Low engine compression (in one or several cylinders) is one of the most overlooked tests when troubleshooting a hard to diagnose misfire or no-start condition.

Using a compression tester, you'll be able to measure the pressure of the air that gets compressed inside the cylinders by the piston rings against the cylinder head valves.

If the piston rings or cylinder head valves are worn out, the pressure will leak past them and show up as a low compression value on your compression tester.

In this article, you'll learn how to do both a 'Dry' engine compression test and a 'Wet' compression test and more importantly, how to interpret their results.

Contents of this tutorial:

Symptoms Of Bad Engine Compression

The most direct impact that low compression (or none) in one or two engine cylinders is bad engine idle. Other symptoms include:

- Rough Idle.

- Misfire Condition.

- Check engine light on and one or several of the following misfire codes stored in the PCM memory:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

No compression in all of the cylinders will result in a cranks but does not start condition. The symptoms you'll see will be:

- No Start.

- Everything you test works, for example:

- The Fuel Pump activates and pumps fuel to the fuel injectors.

- The Fuel Injector(s) is (are) being pulsed and injecting fuel into the cylinders.

- The Distributor is sending spark to all spark plugs, which indirectly tells you the ignition coil is good.

- In the COP coil ignition systems, all of the COP coils are sparking.

- If the COP coils are sparking, then this indirectly proves that the crank sensor is OK too.

What Tools Do I Need?

The most obvious tool you'll need, of course, is a compression tester. This bad boy you can rent or buy from your local auto parts store (although the ones they have for rent are so badly beat up they're usually not accurate anymore).

Buying them online is another option that'll save you some money and for the price of what a cheap one will cost at the auto parts store, you can buy one with a case that'll keep your compression tester safe and sound for years to come.

Since the spark plugs have to be removed, you'll need these basic hand tools too:

- Ratchet Wrench.

- 5/8'' Spark Plug Socket.

- Extensions for the Ratchet Wrench.

- Motor Oil (for the 'Wet' compression test part).

- Spark Plug Wire puller.

In case you're needing to buy a compression tester and want to save money by buying it online. You can shop here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Dry Compression Test

If your Suzuki starts and runs, then you need to do the compression test with the engine warmed up. This will ensure a more accurate result from your compression test.

IMPORTANT: The engine should not be hot (normal operating temperature). Why? Well, because you do need to remove the spark plugs (to do the compression test) and removing the spark plugs from a hot engine can strip the threads from the spark plug hole in the aluminum cylinder head.

If the engine doesn't start, you can still do a compression test that will yield results you can use.

OK, this is what you need to do:

- 1

Disable the fuel system.

You can easily do this by simply disconnecting the fuel injector(s) from its (their) electrical connector(s) or disconnecting the fuel pump relay.

NOTE: Disabling the fuel system will prevent the PCM from injecting fuel into the cylinders as you perform the compression test. - 2

Disable the ignition system.

You can easily do this by simply on COP Coil systems: When you remove the COP coils, make sure they're disconnected from their electrical connectors.

On Distributor type systems: Disconnect the ignition coil from its electrical connector.

NOTE: This step is important since it will prevent damage to the ignition coil(s), so don't skip it. - 3

Remove all 4 spark plugs. As you're taking them out, be careful and don't drop any of them on the floor, or you could cause the spark plug's ceramic insulator to break, and this will cause a misfire!

- 4

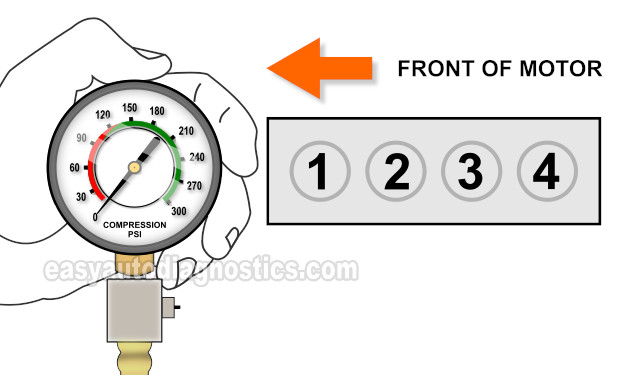

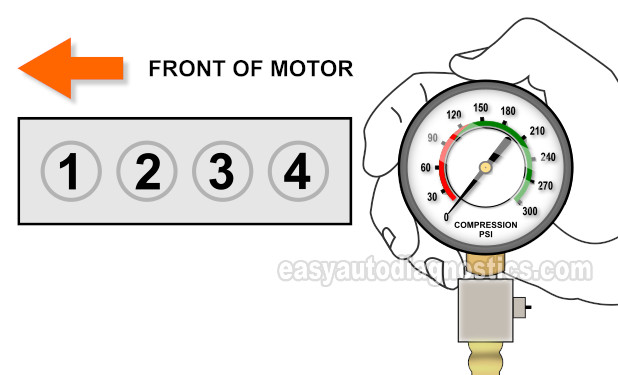

Install the compression tester.

