How To Interpret The Compression Test Results

The rule of thumb is that the compression between cylinders can not vary more than 15% from each other and if they do then you're gonna' have a genuine misfire condition on your hands or possibly a no-start condition (if more than one cylinder is affected).

How do you figure this out? You can find out by using my online low compression calculator here: Online Low Engine Compression Calculator or manually this way:

- Grab a calculator and multiply the highest compression reading that you recorded by 0.15. So, let's say that cylinder #4 gave you the highest reading of 170 PSI. Well 170 X 0.15 gives you 26 (25.5 rounded off).

- Now, the next step is to subtract 26 from 170, which gives us 144 PSI.

- So then, 144 PSI is the lowest possible compression reading that any one of the rest of the engine cylinders can have. Any compression reading below this and that engine cylinder will misfire.

To make better sense of the above calculation, let's say that my 3.0L Montero produced the following compression test results:

- Cylinder #1 170 PSI.

- Cylinder #2 175 PSI.

- Cylinder #3 170 PSI.

- Cylinder #4 170 PSI.

- Cylinder #5 165 PSI.

- Cylinder #6 120 PSI.

The next step is to do the math: 175 x 0.15= 26, 175-26= 149. So, now I know that cylinder #6 is the one causing the misfire!!

If you do have one or more cylinders with low engine compression (that's causing a problem), your next step is to do a wet compression test. Go to: TEST 2: Wet Compression Test.

TEST 2: Wet Compression Test

Low cylinder compression is due to one of two things: worn/damaged cylinder head valves or worn piston compression rings.

The cool thing is that you and I can pinpoint the problem without tearing into the engine just yet. How? By doing a 'wet' engine compression test.

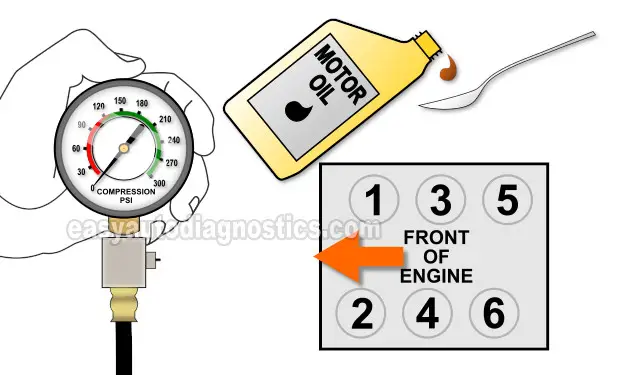

A 'wet' engine compression test simply involves adding a small amount of motor oil to the affected cylinder and then testing its compression once again.

If the low compression problem is in the piston rings, then the oil will help seal the piston rings and cause the compression value to shoot up.

If the low compression problem is due to worn cylinder head valves, then the oil won't be able to seal in the compression and the compression value (on your tester) will remain the same value you recorded/wrote down in the 'dry' compression test.

OK, this is what you'll need to do:

- 1

Add a tablespoon of engine oil in the cylinder you need to retest.

I suggest using a small and long funnel so that the oil will reach the inside of the cylinder. - 2

Once you've added the oil, install the compression gauge

As before just hand tighten the compression gauge. - 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

Repeat steps 1 thru' 4 on any other cylinders that need to be tested.

Let's take a look at what your compression test results mean:

CASE 1: Your compression value shot up This compression test result confirms that the low compression value registered in this cylinder in the dry test is due to worn piston rings.

CASE 2: Your compression value DID NOT shoot up (stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

About Removing The Intake Manifold Plenum

The thing that complicates doing a compression test, on the majority of the 3.0L Mitsubishis covered by this tutorial, is the fact that the upper intake manifold plenum must be removed.

Since I don't include any instructions on this procedure, I want to recommend the following great tutorial on how to do it: CHANGING SPARK PLUGS – MITSUBISHI 3.0 V6 24VALVE (at autofix.com.au).

For the DIY'er that doesn't have a lot of wrenching experience, this might be a job that's best left to an experienced automotive mechanic/technician. Since paying for his expertise may end up saving you from a tremendous headache.

If you do tackle the compression test job, here are some pointers:

- As you're removing bolts, nuts, etc., place them in a container and away from the engine. This is important since you'll want to avoid having anything fall into the open intake manifold runners (that will be exposed when the plenum is removed).

- You WILL NOT be able to place rags in the open intake runners while doing the compression test. Why? Because if you do place rags in the open intake runners (to avoid stuff falling into them) then these rags will get sucked into the cylinder as the engine cranks.

- Use new gaskets. Do not re-use the old intake manifold plenum gasket. Also, when installing the new one, do not coat it in any type of sealer (like RTV Silicon). This is not necessary and could back fire on you since the sealer can cause a vacuum leak.

Yes, testing engine compression on the 3.0L equipped Mitsubishi isn't for the 'faint of heart'. So take all necessary safety precautions and avoid having anything fall into the open intake manifold runners. Or consider letting a professional mechanic do it.

If this info saved the day, buy me a beer!