TEST 2: 5 Volt Reference Circuit Test

The second thing we need to do now, is to make sure that Throttle Position (TP) Sensor 1 is getting power. This power is in the form of 5 Volts DC and is provided by the Throttle Actuator Control (TAC) Module.

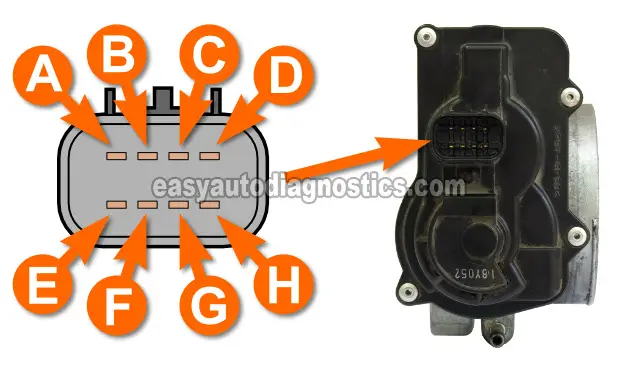

The wire that you'll be testing is the gray wire labeled with the letter H in the photo below.

Alright, this is what you need to do:

- Place your multimeter in Volts DC mode.

- With the red multimeter test lead, probe the wire identified with the letter H in the photo below.

- This is the Gray colored wire of the connector.

- Ground the black multimeter test lead directly on the battery negative (-) terminal.

- Have a helper turn the key ON, but don't crank or start the engine.

- If all is OK, your multimeter should register about 5 Volts.

- Let's interpret your test results below:

Let's take a look at what your test results mean:

CASE 1: Your multimeter registered 5 Volts. So far so good, since this test result lets you know that Throttle Position Sensor 1 is getting power.

The next step is to check that Throttle Position (TP) Sensor 1 is getting Ground. Go to: TEST 3: Reference Low (Ground) Circuit Test.

CASE 2: Your multimeter DID NOT register 5 Volts. Double check your connections and make sure you're testing the correct wire.

If your multimeter still does not register 5 Volts in this circuit, then you've found the cause of the P0120 diagnostic trouble code (DTC). Repair the issue causing these missing 5 Volts, since without power TP Sensor 1 won't function.

Now, although it's beyond the scope of this tutorial to troubleshoot these missing 5 Volts, here are the two most like causes:

- There's an ‘open-circuit’ problem on this wire between the electronic throttle body's connector and the Throttle Actuator Control (TAC) Module.

- The Throttle Actuator Control (TAC) Module is bad.

TEST 3: Reference Low (Ground) Circuit Test

Now, we're gonna' test the Ground circuit (also know in GM tech terms as the Reference Low Circuit).

This Ground, like the 5 Volts you tested in the previous test, is provided by the Throttle Actuator Control (TAC) Module. This means that you need to be careful to NOT short this circuit to 12 Volts intentionally or accidentally or you're gonna' fry the TAC Module.

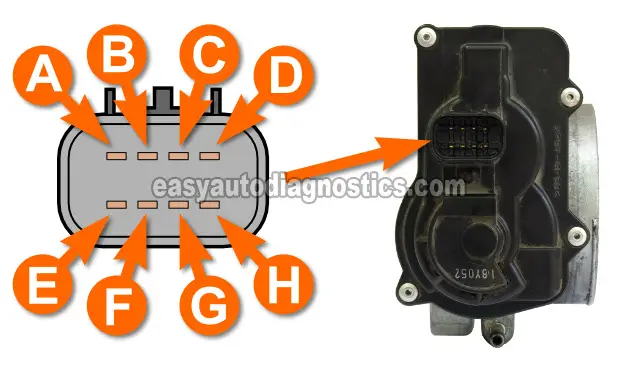

The wire that you'll be testing is the Black wire labeled with the letter D in the photo below.

Alright, this is what you need to do:

- Place your multimeter in Volts DC mode.

- With the black multimeter test lead, probe the wire identified with the letter D in the photo below.

- This is the Black colored wire of the connector.

- Ground the red multimeter test lead directly on the battery's positive (+) terminal.

- Have a helper turn the key ON, but don't crank or start the engine.

