This tutorial will show you how to test the continuity of all four circuits that connect the EEC Power Relay to the PCM, ignition switch, battery, and Ground.

These step-by-step tests apply to 1985–1991 4.9L, 5.0L, and 5.8L F-Series trucks —and they use nothing more than a digital multimeter and a little patience.

These tests will help you pinpoint common problems like blown fusible links, voltage drops, and open wires that can prevent the PCM from powering up.

So, if you're chasing down a no-start or fuel system issue, this guide will help you confirm the wiring is doing its job —or point you straight to the problem.

Contents of this tutorial:

- EEC Power Relay Circuit Descriptions.

- Precautions To Take When Testing The PCM To Relay Circuits.

- TEST 1: Checking The Continuity Of The KAPWR Circuit.

- TEST 2: Checking The Continuity Of The IGNITION Circuit.

- TEST 3: Checking The Continuity Of The VPWR Circuit.

- TEST 4: Checking The Continuity Of The GROUND Circuit.

- Location Of The EEC Power Relay Ground Point.

- More Ford F-Series Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

F150:

- 4.9L L6 Ford F150 Pickup: 1987, 1988, 1989, 1990, 1991.

- 5.0L V8 Ford F150 Pickup: 1985, 1986, 1987, 1988, 1989, 1990, 1991.

- 5.8L V8 Ford F150 Pickup: 1988, 1989, 1990, 1991.

F250:

- 4.9L L6 Ford F250 Pickup: 1987, 1988, 1989, 1990, 1991.

- 5.0L V8 Ford F250 Pickup: 1985, 1986, 1987, 1988, 1989, 1990, 1991.

- 5.8L V8 Ford F250 Pickup: 1988, 1989, 1990, 1991.

F350:

- 4.9L L6 Ford F350 Pickup: 1987, 1988, 1989, 1990, 1991.

- 5.8L V8 Ford F350 Pickup: 1988, 1989, 1990, 1991.

EEC POWER RELAY TESTS:

EEC POWER RELAY CIRCUIT WIRING DIAGRAMS: These diagrams go hand-in-hand with the tests in this tutorial and are meant to be used alongside it.

- ECM Power And Ground Circuits Wiring Diagram (1985-1986 5.0L V8 F-Series Pickup).

- ECM Power And Ground Circuits Wiring Diagram (1987 4.9L, 5.0L V8 F-Series Pickup).

- ECM Power And Ground Circuits Wiring Diagram (1988 4.9L, 5.0L, 5.8L F-Series Pickup).

- ECM Power And Ground Circuits Wiring Diagram (1989 4.9L, 5.0L, 5.8L F-Seris Pickup).

- ECM Power And Ground Circuits Wiring Diagram (1990-1991 4.9L, 5.0L, 5.8L F-Series Pickup).

