In this tutorial, I'll explain how to perform the two different types of compression tests on the Ford Ranger 3.0L V6 engine.

The first test is a dry compression test, which will identify the 'dead' cylinder or cylinders.

After the 'dead' cylinders have been identified, the next step is to perform a wet compression test.

This wet compression test helps determine the source of the low (or zero) cylinder compression test result you obtained from the dry compression test.

Contents of this tutorial:

![]() You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (1995-2008 3.0L Ford Ranger) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (1995-2008 3.0L Ford Ranger) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

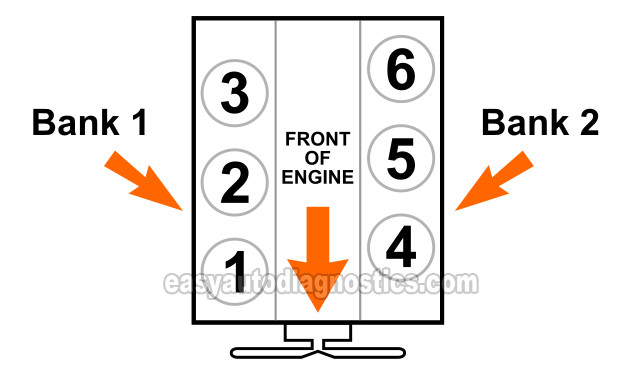

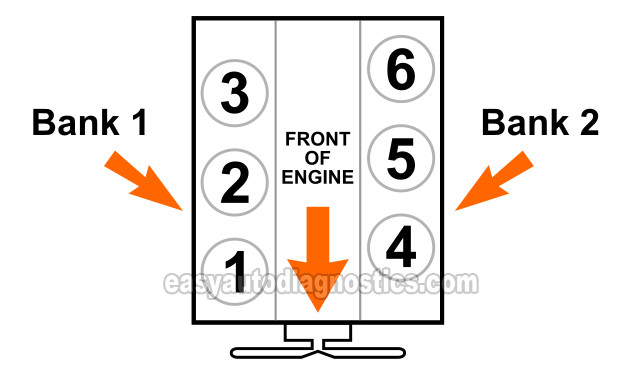

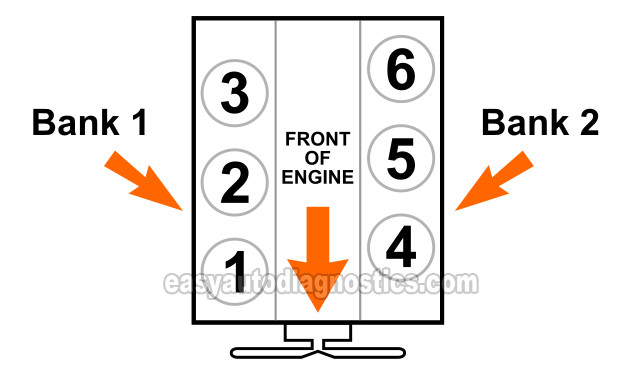

- 3.0L Ford Ranger: 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008.

- 3.0L Mazda B2300: 1994, 1996, 1997, 1998, 1999, 2001, 2002, 2003, 2004, 2005, 2006.

Symptoms Of Engine Compression Problems

What usually causes a cylinder to suffer from low (or no) compression is that its piston rings or cylinder head valves are badly worn or damaged.

Depending on how many of the 6 cylinders are affected by low (or zero) compression, your 3.0L V6 Ford Ranger (or Mazda B3000) engine will either not start or start, but will misfire (or very rough idle).

More specifically, if you have very low (or zero) compression on most engine cylinders, the engine will not start.

Now if you have one or maybe two low compression cylinders, the engine will run, but it will run with a misfire.

Which Compression Tester Should I Buy?

There are many engine compression testers to choose from and many places to buy them. I give you some recommendations:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Dry Compression Test

OK, for our first test, we'll remove all the spark plugs and test the compression on all six cylinders.

You may be wondering if it's necessary to test all six and the answer is no, you don't have to test all of them.

But I suggest you test all six as this will help you get the highest compression reading you need to interpret your compression test results in the next section.

NOTE: It's very important that you remove the spark plugs from a completely cold engine. If you remove the spark plugs from a hot engine, there's a risk of damaging the threads in the spark plug holes (in the cylinder head).

OK, these are the test steps:

- 1

Disconnect the spark plug wires from the spark plugs.

NOTE: Label each spark plug wire with the cylinder number to which it belongs. This will prevent losing the firing order of the spark plug wires. - 2

Remove the spark plugs from the engine.

When removing the spark plugs, be careful not to drop any of them on the floor, otherwise you risk cracking the spark plug's porcelain insulator (then you'll have a misfire on your hands). - 3

Install the engine compression gauge into the spark plug hole for engine cylinder number 1.