- If all is OK, your multimeter should register 10 to 12 Volts.

- Let's interpret your test results below:

CASE 1: Your multimeter registered 10 to 12 Volts. So far so good, since this test result lets you know that the Throttle Actuator Control (TAC) Module is providing Ground to TP Sensor 1.

The next step is to check that Throttle Position (TP) Sensor 1 is creating the correct TP Signal. Go to: TEST 4: Testing The TP Signal Circuit.

CASE 2: Your multimeter DID NOT register 10 to 12 Volts. Double check your connections and make sure you're testing the correct wire.

If your multimeter still does not register 10 to 12 Volts in this circuit, then you've found the cause of the P0120 diagnostic trouble code (DTC). Repairing the cause of this missing Ground will get TP Sensor 1 back to work, since without Ground, TP Sensor 1 won't work.

Now, although it's beyond the scope of this tutorial to troubleshoot the problem with this Ground, but here are the two most like causes:

- There's an ‘open-circuit’ problem on this wire between the electronic throttle body's connector and the Throttle Actuator Control (TAC) Module.

- The Throttle Actuator Control (TAC) Module is bad.

TEST 4: Testing The TP Signal Circuit

OK, so far you've tested and confirmed the presence of power (5 Volts) and Ground. What we need to do now, is to check the voltage output of Throttle Position (TP) Sensor 1.

Specifically, what you need to do is confirm that TP Sensor 1 voltage signal is not less than 0.37 Volts DC or not more than 4.51 Volts DC with the Key On and Engine Off (KOEO).

The average voltage I have observed, in this circuit with the Key On and Engine Off (KOEO), has been: 1.16 Volts.

OK, to get this pot boiling, this is what you need to do:

- Turn the key ON but don't crank or start the engine.

- Set your multimeter in Volts DC mode.

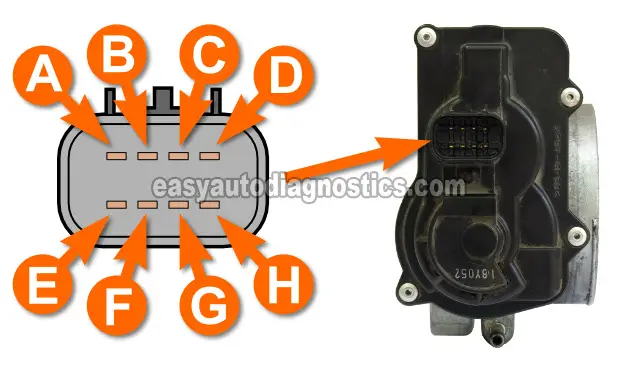

- With the throttle body connected to its connector, probe the Dark Green wire.

- This is the wire identified with the letter G in the photo of the connector above.

- This is where a wire piercing probe comes in handy since it'll let you easily access the wire inside the insulation (to see what this tool looks like, click here: Wire Piercing Tool).

- Ground the multimeter's black lead directly on the battery negative (-) terminal.

- Observe your multimeter's voltage DC reading.

- You should see about 1.6 Volts DC.

- To be more specific, if everything is OK, your multimeter SHOULD NOT register a voltage less than 0.37 Volts or more than 4.51 Volts DC.

Let's analyze your test result:

CASE 1: Your multimeter registered about 1.6 Volts DC. To be a bit more specific, your multimeter DID NOT register a voltage less than 0.37 Volts or more than 4.51 Volts DC.

OK, so far so good, the next step is to resistance test the Throttle Position (TP) Sensor 1 inside the throttle body with your multimeter in Ohms mode. Go to: TEST 5: Throttle Position (TP) Sensor 1 Resistance Test.

Here's why: Even tho' your test results indicate the correct average TP Signal voltage, there's a good chance that it could still be bad. So, to make sure, we'll check TP Sensor 1 along its entire opening and closing range with your multimeter in Ohms mode.

CASE 2: Your multimeter DID NOT register the indicated voltage. This is not good. The next test is to do a resistance test of TP Sensor 1.

This test will tell you if TP Sensor 1 is good or bad, go to: TEST 5: Throttle Position (TP) Sensor 1 Resistance Test.