EEC Power Relay Circuit Descriptions

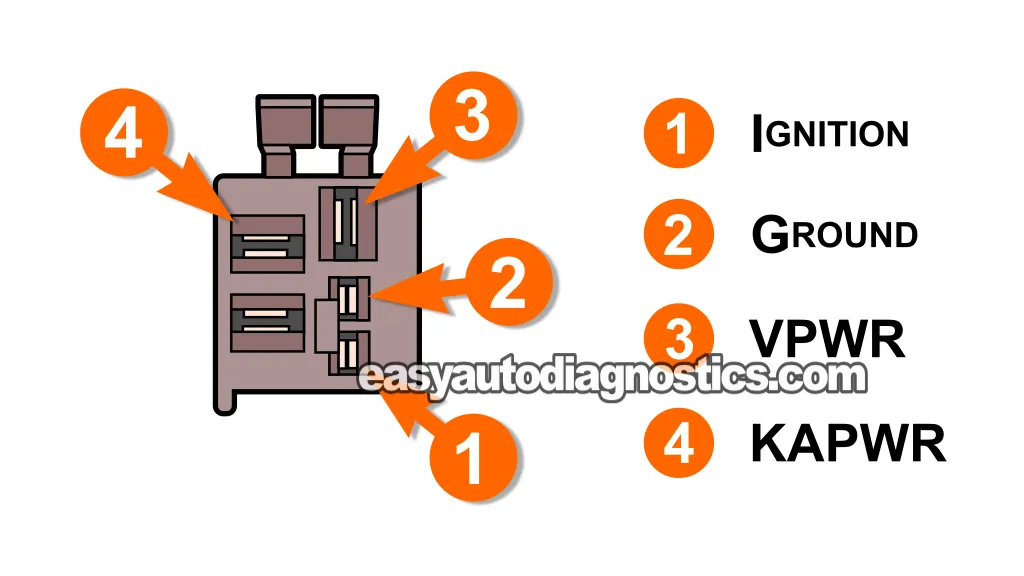

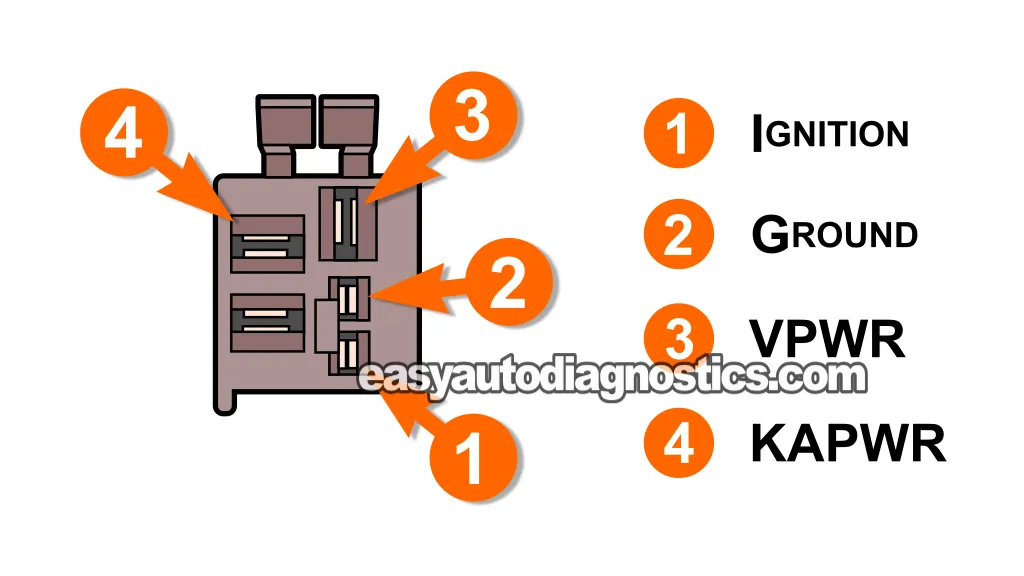

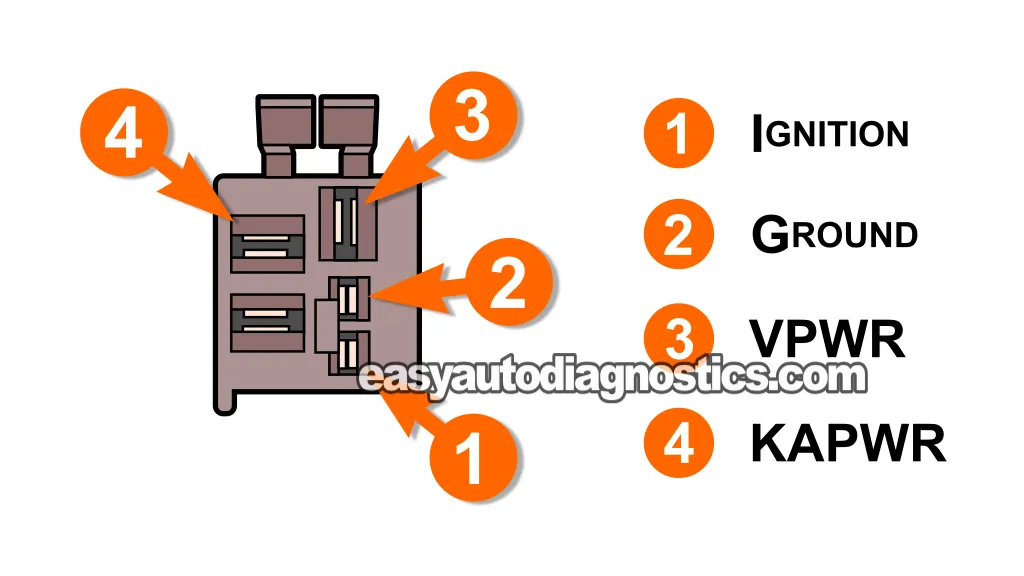

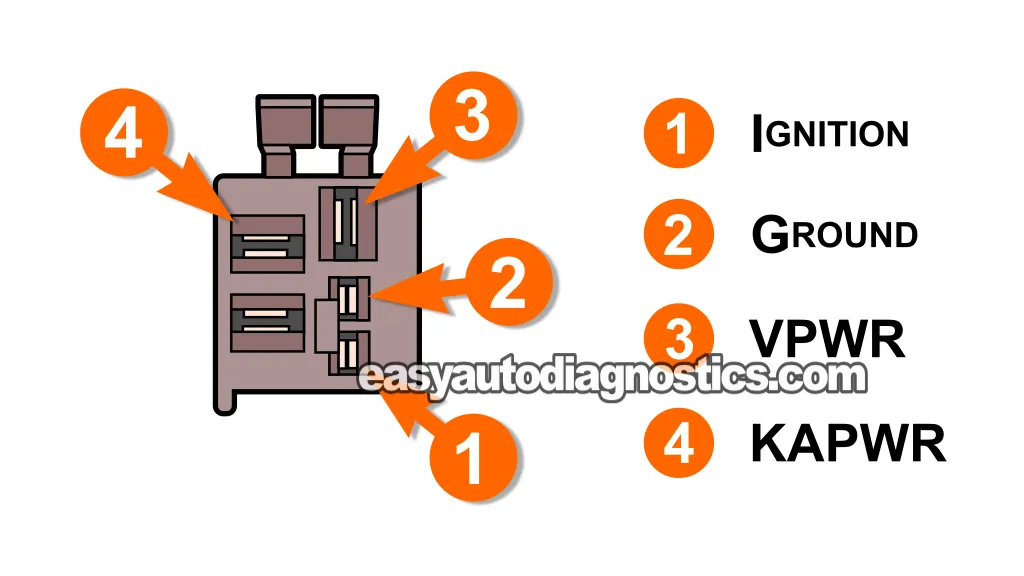

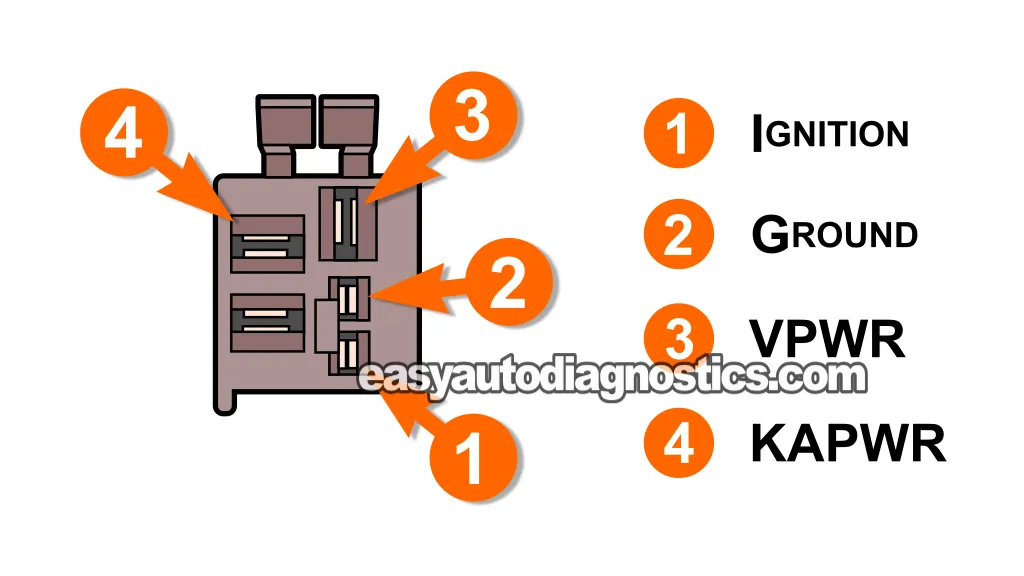

The EEC Power Relay on the 1985–1991 Ford F-Series pickups uses a 5-terminal connector, but only 4 terminals are actually used —and this connector is the same across all these model years, regardless of engine size (4.9L, 5.0L, or 5.8L).

From the factory, this relay was brown in color —which is why it's commonly referred to as the "Brown Relay". Its connector, located in the engine compartment, is also brown.

Over the years, many of these relays have been replaced with aftermarket versions, which are often gray (or black). So don't worry if yours isn't brown —as long as it's plugged into the brown EEC Power Relay connector under the hood, it's all good.

Here's a breakdown of each terminal and its job in the circuit:

- 1 —Ignition.

- Ignition switch 12 Volts input. Power only in RUN or START.

- 2 —Ground.

- This is a chassis Ground and is available at all times.

- 3 —Vehicle Power (VPWR).

- 12 Volt output of the EEC Power Relay.

- 4 —Keep Alive Power (KAPWR).

- Battery 12 Volts input. Power at all times.

