This tutorial will help you perform a dry and wet engine compression test on your 1989-1997 2.3L Ford Ranger.

You'll be able to troubleshoot these two engine performance problems:

- A rough idle condition (misfire condition) due to low compression in one or two cylinders.

- A no-start due to low or no compression on all four cylinders.

The dry and wet engine compression tests will help you determine the internal condition of the engine. The wet compression test will help you pinpoint a low compression test result to either worn cylinder head valves or worn piston rings.

Contents of this tutorial:

![]() You can find this tutorial in Spanish here: Cómo Verificar La Compresión Del Motor (2.3L Ford) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Verificar La Compresión Del Motor (2.3L Ford) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 2.3L Ford Ranger: 1989, 1990, 1991, 1992, 1993, 1994, 1995, 1996, 1997.

- 2.3L Mazda B2300: 1995.

Symptoms Of Bad Engine Compression

The most obvious symptom you'll experience when one or more cylinders have low compression is a rough idle condition or an engine cylinder misfire issue.

Although it doesn't happen all of the time, but if your 2.3L Ford Vehicle is OBD II equipped (1996+), you're gonna' see misfire codes stored in the PCM's memory:

Although it doesn't always happen, if your 2.3L Ford Ranger is equipped with OBD II (1996+) you'll see misfire codes stored in the memory of the PCM:

- Misfire Diagnostic Trouble Codes:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

No compression in all cylinders leads to a 'cranks but does not start' problem. The symptoms you'll see are:

- The engine does not start.

- Everything else works, for example:

- The fuel pump will activate, so you'll see fuel pressure at specification (if testing with a fuel pressure gauge).

- All of the spark plug wires have spark.

- If the coil packs are sparking, then this indirectly proves that the crankshaft position sensor is OK too.

- The PCM will still activate all of the fuel injectors.

What Tools Do I Need?

The most important tool you'll need is a compression tester. You can either rent it at your local auto parts store (Auto Zone, O'Reilly Auto Parts, Advanced Auto Parts, etc.) or buy it online.

Since the spark plugs need to be removed, you'll need some of the following basic tools:

- Ratchet wrench.

- 5/8" spark plug socket.

- Extensions for the ratchet wrench.

- Motor oil (for the wet compression test part).

- Spark plug wire puller.

If you need to buy a compression tester and want to save money, you can shop here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Dry Compression Test

As you're already aware, the 2.3L four cylinder engine in your Ford Ranger (Mazda B2300) comes equipped with 8 spark plugs.

You don't need to remove all eight to do an engine compression test. Remove only the four spark plugs on the exhaust manifold side of the cylinder head.

IMPORTANT: Do not remove the spark plugs from a hot engine. If the engine is hot, let it cool down before removing the spark plugs.

Let's get testing:

- 1

Disable the fuel system. You can easily do this by simply disconnecting the fuel pump relay.

This step is important, so don't skip it. Why? Because it will prevent the PCM from injecting fuel into the cylinders during the compression test. - 2

Disable the ignition system.

You can easily do this by simply disconnecting both coil packs from their electrical connectors.

This step is important since it will prevent damage to the ignition coil packs, so don't skip it. - 3

Remove ONLY the exhaust manifold side spark plugs.

Leave the 4 intake manifold spark plugs in their place.

As you're taking them out, be careful and don't drop any of them on the floor, or you could cause the spark plug's ceramic insulator to break, and this will cause a misfire! - 4

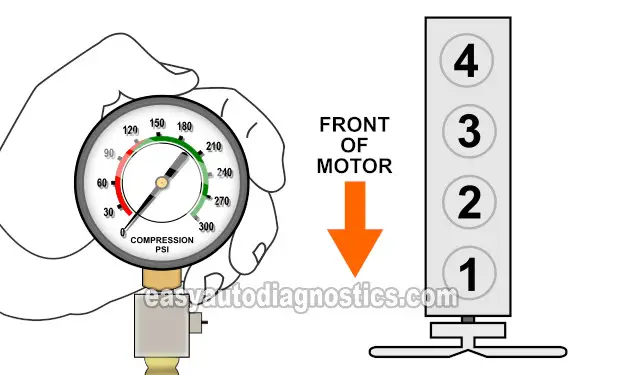

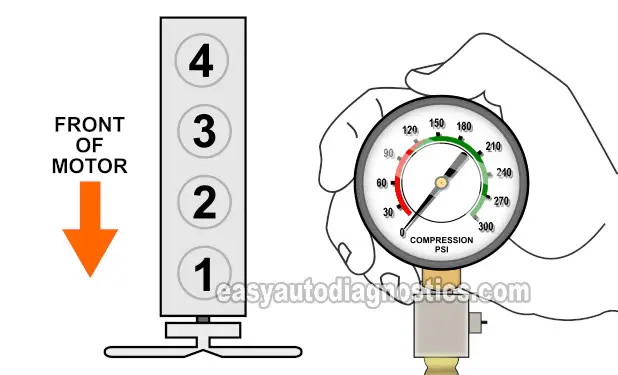

Install the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

NOTE: Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 5

When ready, have a helper crank the engine as you observe the needle on the compression tester's gauge.

