Checking Engine Compression

One of the things that is so easy to overlook, in diagnosing a misfire condition, is the mechanical condition of the engine. Over the years I've been able to nail down misfires that other technicians hadn't been able to diagnose because they never thought to do a compression test on the engine cylinders.

If the compression of one cylinder is lower than that of the other engine cylinders, that car or truck is gonna' suffer a misfire that no matter what gets replaced, it will continue to misfire.

So then, this was the next test that I performed (in my diagnostic):

- I removed all of the spark plugs.

- I unplugged all of the fuel injectors (so that they would not spray fuel into the cylinders as the engine was cranked).

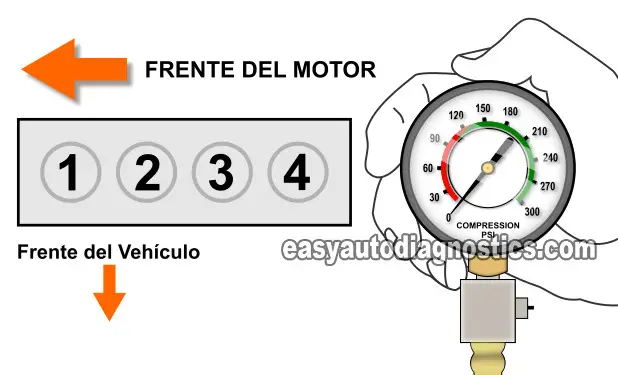

- I attached the compression gauge to cylinder #4 first.

- Then, had my buddy crank the engine till the needle on the compression gauge stopped climbing.

- Wrote down the number at which the needle of the compression gauge stopped and repeated the test with the other cylinders.

The results I got where cylinder #1 -240 PSI, cylinder #2 -240 PSI, cylinder #3 245 PSI, cylinder #4 240 PSI. The readings are pretty much the same across all of the cylinders. This result confirmed that the engine's mechanical condition (compression at least) was OK and not the cause of the misfire condition.

What if the compression readings varied a lot between cylinders? Let's say that the compression reading for cylinder #4 was 80 PSI or 100 PSI with the rest of the other cylinder's readings hovering at 240 PSI. What would this tell me?

This result would tell me that the reason for the misfire on cylinder #4 was due to an engine mechanical fault. My rule of thumb (proven true over the years) is that engine compression can not vary more than 10% between cylinders. This is what I do to find out what is the lowest acceptable reading:

- I take the highest compression gauge reading, which in the case of the Grand Am was: 245 PSI.

- I then pull out a calculator and multiply 245 by 10% (or .10).

- In this case the result would be: 24.

- I then subtract 25 from 245 and get: 220 PSI.

From personal experience, I can tell you that if the compression reading is at or near or below the minimum compression, you have got some mechanical issue in that cylinder that is going to affect idle and/or cause a misfire.

So What's Next?

OK, another test and I still had not found the problem. Now, all of this reading (I know, my articles really do seem long but if you notice, each paragraph usually consists of one sentence each for the most part) might make you think that I had spent all day testing all of these components (in reality only about 45 minutes had gone by).

But, it's only thru' testing and interpreting the results of those tests that you're able to proceed to the next step, which was to swap the ignition coils.

Swapping The Ignition Coils

Even though I got spark from all of the spark plug boots (per the instructions of TEST 1) and this ‘all spark’ result indicated the ignition coils were good, I still had a feeling that the problem lay in the ignition system.

From previous experience (over many years) I know that the Quad 4 ignition system is a very difficult beast to tame and unlike other GM ignition systems, there are no absolute truths with this type of ignition setup.

So again, knowing just how problematic the Quad 4 ignition system is, I decided to test the ignition coils again, but by a different method. And it was this method that finally provided the answer to my troubleshooting.

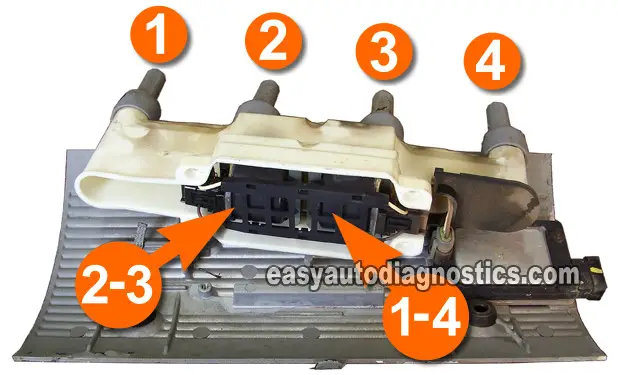

I removed the aluminum cover that contains the ignition housing/ignition coils/ignition module assembly and took it all apart to swap the ignition coils.

To be a more specific, I removed the ignition coils from their places and swapped them. So that the ignition coil that was firing cylinders 1 and 4, was now gonna' fire cylinders 2 and 3. And of course the ignition coil that fired cylinders 2 and 3 was now gonna' fire cylinders 1 and 4.

My objective was to prove once and for all that the ignition coils were or were not the problem. The idea being that if the ignition coil that fed cylinders 1 and 4 was bad (remember that it was cylinder #4 that was misfiring), then by swapping this ignition coil with the ignition coil that fired cylinders 2 and 3, the misfire would now move to a new cylinder.

Well, I put everything back together and started the Grand Am. I redid the cylinder balance test by once again unplugging each fuel injector one at a time, starting with the #4 fuel injector connector and the misfire indeed did move to a new cylinder!

Cylinder #4 had come back to life! When I disconnected the connector for fuel injector #3, the cylinder was dead! The misfire had moved from cylinder #4 to cylinder #3.

This proved to me, beyond a shadow of a doubt, that the ignition coil (for #1 and #4) was bad. I told my boss who called the customer, who agreed to the repair and the problem was solved.

I was not surprised by this result. Even though when I did the initial spark test and all of the ignition coils were firing spark, one of the ignition coils was still bad! These are the problems you and I are faced with that are inherent in this type of ignition system setup.

In Conclusion

Testing the Quad 4 ignition system for a misfire can seem impossible. You can replace every single component (ignition coils, ignition coil cover, spark plug boots, etc.) and still not find the solution to the misfire. Hopefully I've helped to shed some light on the matter and in the process save you some time and maybe some money.

It might seem that I spent an entire day testing this and testing that but in reality, it was all done within an hour.

A lot of folks are under the impression that a technician can just see or hear the symptoms (that the vehicle is experiencing) and without a single physical test, he or she can diagnose the problem. Nothing could be further from the truth. Also, that just connecting a scan tool and reading the codes is all you need to diagnose and repair a car, this is another big/major myth.

As you were able to see/read, a diagnostic is a series of tests. These tests have to start at a logical point and progress from there. And it's only thru' specific tests and the interpreting of their results that you can reach the correct conclusion.

Sometimes it also requires thinking ‘outside the box’ and as you read, the tests can be accomplished with some simple and inexpensive tools (a multimeter, a compression gauge tester, a fuel injector Noid light).

If this info saved the day, buy me a beer!