Now that you know what each terminal does, let's go over a few important precautions before testing any of these circuits.

Precautions To Take When Testing The PCM To Relay Circuits

Before performing any continuity tests between the EEC Power Relay and the PCM, it's important to take a few precautions to avoid damaging the connectors —especially the PCM's 60-pin connector.

Never use standard multimeter test leads to probe the female terminals inside the PCM connector. The metal tips are usually too thick and can permanently stretch or damage the terminals.

If the PCM connector or relay connector terminals get damaged, you could end up with poor contact or an intermittent issue that's gonna be hard to track down —and that's a nightmare you definitely don't need.

Instead, use a test probe with a thin needle such as a back-probe. These are safe to insert into the PCM connector without deforming the terminals.

Recommended Probes: This is the probe kit I personally own and use in my diagnostic work. I remove the needle from the wire-piercing probe (it comes apart in two pieces) and use it to safely probe PCM terminals and other small-diameter connectors. The needle is thin enough to avoid damaging tight-fitting female terminals. It's affordable, reliable, and a great tool to have in your kit —especially for sensitive connectors like the PCM's 60-pin connector.

- Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link)

Buying through these links helps support this site and keeps these tutorials coming —at no extra cost to you. Thanks so much!

TEST 1: Checking The Continuity Of The KAPWR Circuit

The EEC Power Relay needs a solid 12 Volt power source straight from the battery to do its job, and this power supply is called Keep Alive Power (KAPWR) by Ford.

If that power supply wire isn't delivering 10 to 12 Volts, even if the relay is good, it won't be able to send power to the PCM —and your truck won't start.

So, for our first test, we're going to use a multimeter to check the continuity of this wire and confirm it can actually carry power from its starting point at the starter motor relay to terminal 1 of the EEC Power Relay connector.

IMPORTANT: Before doing this test, check for 10 to 12 Volts DC at terminal 1 of the EEC Power Relay connector (yellow wire). If voltage is present, the KAPWR circuit is working and there's no need to go further —you can skip to TEST 2. If there's no voltage, then continue with this test to check the continuity of the KAPWR feed circuit.

Alright, let's get this show on the road:

- 1

Disconnect the battery negative (-) terminal from the negative (-) post.