- 6

Have your helper stop cranking the engine once the needle on the gauge stops climbing.

- 7

Write down the compression value.

Record this compression reading on a piece of paper. Include the number of the cylinder this reading belongs to. - 8

Now repeat steps 4 thru' 7 on the other cylinders.

Let's take a look at what your test results mean:

CASE 1: You got a reading of 100 PSI or less (less being 0 PSI) on all of the cylinders. This test result tells you that you've got serious engine mechanical problems.

If you have 0 PSI compression on all 4 cylinders it sounds like you have a broken timing belt on your hands. The next step is to remove the timing case cover and check the condition of the timing belt.

What is common when you have a very high mileage engine is low compression across the board. Low usually means anything under 120 PSI (although the service manual says 100 PSI is the minimum). By the time your engine gets to that point, it's also smoking a quart of oil every few days. The other symptoms you'll see is that the idle is very rough.

CASE 2: One or two cylinders gave a low compression reading. This can be normal as not every cylinder delivers the exact same pressure reading. Or those low compression values could cause a problem.

To find out, go to: How To Interpret The Engine Compression Test Results.

How To Interpret The Engine Compression Test Results

Most likely, your compression test results will vary a little (or a lot). If they fluctuate more than 15%, you'll have a misfire or a rough idle problem on your hands.

It's not hard calculate the 15% difference. You can do it in one of two ways:

- Do the math with pen and paper.

- Use my low compression calculator.

If you want to use the low compression calculator, go here: Online Low Engine Compression Calculator.

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that I got the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression reading you got from your engine compression test is in a good range, you need to do the same calculation. Of course, you must use the highest compression value you got, not the one in the example.

Once you've found the 'dead' cylinder, the next step is to figure out what's causing the low compression reading. For this step, go to: TEST 2: Wet Engine Compression Test.

TEST 2: Wet Compression Test

In this section. You'll do a wet compression test on the cylinder(s) that gave a low compression reading.

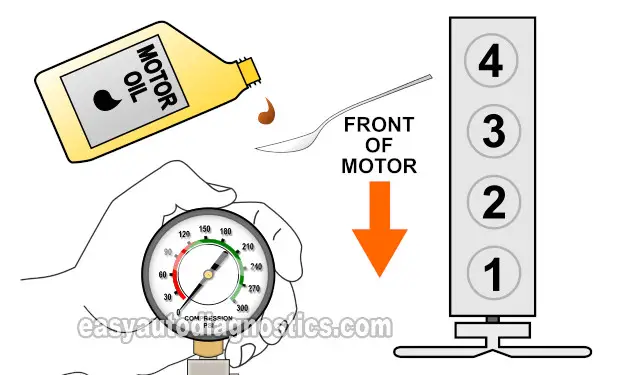

The wet compression test is just a simple variation of the compression test you performed on the previous page. The difference is that you put about 2 tablespoons of engine oil in the low compression cylinder(s).

After adding the engine oil to the low compression cylinder, you'll test its compression again.

If the low compression is caused by worn piston rings, the oil will seal the rings (in the affected cylinder) and increase the compression pressure. This increase in pressure will be clearly visible on your compression tester.

If the problem is worn cylinder head valves, then no amount of oil will seal them and thus the compression reading will remain the same as the dry compression test your performed earlier.

OK, this is what you need to do:

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the dry compression test

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder.

Do not use any type of tool to tighten the compression tester, hand tight is fine. - 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's interpret your test results:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn and therefore the low compression problem is at the bottom.

CASE 2: The compression value remained the same. This confirms that the low compression problem is with the cylinder head valves.

More 2.3L Ford Ranger Diagnostic Tutorials

You can find a complete list of 2.3L Ford Ranger (Mazda B2300) tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The MAF Sensor (1995-1997 2.3L Ford Ranger).

- How To Test The Ignition Module And Crank Sensor (2.3L Ranger, Mustang, B2300).

- Testing The Blower Resistor (1995-1997 2.3L Ford Ranger) .

- How To Test For A Blown Head Gasket (1989-1997 2.3L Ford Ranger).

If this info saved the day, buy me a beer!