need a digital or analog multimeter (or an oscilloscope) for this test. Also and very important, the battery in the vehicle must be in a fully charged condition.

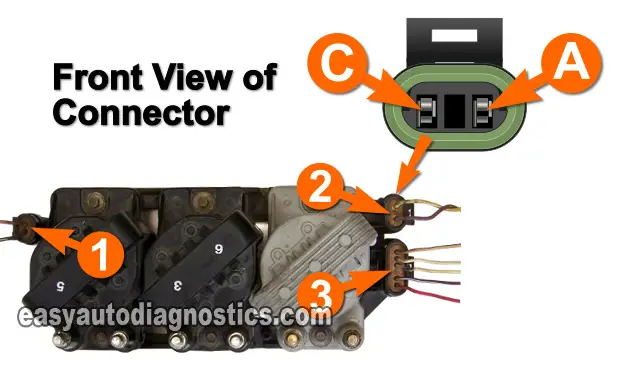

You're gonna' probe both wires at the same time to get an AC voltage reading. This is the A (YELLOW wire) and C (PURPLE wire) circuits of the connector labeled 2 in the photo below.

CAUTION: You'll be working around a cranking engine, use common sense and take all necessary safety precautions.

This is what you need to do:

- 1

Put multimeter in AC Volts mode.

- 2

Disconnect Connector 2 from the ignition control module.

- 3

Connect the red multimeter test lead to the wire that connects to the terminal labeled with the letter A.

- 4

Connect the black multimeter test lead to the wire that connects to the terminal labeled with the letter C.

- 5

Have an assistant crank the engine while you observe the multimeter (or oscilloscope).

- 6

The multimeter's AC reading should fluctuate from 0.3 V AC to 1.0 V AC continuously as the engine is cranking.

The maximum AC voltage attained will depend on the temperature of the engine, oil viscosity and battery charge condition.

If you're using an oscilloscope, the waveform should look like the one at the bottom of the page.

Let's find out what your test results mean:

CASE 1: Your multimeter showed an AC voltage reading. This is the correct test result and it means that the CKP sensor is working properly. In 99% of the cases, this tells you that the ignition control module is defective but not always.

There's still one more test to do (before condemning the ICM) and this is to measure the resistance of the crankshaft position sensor. Go to: TEST 4: CKP Sensor Resistance Test.

CASE 2: Your multimeter DID NOT SHOW an AC voltage reading. Recheck all of multimeter's connections. Try again.

If the multimeter still does not register an AC voltage reading on its screen, the crankshaft position sensor (CKP) sensor is defective. Replace the 3X (7X) crankshaft position sensor.

IMPORTANT: The most common cause of a missing signal is the sensor's wires shorting to Ground on the block or the exhaust manifold. Before you attempt to replace the sensor, remove the wiring from the car and visually check it first. Now, to be little more specific about this issue:

- The crankshaft position sensor connects to the ignition module with two intertwined wires. The length of this wiring harness is about 2 feet long and its routing takes it underneath the rear exhaust manifold.

- Over time and thousands of miles, the fasteners that hold it in place away from the hot exhaust manifold or any sharp edges, breaks.

- What happens next is that the wiring harness comes in contact with the hot exhaust manifold or the sharp edge of the engine block and the insulation of one or both wires starts to either burn off or rub off.

- The end result is that the wires short to Ground and the signal that the CKP sensor is generating never reaches the ignition module.

Therefore, if in this test step your multimeter did not register an AC voltage value, its always a good idea to check for this condition first before replacing the crankshaft position sensor.

If the CKP sensor wires are burned, there are three options available to you:

- Buying a new one from the GM dealership parts department.

- Buying one from a junkyard.

- Repairing the one on your vehicle.