TEST 2: Testing The Ignition Coil Tower For Spark

It's a common problem for the ignition coil high tension wire to malfunction, resulting in a halt in the transfer of spark from the ignition coil to the distributor cap.

To test the high tension wire indirectly, we can check for spark at the ignition coil tower.

If the ignition coil tower does spark, it'll confirm that the high tension wire is defective as there was no spark when first tested in TEST 1.

Let's begin:

- 1

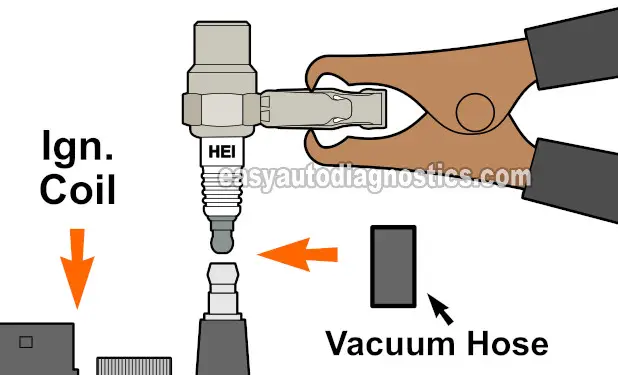

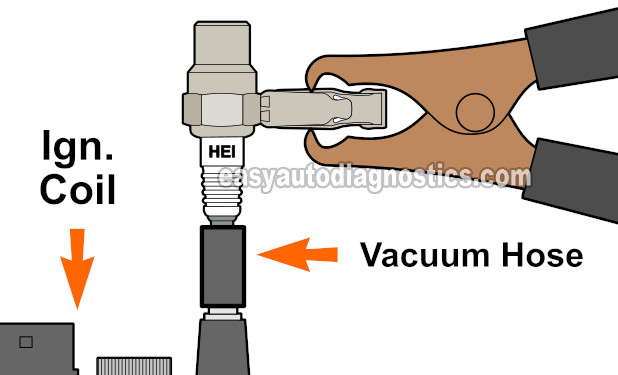

Disconnect the high tension wire from the ignition coil tower.

- 2

Attach the HEI spark tester to the ignition coil tower using a small piece of vacuum hose (see the images above).

NOTE: The vacuum hose must be short enough so that both the HEI spark tester and the ignition coil tower can make metal to metal contact. - 3

Connect the HEI spark tester to the battery negative (-) terminal using a battery jump start cable.

- 4

Have your helper crank the engine while you observe the spark tester from a safe distance.

- 5

You'll get one of two results:

1.) The spark tester will spark.

2.) The spark tester will NOT spark.

Let's take a look at what your test results mean:

CASE 1: The spark tester sparked. This test result tells you that the ignition coil high tension wire is defective and that it needs to be replaced.

Replace the entire set of high tension wires (also known as spark plug wires).

CASE 2: The spark tester DID NOT spark. This test result eliminates the high tension wire as being defective.

The next step is to check that the ignition coil is getting power. Go to: TEST 3: Making Sure The Ignition Coil Is Getting Power.

TEST 3: Making Sure The Ignition Coil Is Getting Power

In order to successfully produce the spark that the spark plugs need to keep the engine running, the ignition coil requires a constant 10 to 12 Volts DC supply.

In this third test, we'll check the power supply to the ignition coil to make sure it's receiving the required voltage.

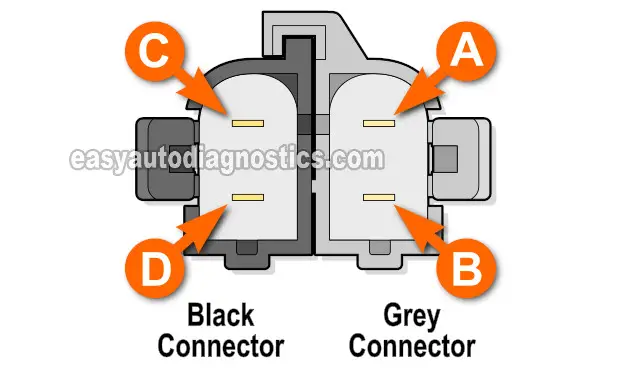

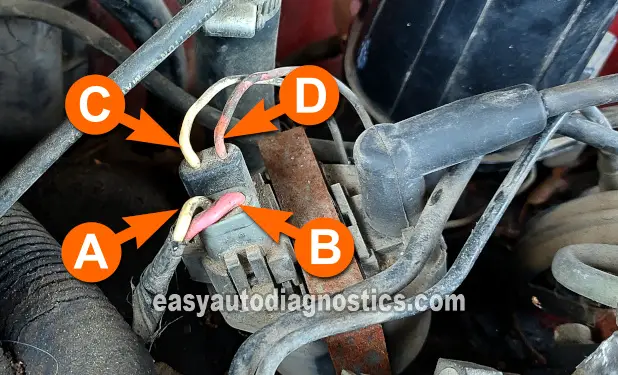

The pink (PNK) wire of the gray connector is the wire that provides the 10 to 12 Volts required to operate the ignition coil.

