TEST 2: Making Sure The Blower Motor Speed Switch Is Getting Power

For our second test, we'll check that the blower speed switch is getting 10 to 12 Volts DC.

These 10 to 12 Volts are delivered to the switch by the brown (BRN) wire of the blower switch connector.

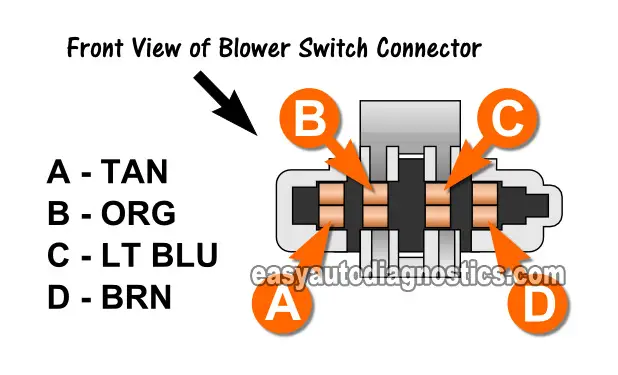

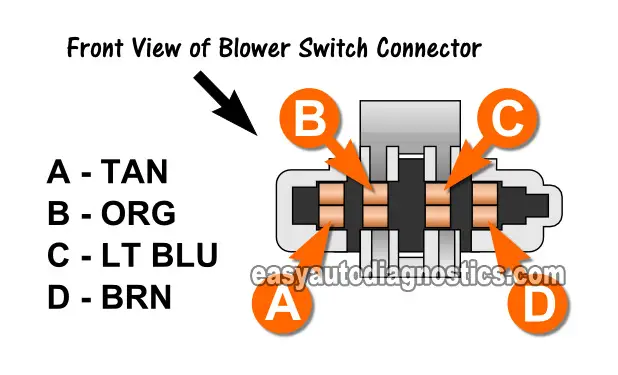

In the illustration of the connector above, the BRN wire connects to the terminal labeled with the letter D.

Let's get started:

- 1

Disconnect the blower motor switch from its connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Turn the AC/Heater Control Panel lever to any position but OFF.

By this I mean place the lever in any of the following positions: MAX AC, NORM AC, BI-LEV AC, VENT, or HTR. - 4

Turn the key to the RUN position but don't crank or start the engine.

- 5

With the red multimeter test lead, probe the D terminal of the blower switch connector.

- 6

Ground the black multimeter test lead on a clean and rust free metal surface on your S10/S15.

I suggest using a jump start cable to Ground the black multimeter test lead to the battery negative (-) terminal (this will ensure a good Ground). - 7

Your multimeter should register 10 to 12 Volts DC if the blower switch is getting power.

Let's examine your test result:

CASE 1: Terminal D has 10 to 12 Volts present. This is the correct and expected test result and tells you that the blower switch is getting battery power.

Let's go to the next test: TEST 3: Using a Jumper Wire To Bypass The Blower Motor Speed Switch.

CASE 2: Terminal D does NOT have 10 to 12 Volts present. This usually means that the fuse that feeds this power is blown or missing.

The fuse that feeds this power to the blower motor switch is the HTR/AC fuse located in the fuse panel under the dash (on the driver's side). Check the fuse and retest.

TEST 3: Using A Jumper Wire To Bypass The Blower Motor Speed Switch

For our final test, we'll use a jumper wire to bypass the blower motor speed switch.

This is a very easy test that will help us do the following:

- Indirectly check the performance of the blower switch.

- Check the circuits between the blower switch connector and the blower motor relay.

IMPORTANT: The jumper wire you use must be of a small enough diameter (gauge) so as not to damage the female metal terminals of the blower speed switch connector. If you use a too thick jumper wire, you may permanently open these terminals up and create an intermittent 'open-circuit' problem.

OK, this is what you need to do:

- 1

Turn the ignition key to the OFF position.

- 2

Disconnect the blower motor switch from its harness connector.

NOTE: All tests in this section are done on the blower switch harness connector and not on the switch itself. The illustration above shows the front view of the female metal terminals of the blower switch connector. - 3

Place the AC/Heater Control Panel lever in any position but OFF (for example: MAX AC, NORM AC, BI-LEV AC, VENT, or HTR).

- 4

Turn the key to the RUN position.

The blower motor should run at LO speed without jumpering any of the terminals of the switch connector.

Turn the ignition key OFF once you've verified the blower motor ran (or did not run). - 5

Jumper terminals D and A together and turn the ignition key to the RUN position (but don't start the engine).

The blower motor should run at M1 speed with terminals D and A jumpered together.

Turn the ignition key OFF once you've verified the blower motor ran (or did not run). - 6

Jumper terminals D and C together and turn the ignition key to the RUN position (but don't start the engine).

The blower motor should run at M2 speed with terminals D and C jumpered together.

Turn the ignition key OFF once you've verified the blower motor ran (or did not run). - 7

Jumper terminals D and B together and turn the ignition key to the RUN position (but don't start the engine).

The blower motor should run at HI speed with terminals D and B jumpered together.

Turn the ignition key OFF once you've verified the blower motor ran (or did not run).

Let's examine your test results:

CASE 1: The blower motor ran when all of the indicated terminals were jumpered together. This tells you several important things:

- That the circuits between the blower motor resistor assembly connector and the blower motor are OK.

- That the blower motor relay is OK.

No further testing is required of the blower motor resistor assembly, the blower relay or the blower motor.

CASE 2: The blower motor DID NOT run when the HI circuit was jumpered but circuits LO, M1, and M2 produced the indicated test result. This usually tells you that the blower motor relay is bad.

If the blower speed switch passed the HI circuit continuity test in TEST 1, you can confidently assume that the problem with HI speed IS NOT related to the blower switch.

CASE 3: The blower motor DID NOT run when jumpering circuits LO, M1, and M2 but ran when the HI circuit was jumpered. This usually tells you that the blower motor resistor assembly is fried and needs to be replaced.

The blower motor resistor assembly can be tested to be sure it's good or bad. You can find the tutorial here:

More 2.5L Chevy S10 Pickup, GMC S15 Pickup, And GMC Sonoma Tutorials

You can find a complete list of 2.5L Chevy S10 pickup, GMC S15 pickup, And GMC Sonoma tutorials here:

Here's a sample of the tutorials you'll find in the index:

- How To Test Engine Compression (1985-1993 2.5L Chevrolet S10, GMC S15, GMC Sonoma).

- How To Test For A Blown Head Gasket (1985-1993 2.5L Chevrolet S10, GMC S15, GMC Sonoma).

- How To Test The TPS (1987-1993 2.5L Chevrolet S10, GMC S15, GMC Sonoma).

- How To Test The MAP Sensor (1985-1993 2.5L Chevrolet S10, GMC S15, GMC Sonoma).

If this info saved the day, buy me a beer!