TPS TEST 2: Testing The 5 Volt Reference Signal

The throttle position sensor (TPS) on your 3.8L V6 Buick (or Chevy, Olds, Pontiac) needs power to work.

This power comes in the form of 5 Volts DC from the fuel injection computer.

The wire that delivers these 5 Volts to the TPS is the grey wire of the TPS connector.

This test will help you to confirm if these 5 Volts are present or not. This is what you'll need to do:

- 1

Grab your multimeter and select Volts DC mode on it.

- 2

Probe the gray wire, with the red multimeter test lead and an appropriate tool (like a wire-piercing probe).

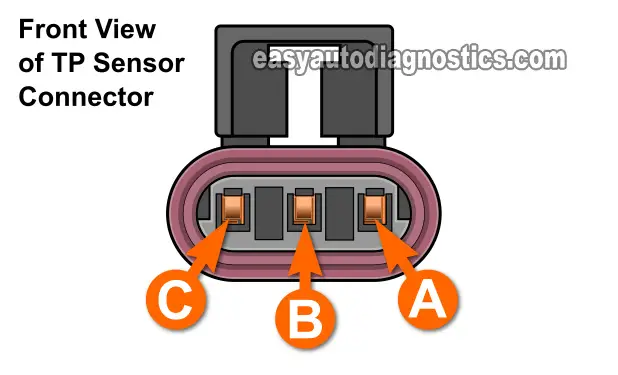

The grey wire connects to the terminal labeled with the letter C (in the illustration above).

If you probe the front of the connector, be careful not to damage the female terminal. - 3

Connect the black multimeter test lead to the negative (-) battery terminal.

- 4

When everything is set up, have your helper rotate the key to its ON position but don't start the engine.

- 5

The multimeter should display 4.5 to 5 Volts.

Let's take a look at what your test results mean:

CASE 1: The multimeter registered 4.5 to 5 Volts. This test result confirms that the fuel injection computer and the circuit is supplying the TPS with power.

The next step is to test the Ground circuit of the throttle position sensor, go to: TEST 3: Ground Circuit Test.

CASE 2: The multimeter DID NOT register 4.5 to 5 Volts. Then the computer or the circuit are NOT providing the voltage that the TPS needs to operate.

The two most likely reasons for this are: 1) an open-circuit problem in the circuit or 2) the PCM may be fried. Altho' it's beyond the scope of this article to test these two conditions, you have now eliminated the throttle position sensor (TPS) on your 3.8L V6 Buick (or Chevy, Olds, Pontiac) as being the cause of the problem and/or the TPS Diagnostic Trouble Code (DTC) lighting up the check engine light (CEL).

TPS TEST 3: Ground Circuit Test

So far you have verified that the TPS is not creating a throttle position signal (TPS TEST 1) and that the TPS is getting power (TPS TEST 2).

The second step, before condemning the throttle position sensor, is to verify that it also has a good Ground.

The PCM is the one that provides this Ground internally, so be careful and don't accidentally or intentionally apply power (12 Volts) to this circuit or you'll fry the PCM.

OK, here are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

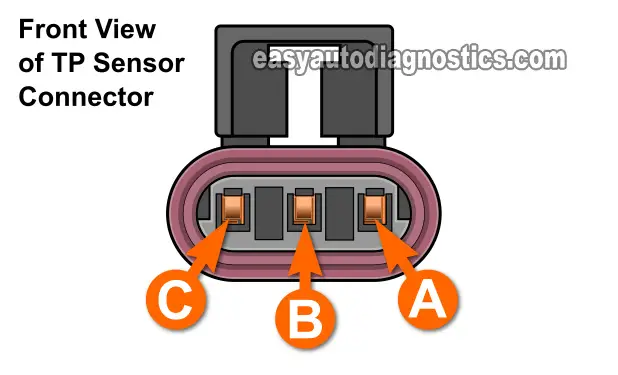

Probe the black wire, with the black multimeter test lead and an appropriate tool.

The black wire connects to the terminal labeled with the letter A (in the illustration above).