NOTE: Only tighten the compression gauge by hand! Don't use any tool to tighten it. - 4

Have your helper crank the engine until the needle on the compression gauge stops rising.

- 5

Write down the value at which the needle stopped and the number of the engine cylinder on a piece of paper.

- 6

Repeat test steps 3 through 5 on the remaining cylinders.

Let's see what your test results mean:

CASE 1: You got 0 PSI compression on all cylinders. This test result is usually the result of mechanical damage in the engine.

The most likely causes are:

- Timing chain problem.

- Blown cylinder head gaskets.

- Engine threw a rod.

Any compression reading below 100 PSI (even if it doesn't go down to 0 PSI) indicates internal mechanical engine problems.

CASE 2: You got uneven compression readings between engine cylinders. The next step is to find out if any of these values are too low and causing a problem.

To find out, go to: Interpreting Compression Test Results.

Interpreting Compression Test Results

One of the things that probably caught your attention right away (when you finished the compression test on your Ford Ranger) is that the compression results from each cylinder vary a little or a lot.

To a certain extent, this deviation is normal and does not cause any problems. When the fluctuation is large, the engine runs rough at idle or misfires.

The cool thing is that interpreting the compression test results is pretty easy, and in this test section, I'll explain how to do it.

In short, we want to find out what is the lowest possible compression value that a cylinder can have before it misfires. As a rule of thumb, the lowest compression value should NOT differ by more than 15% from the highest compression value.

How do you find out? You can find out with pen and paper or by using my online low compression calculator here:

To figure it out manually, I'll use an example. Let's say my Ford Ranger's engine produced the following compression readings:

- Cylinder #1 175 PSI.

- Cylinder #2 165 PSI.

- Cylinder #3 160 PSI.

- Cylinder #4 120 PSI.

- Cylinder #5 160 PSI.

- Cylinder #6 155 PSI.

The next step is to perform the following math:

- Multiply 0.15 (15%) by the highest value: 175 x 0.15. That's 26.25, but we round it up to 26.

- Next we subtract 26 from 175: 175 - 26 = 144.

- So now we know that the lowest possible compression value is: 144 PS.

This means that cylinder #4 with a compression reading of 120 PSI is the one causing the misfire (P0304 trouble code) as it is below the 144 PSI minimum.

Once we've found the 'dead' cylinder, the next step is to figure out what's causing the low compression reading. For this step go to: TEST 2: Wet Compression Test.

TEST 2: Wet Compression Test

As previously mentioned, a cylinder will have a compression problem when its piston rings are badly worn or its cylinder head valves are badly worn/damaged.

To find out, we'll put a few drops of oil in the 'dead' cylinder and test its compression again.

If the piston rings are badly worn and causing the low or zero compression result in TEST 1, then you'll see the compression reading shoot up with the oil in the cylinder.

If the compression test reading does NOT increase, you can conclude that the problem is caused by worn/damaged cylinder head valves.

OK, this is what you need to do:

- 1

Put a tablespoon (or two) of engine oil in the cylinder you want to retest.

I suggest using a small and long funnel so that the oil reaches the inside of the cylinder. - 2

Install the compression gauge and tighten only hand-tight.

- 3

Have your helper crank the engine until the needle stops rising on the compression gauge.

- 4

You'll see one of two results:

1.) The needle rises higher than the previous compression number you recorded for that particular cylinder.

2.) The needle doesn't move at all or stays on the same number you recorded earlier.

Whatever value your compression tester reads, write it down again. - 5

Repeat steps 1 through 4 on any other cylinder you need to test again.

Let's analyze your compression test results:

CASE 1: The compression value shot up. This test result lets you know that extremely worn piston rings are the cause of the low compression reading in this particular cylinder.

The reason the compression reading shot up is because the engine oil you just added helped the piston rings create a tighter seal. This type of test result only occurs when the problem is due to worn piston rings.

CASE 2: Your compression value DID NOT increased (stayed the same). This test result lets you know that the cylinder head valves on that cylinder are worn/damaged and are the ones causing the low compression reading in that particular cylinder.

More 3.0L Ford Ranger Tutorials

You can find a complete list of 3.0L Ford Ranger tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- Tune Up And Torque Specifications 1991-1994 3.0L Ford Ranger.

- How To Test The TPS (1993-1994 3.0L Ford Ranger).

- How To Test The Fuel Injectors (1992-1994 3.0L Ford Ranger).

- How To Test The Fuel Pump (1992-2000 3.0L Ford Ranger) (at: troubleshootmyvehicle.com).

If this info saved the day, buy me a beer!