TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts

If you've reached this test section, then you've confirmed that the MAP sensor's voltage signal is stuck in one value (however small or big) as you applied/released vacuum to the sensor.

In this test section, we're gonna' make sure that the MAP sensor is getting 4.5 to 5 Volts DC from your vehicle's fuel injection computer.

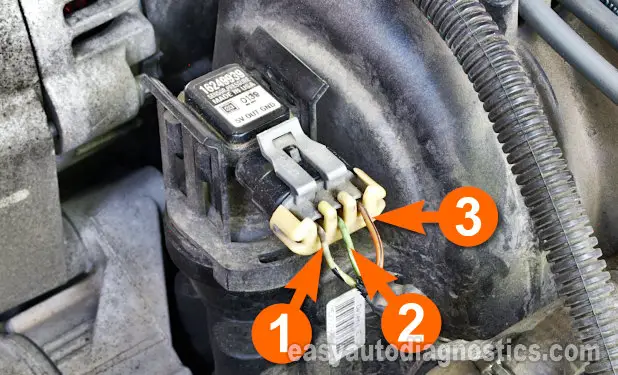

The wire that supplies 5 Volts to the MAP sensor is the grey (GRY) wire labeled with the number 1 in the photo above.

These are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

Disconnect the MAP sensor from its electrical connector.

- 3

Gently probe the terminal that connects to the grey (GRY) wire with the red multimeter test lead.

NOTE: Be careful and don't damage the female terminal. I recommend using a back probe on the connector or a wire piercing probe on the wire. - 4

Connect the black multimeter test lead to the negative (-) battery terminal.

- 5

Have a helper turn the key on but don't start the engine.

- 6

The multimeter should display 4.5 to 5 Volts on its screen.

Let's examine your test result:

CASE 1: The multimeter registered 4.5 to 5 Volts. This is the correct test result.

Now that you have confirmed that the MAP sensor is getting power. the next step is to make sure that it is getting Ground. For this test go to: TEST 3: Making Sure The MAP Sensor Is Getting Ground.

CASE 2: The multimeter DID NOT register 4.5 to 5 Volts. Without these 5 Volts the manifold absolute pressure sensor will not function.

The two most likely reasons for this are:

- An open-circuit problem in the 5 Volt supply wire between the connector and the fuel injection computer.

- The fuel injection computer may be fried internally (very rare).

Altho' it's beyond the scope of this tutorial to test these two conditions, you have now eliminated the manifold absolute pressure (MAP) sensor itself as being the cause of the problem and/or the MAP sensor diagnostic trouble code (DTC) lighting up the check engine light (CEL).

TEST 3: Making Sure The MAP Sensor Is Getting Ground

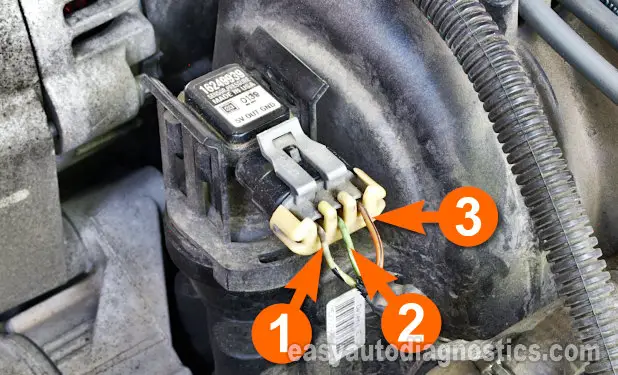

The wire that supplies Ground to the MAP sensor is the wire labeled with the number 3 in the photo above.

Depending on your specific vehicle, this wire may a black (BLK) wire or an orange with black stripe (ORG/BLK) wire.

To check for the presence of Ground, we'll do a simple multimeter voltage test.

IMPORTANT: If you probe the front of the female terminal, probe it very gently with your multimeter test leads. Or you run the risk of damaging the terminal.

