Testing the engine compression is the best way to find out the internal health of the engine.

In this tutorial, I'll explain how to perform the test and more importantly, how to interpret its results.

You'll be able to easily find out if a compression problem is causing a no-start problem or a misfire problem.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L Buick LeSabre: 1995, 1996, 1997, 1998, 1999.

- 3.8L Buick Park Avenue: 1995, 1996, 1997, 1998, 1999.

- 3.8L Buick Regal: 1995, 1996, 1997, 1998, 1999.

- 3.8L Buick Riviera: 1995, 1996, 1997, 1998, 1999.

- 3.8L Chevrolet Lumina: 1998, 1999.

- 3.8L Chevrolet Monte Carlo: 1998, 1999.

- 3.8L Oldsmobile Eighty-Eight: 1995, 1996, 1997, 1998, 1999

- 3.8L Oldsmobile Ninety-Eight: 1995, 1996

- 3.8L Oldsmobile Intrigue: 1998, 1999

- 3.8L Oldsmobile LSS: 1996, 1997, 1998, 1999

- 3.8L Oldsmobile Regency: 1997, 1998

- 3.8L Pontiac Bonneville: 1995, 1996, 1997, 1998, 1999

- 3.8L Pontiac Grand Prix: 1997, 1998, 1999

Tools You'll Need:

- Compression Gauge Tester.

- A Helper

- Pen and Paper

Symptoms Of Low Or No Engine Compression

Engine compression problems usually cause one of two types of problems. You'll either see a misfire problem or a no-start problem.

When an engine compression problem causes a misfire, you'll usually see one or more of the following trouble codes registered in the fuel injection computer's memory (along with the check engine light illuminated):

- P0300 Random Cylinder Misfire.

- P0301 Cylinder #1 Misfire.

- P0302 Cylinder #2 Misfire.

- P0303 Cylinder #3 Misfire.

- P0304 Cylinder #4 Misfire.

- P0305 Cylinder #5 Misfire.

- P0306 Cylinder #6 Misfire.

Generally, when an engine compression problem causes a rough idle, you're only going to feel the problem when you come to a stop light. But as soon as you accelerate the engine, the engine feels fine.

You're also gonna' see:

- Bad gas mileage. This is caused by the simple fact that the engine is now running on less than all 4 cylinders.

- Engine pollutes more. This is also caused by the simple fact that the engine is now running on less than its full complement of cylinders. The live cylinders have to compensate for the 'dead' ones.

If your vehicle is NOT OBD II equipped, you won't have any codes lighting up the check engine light, but you'll definitely feel a rough idle condition.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make two recommendations to you:

1) Which one to buy: The engine compression tester that I have always used is the Actron CP7827 Compression Tester Kit. My only complaint about this engine compression tester is that it does not come with a case to store it in.

2) Where to buy: You can buy an engine compression tester just about anywhere, but you'll end up paying more for it (especially at your local auto parts store). The above links will help you comparison shop. I think you'll agree it's the better way to save money on the compression tester!

TEST 1: 'Dry' Engine Compression Test

The first order of business is to remove the spark plugs. It's important to not remove them if the engine is hot or you run the risk of damaging the spark plug hole threads in the cylinder heads.

If the engine has been running for any length of time, let it cool down completely before removing the spark plugs.

IMPORTANT: You'll be working around a cranking engine, so you have to be careful and stay alert at all times. Think safety all of the time!

These are the test steps:

- 1

Disconnect the ignition control module from its electrical connector. This will prevent the ignition coils from firing off spark to the spark plug wires during the test.

- 3

Remove all 6 spark plugs.

As you're taking them out, be careful and don't drop any of them on the floor, or you could cause the spark plug's ceramic insulator to break, and this will cause a misfire! - 4

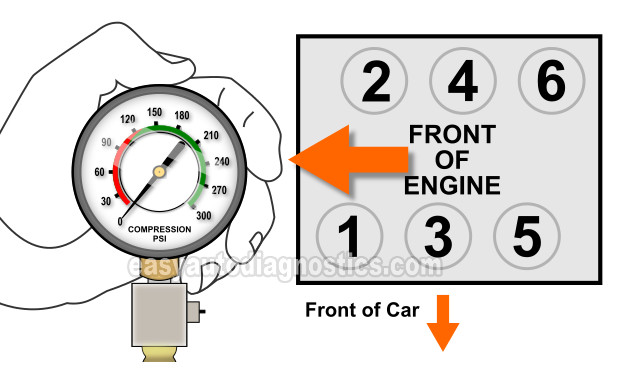

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

NOTE: Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 5

When everything is set up, have your helper to crank the engine. Your job is to keep your eye on the compression tester's gauge.

- 6

Once the needle on the gauge stops climbing, have your helper stop cranking the engine.

- 7

Write down the compression value on a piece of paper. Include the number of the cylinder this reading belongs to.

- 8

Repeat steps 4-7 on the other 3 cylinders.

Let's take a look at what your test results mean:

CASE 1: No compression in 2 or more cylinders. This is not good and it tells you that the engine has serious internal mechanical problems.

The most common causes would be:

- A broken timing chain.

- A blown head gasket.

- The engine threw a rod.

CASE 2: Low compression in one or more cylinders. To a certain point, it's normal for the compression to vary a little between cylinders (as the engine accumulates thousands of miles).

But if these values vary too much, then you're gonna' have a bonafide misfire on your hands.

The next step is to do some math to find out if this low compression value is within a normal parameter or not. Go to: Interpreting Your Compression Test Results.