NOTE: The negative (-) battery terminal must remain disconnected for all tests. - 2

Disconnect the EEC Power Relay from its connector.

- 3

Locate the yellow (YEL) wire.

The YEL wire is the KAPWR wire. - 4

Set your multimeter to Ohms mode.

NOTE: For the most accurate result, don't use the "continuity" setting of your multimeter (if it has one), place the multimeter in Ohms mode to get the most accurate test result. - 5

Probe the female terminal I've labeled with the number 1 with the red multimeter lead.

- 6

Probe the battery positive (+) terminal with the black multimeter lead.

- 7

Your multimeter should show 5 Ohms or less.

Now, let's make sense of what you just measured:

CASE 1: Your multimeter registered 5 Ohms or less. This is the correct result.

It means the YEL wire between the EEC Power Relay connector and the battery positive (+) terminal (through the inline fusible link) is intact and capable of carrying current without any problems.

Your next step is to check the IGNITION circuit. Go to: TEST 2: Checking The Continuity Of The IGNITION Circuit.

CASE 2: Your multimeter registered infinite resistance. This tells you the YEL wire is "open" somewhere between the EEC Power Relay connector and the starter motor relay —where the inline fusible link connects to battery power.

An open-circuit here means the PCM will never receive power from the relay, resulting in a no-start condition.

This is usually caused by the KAPWR wire's 20-gauge inline fusible link being blown. Your next step is to inspect all of the inline fusible links connected at the starter motor relay and find the one that's blown or burned out —then replace it with the same gauge inline fusible link.

CASE 3: Your multimeter registered more than 5 Ohms, but not infinite. This usually means the KAPWR circuit wire has resistance due to corrosion somewhere in the circuit.

While this isn't necessarily a bad thing, since the circuit is till able to carry some voltage, the voltage drop could be enough to cause intermittent PCM issues —and it's gotta be fixed.

The most likely cause of this issue is corrosion on the round terminals of the battery cable or inline fusible links where they connect at the starter motor relay. Lightly sand all of the terminals with low-grit sandpaper, reconnect them, and retest.

TEST 2: Checking The Continuity Of The IGNITION Circuit

The EEC Power Relay needs ignition-switched power to activate in both the RUN and START key positions —it comes in on terminal 1 through the IGNITION circuit wire, which varies by model year:

- 1985–1989: white with blue stripe (WHT/BLU) wire.

- 1990–1991: red with light green stripe (RED/LT GRN) wire.

Before testing the circuit, check for 10–12 Volts DC at terminal 1 of the EEC Power Relay connector with the key in the ON position.

If voltage is present, the IGNITION circuit is working and there's no need to go further —you can skip to TEST 3.

If there's no voltage at terminal 1 with the key ON, then we need to check the continuity of the ignition switch circuit that feeds it.

This test will help you determine if there's an open-circuit issue somewhere between the battery, ignition switch, and the EEC relay connector.

OK, let's begin:

- 1

Disconnect the battery negative (-) terminal from the negative (-) post.

NOTE: The negative (-) battery terminal must remain disconnected during this entire test. - 2

Turn the key to the RUN position.

- 3

Disconnect the EEC Power Relay from its connector.

- 4

Locate the WHT/BLU or RED/LT GRN wire at terminal 1 of the EEC Power Relay connector.

- 5

Set your multimeter to Ohms mode.

- 6

Connect the red multimeter test lead to the battery positive (+) terminal.

- 7

Probe the female terminal I've labeled as number 4 using the black multimeter lead.

- 8

Your multimeter should register between 5 and 30 Ohms.

- 9

Repeat the test with a helper holding the key in the START position.

- 10

Your multimeter should again register between 5 and 30 Ohms.

Now, let's look at what your multimeter just told you:

CASE 1: Your multimeter shows between 5 and 30 Ohms in both the RUN and START positions. This is the correct and expected result for this circuit. It means the ignition switch is allowing current to pass through with acceptable resistance, and the circuit is not open in either position.

You can now move on to: TEST 3: Checking The Continuity Of The VPWR Circuit.

