Interpreting Your Compression Test Results

If your compression test results have confirmed that one or several cylinders are producing a low compression value (compared to the rest), this test section will help you find out if they're causing and problem or not.

Within a certain range, a variation in the compression values will not cause any problems. But if the variation is greater than 15%, your Chevrolet S10 or GMC Sonoma's 4.3L V6 engine will suffer a rough idle condition or a misfire problem.

You can calculate this 15% difference in one of two ways:

- Do the math with pen and paper.

- Use my low compression calculator.

If you want to use the low compression calculator, go here: Online Low Engine Compression Calculator.

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that I got the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 160 PSI |

| #6 | 155 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

TEST 2: Wet Engine Compression Test

A low or 0 PSI compression value is the end result of one of the following conditions:

- The affected cylinder's piston rings are worn out.

- The affected cylinder's intake/exhaust valves are worn or damaged.

Thankfully, at this stage, you don't need to tear the engine apart to find out the root cause of the low compression value since a wet compression test will suffice to pinpoint the source.

Let's get started:

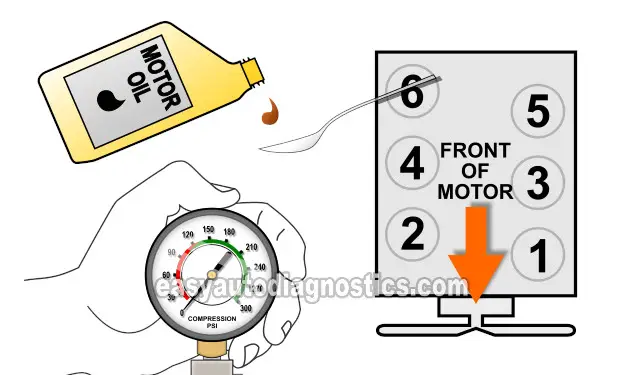

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the ‘dry’ compression test.

You don't have to add a lot of oil. The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder.

Do not use any type of tool to tighten the compression tester. Hand tight is fine. - 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's take a look at what your test results mean:

CASE 1: The compression value shot up. This test result confirms that the piston compression rings are worn out and causing the low compression value you got for this cylinder in TEST 1.

CASE 2: The compression value stayed the same. This test result confirms that the low compression problem of the affected cylinder is due to worn or damaged cylinder head valves.

If this info saved the day, buy me a beer!