STEP 1: Testing The Ignition System For Spark

I'm going to suggest that you start your engine no-start diagnostic by making sure that all six spark plugs are sparking.

To get the most accurate test result from your ignition system tests, it's critical that that you use a dedicated spark tester. The spark tester I recommend the HEI spark tester.

Using any other method that does not involve a dedicated spark tester, to test for spark, will have you chasing ghosts. Worst of all, you'll end up wasting time and money replacing good parts that don't solve the problem.

NOTE: This is a basic overview of how to test for spark. If you'd like a more detailed tutorial on how to test the ignition system, check out these tutorials:

- How To Test The Ignition Coil Packs (GM 3.1L, 3.4L).

- Testing The Ignition Module and Crank Sensor (GM 3.1L, 3.4L).

Let's get started:

- 1

Disconnect the #2 cylinder spark plug wire from its spark plug.

- 2

Connect the spark tester to the spark plug wire.

- 3

Ground the spark tester. My preferred method is to connect the spark tester to the battery negative (-) post with a battery jump start cable.

- 4

Have your helper crank the engine as you observe the spark tester from a safe distance.

- 5

The spark tester should spark as your helper cranks the engine.

- 6

Repeat this test on the remaining cylinders.

Let's interpret your spark test results:

CASE 1: Spark is present at all 6 spark plug wires. This is the correct and expected test result.

With this test result you can conclude that:

- The 7X crankshaft position sensor is good.

- The camshaft position sensor is good.

- The ignition coil pack is good.

Your next step is to test the fuel pump's pressure. For this test go to: STEP 2: Testing The Fuel Pump's Pressure.

CASE 2: You got NO spark at all 6 spark plug wires. This test result tells you that the engine is not starting due to a lack of spark.

The components that can cause this are:

- A bad crankshaft position sensor.

- A bad camshaft position sensor.

Your next step is to test the 7X crankshaft position sensor. The following tutorial may be of help:

STEP 2: Testing The Fuel Pump's Pressure

Once you have confirmed that all six spark plugs are sparking (and thus confirming that the ignition system is not behind the no-start problem), the next step is to make sure the fuel pump is working.

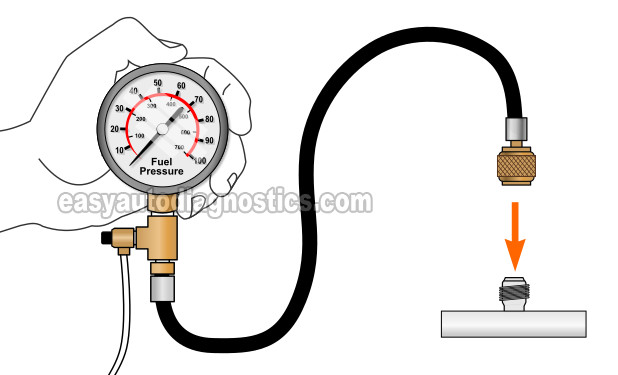

The fuel pump's fuel pressure output can easily be tested with a fuel pressure test gauge.

This fuel pressure test gauge is connected to a Schrader Valve (on the fuel injector rail) to read the fuel pump pressure output.

The fuel pump pressure for the 1995-1999 3.1L Chevrolet Lumina and Monte Carlo is:

- 41-47 PSI Key On With Engine Off.

- With Key On Engine Running, fuel pressure should drop 3 to 10 PSI.

NOTE: If you don't have a fuel pressure tester and need to buy one, take a look at this section: Where To Buy An HEI Spark Tester And A Fuel Pressure Gauge.

You can find a more detailed tutorial on how to test the fuel pump here:

Let's get started:

- 1

Place a shop towel around the Schrader valve. The shop towel's job is to absorb any fuel that may leak when doing step 2.

- 2

Connect the fuel pressure gauge to the Schrader valve on your engine's fuel injector rail.

- 3

When ready, ask your helper to cycle the key ON and OFF but don't crank the engine while you observe the fuel pressure tester's gauge.

Check the connection at the Schrader valve for fuel leaks and if any tighten the gauge a bit more (by hand only) to eliminate them. - 4

Crank the engine and check the fuel pressure gauge. Your fuel pressure gauge should register the specified fuel pressure.

Let's take a look at your fuel pressure test results:

CASE 1: The fuel pressure test gauge registered 0 PSI. This confirms that the no-start problem is caused by a lack of fuel.

This usually means that the fuel pump is bad and needs to be replaced.

CASE 2: The fuel pressure gauge registered the indicated fuel pressure specification. This fuel pressure gauge result lets you know that the fuel pump is working and delivering enough fuel to the fuel injectors. You can conclude the fuel pump is OK and not behind the no-start problem.

The next step is to check for a blown head gasket. Go to: STEP 3: Checking For A Blown Head Gasket.

CASE 3: The fuel pressure is lower than the indicated PSI. This tells you that the fuel pump is defective.