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder. Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 5

When ready, crank the engine as you observe the needle on the compression tester's gauge.

- 6

Once the needle on the gauge stops climbing, have your helper stop cranking the engine.

- 7

Write down the compression value. Record this compression reading on a piece of paper. Include the number of the cylinder this reading belongs to. Now repeat steps 1 thru' 6 on the other cylinders.

Let's interpret your test result:

CASE 1: Your vehicle does NOT start and you got 0 PSI on all cylinders. This test result usually means that the engine has a serious internal mechanical problem.

The engine might have one of the following:

- Timing belt problem.

- Blown head gasket problem.

- Engine threw a rod.

Any compression value below 100 PSI (even if it is not 0 PSI) means internal mechanical engine trouble.

CASE 2: The compression values differ from one another. This could be normal or it could be causing a problem.

To find out if the low compression values are withing a normal range or not, go to: Interpreting The Results Of The Engine Compression Test.

CASE 3: All 4 cylinders have a compression value of less than 100 PSI. This indicates an internal engine problem.

This test result is usually caused by one of the following:

- Timing belt problem.

- Worn piston rings.

- Worn cylinder head valves.

Interpreting The Results Of The Engine Compression Test

There's a good chance that the compression values you got in TEST 1 vary between them. Within a certain range, the variation in the compression values doesn't cause any engine performance problems.

What could cause a problem is if the cylinder compression values vary too much. The cool thing is that we can find out if the variations in the values, you wrote down, indicate a problem (with that cylinder) or not.

The rule of thumb is that they can not vary more than 15% from each other and if they do, you're gonna' have a genuine misfire condition on your hands or possibly a no-start condition (if more than one cylinder is affected).

How do you figure this out? You can find out by using my online low compression calculator here: Online Low Engine Compression Calculator or manually this way:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

To make better sense of the above calculation, let's say that I got the following compression test results:

| Cylinder | Pressure |

|---|---|

| #1 | 175 PSI |

| #2 | 170 PSI |

| #3 | 165 PSI |

| #4 | 120 PSI |

The next step is to do the math:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26.

- STEP 2: 175 - 26= 149.

- ANSWER: 149 PSI is the lowest possible compression value.

Since cylinder #4 is producing 120 PSI, I can conclude that it's the one causing the misfire. The next step is to find out what's causing the low compression value. Go to: TEST 2: Wet Compression Test.

TEST 2: Wet Compression Test

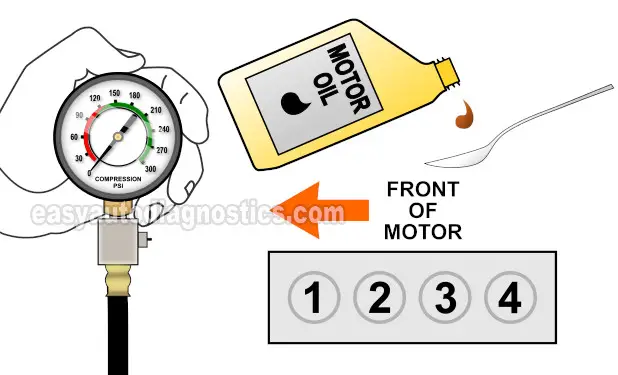

Once you've found out which is the cylinder (or cylinders) with low compression, the next step is to add about 1 to 2 teaspoons of oil to the cylinder and repeat the compression test.

Now, if the reason, why the compression was low, is due to a problem with worn out piston rings, the oil will make the worn out rings seal and the compression value (as recorded by your compression tester) will go up.

If the compression value doesn't go up, then now you know that the problem is in the cylinder head valves and not in the piston rings.

OK, this is what you need to do:

- 1

Add the engine oil to the cylinder with low to no compression.

Remember, you should add about 1 to 2 teaspoons of oil. - 2

Install the compression tester onto the cylinder.

Hand tight is fine. Don't use any type of tool to tighten it. - 3

When all is set up, have your helper crank the engine.

- 4

You'll see one of two results:

1.) Your compression tester will either record a higher reading than the one recorded before.

2.) The compression tester will record the same reading as before.

Let's see what your compression test result means:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn out and thus the problem is in the bottom end.

CASE 2: The compression Value stayed the same. This confirms that the problem is in the cylinder head valves.

Related Articles

You can find a complete list of Suzuki test articles here: Suzuki Index Of Articles.

Here's a list of articles you'll find there:

- How To Test The Ignition Coils Suzuki: Swift, Vitara - Chevy: Metro, Tracker.

- How To Troubleshoot A Misfire (Suzuki 1.3L, 1.6L, 1.8L, 2.0L, 2.3L).

- How To Test The 2.5L COP Coils.

If this info saved the day, buy me a beer!