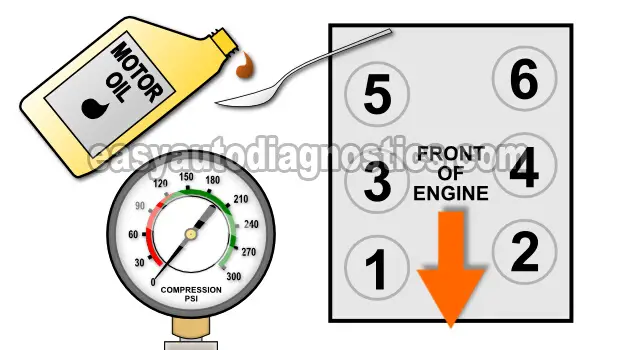

TEST 2: Wet Compression Test

If your compression test results confirm that one or more cylinders has low or no compression, then the next step is to find out if the problem is due to bad cylinder head valves or bad piston rings (of the affected cylinders).

To find out, we need to do a 'Wet' compression test on the cylinders that tested with low or no compression in TEST 1.

A 'Wet' compression test simply involves adding a small amount of motor oil to the low compression cylinder and repeating the compression test.

At the bottom, I'll show you how to interpret your test results.

OK, this is what you'll need to do:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest. I suggest using a small and long funnel so that the oil will reach the inside of the cylinder.

- 2

Once you've added the oil, install the compression gauge, and as before just hand tighten it.

- 3

Now, have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

As before, your job is to keep an eye on the gauge, and you'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

If you have another cylinder that needs to be tested, repeat steps 1 thru' 4 on it now.

Let's take a look at what your compression test results mean:

CASE 1: Your compression test gauge registered a higher compression value on the affected cylinder. This confirms that the low compression value registered in this cylinder in the dry test is due to worn piston rings.

The reason the compression value shot up is due to the fact that the motor oil you just added helped the piston rings to create a tighter seal. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: Your compression test gauge DID NOT register a higher compression value on the affected cylinder (compression stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

Precautions To Take When Removing The Intake Manifold Plenum

Before you remove the intake manifold's plenum (on the 2001 and newer 2.7L engines only), keep in mind several important things:

- Buy or borrow a repair manual (preferably a Haynes Repair Manual -Chilton manuals suck) so that you can have the intake manifold removal process explained in detail.

- The manual will also give you the torque specifications for the bolts.

- Be careful that no foreign object, like a bolt, a nut, or any metal piece/part, falls into the open manifold port runners.

- Once the plenum has been removed, place a clean rag or rags on the open intake runners. This will keep things from falling into them.

- As you're removing bolts, nuts and stuff from the intake plenum to remove it, place them in a container and away from the engine compartment.

Anything falls into the open intake runners, without you knowing, and the engine is started, you are going to be in a big world of hurt! Since it may require the removal of the cylinder head to retrieve the part that fell in. So be alert and be careful.

Removing the plenum is not an out of this world thing that no one can do, it's done around the country in many shops without complications or unhappy endings by simply following some precautions.

If this info saved the day, buy me a beer!