CASE 2: Your multimeter shows infinite resistance in either the RUN or START position. This means the IGNITION circuit is open somewhere between the battery, ignition switch, or the EEC Power Relay connector.

On 1987–1991 pickups, this usually comes down to one of two things:

- The inline fusible link that feeds the ignition switch is blown. This fusible link is located at the starter motor relay. Go ahead and check all of the fusible links connected there and see if one is burned out.

- The ignition switch is bad and no longer completing the circuit in that key position.

On 1985–1986 pickups, this result is usually caused by one of the following three issues:

- The inline fusible link that feeds the ignition switch is blown. Like later models, this link is located at the starter motor relay —check each one for a burn-out.

- The 1.1 Ohm (Ω) resistance wire that connects the I1 and I2 slots of the ignition switch connector is burned out.

- The ignition switch itself is faulty and isn't completing the circuit in that key position.

TEST 3: Checking The Continuity Of The VPWR Circuit

The VPWR wire delivers power from the EEC Power Relay (once it has activated and turned on) to the ECM, fuel injectors, fuel pump relay, and a bunch of other components.

If this circuit is open, the ECM, the fuel system, and several other systems won't activate —and the engine won't start.

We'll be testing continuity between terminal 3 of the relay connector and pins 5, 37, and 57 of the PCM's 60-pin connector.

IMPORTANT: Never insert standard multimeter test leads into the PCM connector terminals —they're too thick and can permanently damage the female pins.

To probe them safely, I recommend using thin back probes. The needle-like metal tips are small enough in diameter to fit into the PCM connector's female terminals without causing damage.

Alright, let's get going:

- 1

Disconnect the battery negative (-) terminal from the negative (-) post.

NOTE: The negative (-) battery terminal must remain disconnected for all tests. - 2

Disconnect the EEC Power Relay from its connector.

- 3

Disconnect the ECM from its 60-pin connector.

- 4

Locate the red (RED) wire at terminal 3 of the relay connector.

On the 1985 and early 1986 pickups, this wire may be red (RED) or a dark blue (DK BLU) wire. - 5

Set your multimeter to Ohms mode.

- 6

Connect the red multimeter test lead to the female terminal I've labeled as terminal 3 of the relay connector.

- 7

At the PCM's 60-pin connector, carefully probe pin 5 with the black multimeter test lead using a thin back-probe or adapter.

NOTE: By pin, I mean the female terminal of the computer's 60-pin connector and not the male terminals on the computer itself. - 8

Repeat the test for pins 37 and 57. You should get similar results on all three pins —they're all powered by the same VPWR wire.

- 9

Your multimeter should register less than 5 Ohms for each pin (5, 37, and 57).

Here's how to interpret your results:

CASE 1: Your multimeter shows less than 5 Ohms for each pin (5, 37, and 57). This is the correct result. The VPWR circuit is intact and capable of delivering power to the ECM, fuel pump relay, injectors and anything else connected to this circuit.

Let's move on to our last test: TEST 4: Checking The Continuity Of The GROUND Circuit.

CASE 2: Your multimeter shows infinite resistance on all three pins. This means the VPWR wire is completely open between the EEC Power Relay connector and the PCM.

- On 1985–1988 F-Series pickups: This is usually caused by a blown 20-gauge inline fusible link protecting this circuit —check and replace it if needed.

- On 1989–1991 F-Series pickups: These don't use a fusible link for this circuit, so an infinite reading means the wire itself is open and must be traced and repaired.

CASE 3: Your multimeter shows more than 5 Ohms but not infinite. This means the VPWR wire has corrosion somewhere along its path, creating unwanted resistance in the circuit.

This isn't necessarily a complete failure of the circuit, since it's not open. This issue usually points to corrosion inside the wire, and depending on how badly the copper strands are corroded (green copper corrosion), it may not deliver full voltage under load. That kind of voltage drop can lead to random fuel injection issues or engine performance problems.

