Testing The Shift Solenoid With A Multimeter

To access shift solenoid A or B you'll need to remove the transmission fluid pan. There are certain precautions you need to take before removing it, so take a look at this section: Before You Remove The Transmission Oil Pan.

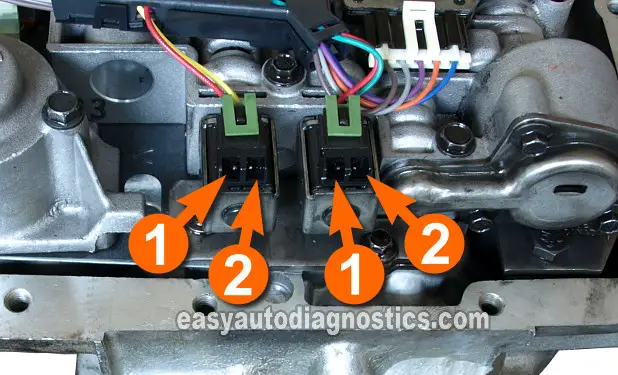

Both shift solenoids A and B are located toward the rear of the transmission (see photo 2 of 2 in the image viewer) and you don't need to remove them to test them.

OK, these are the test steps:

- 1

Remove the transmission oil pan.

- 2

Place your multimeter in Ohms (Ω) mode.

- 3

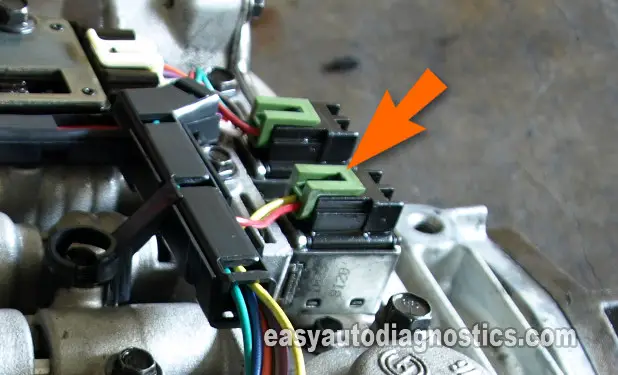

Disconnect the electrical connector of both shift solenoids. Be very gentle in disconnecting them, cause the connector's locking tab breaks very easily.

If the locking tab breaks, take a look at: The Shift Solenoid Connector's Locking Tab Broke. - 4

Once disconnected, measure the resistance of each one by probing the exposed soldered terminals of the solenoids (as identified with the numbers 1 and 2 for shift solenoid B and numbers 1 and 2 for shift solenoid A). See photos 1 and 2 in the image viewer.

NOTE:You do not need to remove the shift solenoids to test them (but you can if you want). - 5

At 68° F (20° C) you should see 19 to 24 Ω.

These are the normal values you should see with the engine completely cold (even if the engine's temperature is not at 68° F).

At 212° F (100° C) you'll see 24 to 31 Ω (this means you're testing them with a hot engine and I don't recommend this for safety reasons).

NOTE: If this temperature business sounds confusing to you, let me say that no matter what the temperature of the transmission, you should see a value between 19 to 31 Ωs (if the solenoid is OK).

Let's interpret your test results:

CASE 1: The multimeter registered the indicated Ohms values. This is the correct and expected test result and it tells you that the shift solenoids are OK and are not causing the transmission shift issue.

CASE 2: The multimeter DID NOT register the indicated Ohms values. Repeat the test.

If the shift solenoid still does not come within the indicated resistance specification, then this test result confirms that it's bad. Replace the shift solenoid.

Both of these shift solenoids are held in place by a metal locking pin, that you'll need to pry out using a small pick or a small flat tipped screwdriver to remove them.

One of the shift solenoids may have a valve under spring pressure that may pop out when you remove the shift solenoid. So be prepared to catch it if does pop out, since this valve can not hit the floor.

Both shift solenoids A and B are the exact same part. My suggestion to you is that if one is bad, replace them both, since they're not expensive and the other one will eventually fail too. To find out where to buy the shift solenoids, see the section: Where To Buy The Shift Solenoids.

The Shift Solenoid Connector's Locking Tab Broke

The plastic locking tab of the shift solenoid's connector becomes brittle over time, so there's a good chance that it'll break when you disconnect it from the solenoid.

This is a very common problem and if it happens to you, you'll need to replace the internal transmission electrical harness.

The internal transmission wiring harness is generally a component that you'll have to order online and receive by mail.

Since you may need your vehicle back on the road ASAP, having to wait a few days for it can be a bummer. So, if you do break a locking tab, don't freak out.

I've been in this situation many times and I've had no choice but to re-use the same wiring harness (temporarily) with no ill-effects (in the short term).

If this happens to you, simply reconnect the connector (even tho' the locking tab is broken) without using any type of sealant or glues and wait for the wiring harness to arrive by mail.

Once the wiring harness arrives, install it to make sure that this repair doesn't come back.

You can find them and buy them here:

|

|

|

| Fits all GM 4L60-E 1996-2002. Same as AC Delco 24241215 |

| Fits all GM 4L60-E 1996-2002 |

| Fits all GM 4L65-E 1993-2007 |