If you probe the front of the connector, be careful not to damage the female terminal. - 3

Connect the red multimeter test lead to the positive (+) battery terminal.

- 4

Have your helper rotate the key to its ON position but don't start the engine.

- 5

The multimeter should display 10 to 12 Volts.

Let's take a look at your test results:

CASE 1: The multimeter showed 10 to 12 Volts. This is the correct test result and confirms the PCM and the wire/circuit (that supply this Ground) are OK.

This multimeter test result also confirms that the TPS sensor is bad and needs replacement if you have:

- Confirmed the TPS is not producing a signal that increases/decreases as you open/close the throttle plate (TEST 1).

- Confirmed the TPS is getting power (TEST 2).

- In this test section, confirmed the TPS is receiving Ground.

CASE 2: The multimeter DID NOT show 10 to 12 Volts. This test result tells you that the TPS is not receiving Ground. Without Ground, the TPS will not function.

A lack of Ground usually indicates a problem with either the PCM (internal fault/problem) or an open in the wire between the TPS and the PCM itself.

Altho' testing these two conditions are beyond the scope of this article, you have now eliminated the throttle position sensor (TPS) on your 3.8L V6 Buick (or Chevy, Olds, Pontiac) as being the cause of the problem and/or the TPS diagnostic trouble code (DTC) lighting up the check engine light (CEL).

TPS Code Won't Go Away

So you've tested the throttle position sensor (TPS) and according to the test results, the TPS is good. But the check engine light keeps coming back on even after you erased the diagnostic trouble code (DTC) from the computer's (PCM) memory. Well, here are a couple of suggestions that might inspire your next diagnostic move:

- The throttle plate's idle-stop screw's factory adjustment has been altered so that the engine could be idled up and mask a miss/misfire and/or rough idle. This increases the TP sensor's signal to the PCM. The PCM doesn't like it and lights up the check engine light (CEL).

- The throttle cable is binding and causing the throttle plate to not fully close.

- This can be verified by simply having someone inside the vehicle pushing the accelerator cable to the floor and releasing it, with the engine OFF, while you visually check that the throttle plate and cable are not getting stuck somewhere in their travel.

- The TPS is failing intermittently. Which means that it works fine most of the time, but every now and then it doesn't:

- I have found that the best way to test these intermittent problems is to road-test the vehicle with the multimeter hooked up to the TP signal wire with a long wire so that I can comfortably observe the signal going up and down as I or someone else drives.

- The TP sensor's connector is bad, usually the locking tab is broken and the connector has worked itself loose, causing an intermittent false connection.

How To Calibrate The 1988-1992 TPS

Vehicles equipped with a throttle position sensors for year models 1988 through 1992 have an adjustable sensor that has to be calibrated (if replaced with a new one).

This type of TPS is located under the throttle body and the throttle body usually has to be removed to gain access to it, therefore, the TPS adjustment has to be done before you re-install the throttle body:

This is what you'll need to do:

- 1

Install the new TP sensor and connect it to its electrical connector -but do not tighten the two screws.

- 2

Turn the key to the ON position but don't start the engine.

- 3

Place your multimeter in Volts DC mode.

If you disconnected the battery negative (-) terminal to replace the TP sensor, reconnect the battery. - 4

Connect the red multimeter test lead to the signal wire of the TPS.

This is the middle wire in the connector. - 5

Connect the black multimeter test lead to the battery negative (-) post.

- 6

With the throttle plate closed, adjust the TP sensor till your multimeter reads between 0.38 and 0.42 Volts DC.

- 7

Tighten the two TP sensor screws once the TPS voltage output is between 0.38 and 0.42 Volts DC. The sensor is now calibrated.

- 8

Re-install the throttle body.

Use a new gasket on the throttle body. Also, don't use any type of gasket sealer or sealant (RTV Silicone) on the gasket since this will later create a vacuum leak. - 9

Before starting the vehicle, disconnect the battery for at least one full minute.

This will reset the closed throttle value, inside the PCM, back to 0.

And you're done!

If this info saved the day, buy me a beer!