TEST 4: Checking The Continuity Of The GROUND Circuit

The EEC Power Relay needs a clean, solid Ground to work properly —and it gets that Ground through terminal 2 of its connector.

This Ground is always present; it doesn't come from the PCM —it's a direct chassis Ground.

In this test, we're going to use a multimeter to perform a simple voltage drop check across the Ground circuit.

This is more reliable than checking Ohms, especially for spotting hidden corrosion that causes problems under load.

If the Ground circuit has corrosion or rust, it can prevent the relay from activating —even though everything else checks out.

Let's put this into action:

- 1

Reconnect the battery negative (-) terminal to the battery post.

- 2

Set your multimeter to Volts DC mode.

- 3

Measure battery voltage directly at the battery posts and make a note of it —this is your reference voltage.

- 4

Connect the red multimeter lead to the battery positive (+) terminal.

- 5

Probe terminal 2 of the EEC Power Relay connector with the black multimeter lead.

NOTE: Double-check this terminal has a black (BLK) or black with light green stripe (BLK/LT GRN) wire connecting to it. - 6

Your multimeter should register the same voltage (or nearly the same) as the battery voltage you saw in step 3.

Let's see what this is pointing to:

CASE 1: Your multimeter shows the same voltage (or nearly the same) as the battery voltage. This is the correct result. It confirms that the EEC Power Relay's Ground circuit is solid and clean, with no excessive resistance or voltage drop.

The relay will have a proper return path to Ground. If all four circuit tests passed, you're done —all relay circuits are in good shape.

CASE 2: Your multimeter shows 0 Volts. This means the Ground wire is completely disconnected or broken between the relay and the chassis.

Without a Ground, the EEC Power Relay can't complete its circuit and won't operate. Inspect the Ground wire's connection to the body or battery negative (-) terminal for corrosion, a loose bolt, or a broken terminal.

For the locations of the Ground point of the BLK or BLK/LT GRN wire, see this section: Location Of The EEC Power Relay Ground Point.

CASE 3: Your multimeter shows some voltage, but it's much lower than the battery voltage. This means the Ground path exists but has corrosion or rust somewhere in the connection —creating resistance.

This kind of poor Ground can cause the relay to not activate. Clean the Ground point and make sure it has solid metal-to-metal contact.

Location Of The EEC Power Relay Ground Point

Here's where the EEC Power Relay's Ground wire —either the black (BLK) or the black with light green stripe (BLK/LT GRN) wire— bolts down on 1985–1991 F-Series pickups.

Sometimes that bolt comes loose, or the terminal gets corroded. A quick clean-up with light-grit sandpaper and a wrench to snug the bolt can solve weird power issues fast.

- 1985-1986: At battery negative (-) cable terminal.

- 1987-1989: At left hand side of engine compartment, inner fender and behind the headlamp.

- 1990-1991: At left hand side of engine compartment, on upper radiator support.

IMPORTANT: One of the most common problems I've run into on these older F-Series trucks is a missing chassis Ground. From the factory, the battery's negative (-) cable connects to both the engine and the chassis.

But over the years, that cable often gets replaced —and sometimes, the replacement only connects to the engine. When that happens, the chassis loses its Ground, and on 1987–1991 models, the EEC Power Relay grounds to the chassis. No chassis Ground means the relay won't work right— or at all.

If your truck's negative (-) cable only grounds to the engine, you'll need to add two Ground wires: one from the battery negative (-) terminal to the inner fender, and another from the engine block to the firewall or inner fender. It's a simple fix, and it can save you hours of frustrating electrical gremlins down the road.

More Ford F-Series Pickup Tutorials

You can find a complete list of Ford F-Series pickup wiring diagrams and tutorials in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The MAP Sensor (Ford F150, F250, F350).

- How To Test The Ford Fuel Pump Relay -No Start Troubleshooting (Green Relay).

- How To Test The Ford Ignition Control Module.

- How To Test The Ford Ignition Control Module (Distributor Mounted).

If this info saved the day, buy me a beer!