CAUTION: The fuel injection computer provides Ground for the MAP sensor. Be careful and don't short the wire to battery 12 Volts or you'll fry the computer. The multimeter voltage test I'm suggesting is a safe way to test for Ground in this wire.

Let's get testing:

- 1

Place your multimeter in Volts DC mode.

- 2

Disconnect the MAP sensor from its electrical connector.

- 3

Gently probe the female terminal that connects to the wire labeled number 3 in the photo above with the black multimeter test lead.

NOTE: Be careful and don't damage the female terminal. I recommend using a back probe on the connector or a wire piercing probe on the wire. - 4

Connect the red multimeter test lead to the battery positive (+) terminal.

- 5

Have your helper turn the key on but don't start the engine.

- 6

Your multimeter should display 10 to 12 Volts if Ground is present.

Let's examine your test result:

CASE 1: The multimeter showed 10 to 12 Volts. This test result tells you that Ground is present in the wire.

You can correctly conclude that the MAP sensor is bad and needs to be replaced if you have confirmed:

- That the MAP sensor voltage signal does not decrease when you apply vacuum to the MAP sensor (TEST 1).

- That the MAP sensor is receiving 5 Volts DC (TEST 2).

- That the MAP sensor is receiving Ground (in this test section).

CASE 2: The multimeter DID NOT show 10 to 12 Volts. This test result indicates a problem with either the PCM (internal fault/problem) or an open in the wire between the MAP sensor and the PCM itself.

Altho' testing these two conditions are beyond the scope of this tutorial, you have now eliminated the MAP sensor as being the cause of the problem and/or the MAP sensor diagnostic trouble code (DTC) lighting up the check engine light (CEL).

MAP Sensor Code Won't Go Away

Quite a few things can trick the fuel injection computer into thinking that the MAP sensor is bad when it isn't.

So, if you've already replaced the MAP sensor but the MAP sensor trouble code keeps coming back, then this section might help.

This type of problem generally occurs when the MAP sensor senses and reports an erratic vacuum pressure that is being caused by some sort of engine mechanical problem or a lack of fuel pressure.

Here are a few suggestions on what to check (if this is what's happening in your specific situation):

- Check the MAP sensor's O-ring. There's a good chance that the o-ring on the MAP sensor's vacuum inlet nipple (the part that goes into the intake manifold to sense the vacuum) is torn, missing or distorted. When this happens, ambient air will leak into the intake manifold and skew the MAP sensor's readings.

- Check engine compression. Worn or damaged cylinder head valves or piston rings will cause the engine to produce erratic and low vacuum readings that can fool the fuel injection computer into thinking the MAP sensor is bad.

- The MAP sensor is failing intermittently. Which means that it works fine most of the time, but every now and then it doesn't:

- I have found that the best way to test these intermittent failures is to slightly tap the MAP sensor with the handle of a screw-driver and see if this tapping screws up the voltage readings as I apply vacuum.

- Check the MAP sensor's connector. See if the MAP sensor connector is broken (this could be causing an intermittent open-circuit or short-circuit problem in the MAP signal wire). This usually happens when the MAP sensor's electrical connector's locking tab has broken.

- Check the fuel pump's pressure with a fuel pressure test gauge. The second most common cause of a MAP sensor code is a lean air/fuel mixture caused by a failing fuel pump. Most of the time a fuel pump will fail completely and the engine won't start, but not always. The fuel pump can slowly fail and not send enough fuel to keep the engine humming along nicely. To check for this, I recommend a fuel pressure test.

More 3.8L V6 GM Tutorials

You can find a complete list of 3.8L GM V6 tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The MAF Sensor (GM 3.8L V6 1996-2005).

- How To Test A Does Not Crank Condition -Case Study (GM 3.8L).

- GM 3.8L Ignition Control Module And Crank (3X, 18X) Sensor Test.

- How To Test The Ignition Coil Pack -Misfire Troubleshooting Tests (GM 3.8L).

If this info saved the day, buy me a beer!