This PNK wire connects to the male spade terminal, of the gray connector, that I've have marked with the letter B in the illustration above.

We'll run a simple voltage test with a multimeter to determine if the PNK wire of the gray connector is delivering the required 10 to 12 Volts.

Let's begin:

- 1

Disconnect both ignition coil connectors from the ignition coil.

- 2

Place your multimeter Volts DC mode.

- 3

Connect the black multimeter test lead to the battery negative (-) post.

- 4

Turn the key to the ON position but don't start the engine.

- 5

With the red multimeter test lead, probe the male spade terminal of the gray connector that connects to the pink (PNK) wire.

- 6

Your multimeter should now read 10 to 12 Volts DC.

Let's take a look at your test results:

CASE 1: 10 to 12 Volts are present in the pink wire. This test result tells you that the ignition coil is getting 12 Volts.

Your next step is to make sure that the ignition control module (ICM) is activating the ignition coil. Go to: TEST 4: Making Sure The Ignition Coil Is Getting the Activation Signal.

CASE 2: 10 to 12 Volts are NOT present in the pink wire. This test results let you know that the reason that the ignition coil is not sparking is due to a lack of 12 Volts.

Your next step is to find out why these 12 Volts are missing. Once you restore these 12 Volts back to the ignition coil, you should get spark (and the engine started).

TEST 4: Making Sure The Ignition Coil Is Getting The Activation Signal

You've now completed the first three tests and have confirmed that:

- Spark from the ignition coil high tension wire is not present (TEST 1).

- Spark from the ignition coil tower is not present (TEST 2).

- The ignition coil is receiving the necessary voltage of 10 to 12 Volts (TEST 3).

In this final test section, we'll check if the ignition coil is receiving an activation signal, also known as the IC control signal, from the ignition control module (ICM).

The IC control signal is transmitted through the white (WHT) wire of the black connector, which I've labeled with the letter C in the image above.

To verify the presence of this signal, we'll use a 12 Volts automotive test light to measure the voltage on the WHT wire.

NOTE: This test is done with both the black and gray connectors connected to the ignition coil.

Alright, let's wrap it up:

- 1

Connect the test light's crocodile type connector to the battery positive (+) terminal.

- 2

Connect the metal point of the 12 Volt test light to the white (WHT) wire of the black connector.

The WHT wire connects to the terminal labeled with the letter C in the illustration above.

The WHT wire connects directly to the ignition control module and the is the one that delivers the ignition coil activation signal. - 3

Have your helper crank the engine while you observe the 12 Volt test light.

- 4

You'll see one of two things:

1.) The 12 Volt test light flashes ON and OFF.

2.) The 12 Volt test light DOES NOT flash ON and OFF

Let's take a look at your test results:

CASE 1: The 12 Volt test light flashed ON and OFF. This test result confirms that the ignition control module is creating and delivering an activation signal to the ignition coil.

You can conclude that the ignition coil is bad and needs replacement if you have confirmed the following:

- Spark from the ignition coil high tension wire is not present (TEST 1).

- Spark from the ignition coil tower is not present (TEST 2).

- The ignition coil is receiving the necessary voltage of 10 to 12 Volts (TEST 3).

- The ignition coil is receiving an activation signal (this test section).

CASE 1: The 12 Volt test light DID NOT flash ON and OFF. This test result tells you that the ignition control module is not activating the ignition coil.

This test result exonerates the ignition coil, since without this activation signal, it won't spark.

This missing activation signal is usually caused by one of the following issues:

- The ignition control module (ICM) has failed.

- The distributor pickup coil has failed.

The following tutorial will help you test the ICM and pickup coil:

More 4.3L Chevy S10 Pickup, GMC S15 Pickup, And GMC Sonoma Tutorials

You can find a complete list of 4.3L Chevy S10 pickup, GMC S15 pickup, And GMC Sonoma tutorials here:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Fuel Pump (1996-2003 4.3L V6 Chevrolet S10 Pickup, GMC Sonoma).

- How To Test The EGR Valve (1988-1995 4.3L TBI Chevrolet S10 Pickup, GMC S15 Pickup, GMC Sonoma).

- How To Test For A Blown Head Gasket (1988-2003 4.3L Chevrolet S10 Pickup, GMC S15 Pickup, GMC Sonoma).

- How To Test Engine Compression (1988-2003 4.3L V6 Chevrolet S10 Pickup, GMC S15 Pickup, GMC Sonoma).

If this info saved the day, buy me a beer!