PART 2: Checking The Fuel Injector Spray Pattern

If you've made it to this point, you've already checked the 'dead' cylinder's fuel injector's internal resistance and confirmed it matches the other 3 'live' fuel injectors.

With an internal electrical issue ruled out, the next step is to remove the 'dead' cylinder's injector.

After it's off the fuel injector rail, we'll test its spray pattern using a DIY fuel injector cleaning tool (available online) along with a can of brake cleaner

This fuel injector cleaning tool kit includes two important components:

- A 12 Volt power module that triggers the fuel injector in pulses, similar to how the fuel injection computer does it.

- An adapter that connects the fuel injector to a spray can of brake cleaner.

After setting up the test, a good fuel injector should spray the brake cleaner in a fine mist. If the injector is clogged or faulty, it will either squirt the cleaner or not spray at all.

The cool thing about this fuel injector cleaner took kit is that it's not expensive. You can purchase it here:

- QX Fuel Injector Tester & Adapter for Diagnosis and Cleaning of Injectors DIY Cleaning Tool Kit (at: amazon.com).

- EM276SET Fuel Injector Tester & Adapter DIY Cleaning Tool Kit Set (at: amazon.com).

IMPORTANT: Before installing the same or new fuel injector back on the fuel injector rail, take a look at: Important Tips For Installing A Fuel Injector.

CAUTION: Use safety glasses when performing the fuel injector cleaning procedure.

Alright, these are the test steps:

- 1

Remove the fuel injector.

- 2

Connect the fuel injector to the plastic adapter.

NOTE: I've found that securing the fuel injector to the adapter with a thick rubber band helps to make the whole process easier and less messier. - 3

Connect the fuel injector to the tool's power module.

NOTE: Follow the tool's safety and recommended set-up instructions. - 4

Connect the cleaning kit's power module to your CR-V's battery.

- 5

Connect the fuel injector/adapter to a spray can of brake cleaner and press them onto the spray can.

- 6

Activate the power module.

- 7

The fuel injector should spray fuel in a fine mist and in a conical shape.

Let's interpret your test result:

CASE 1: The fuel injector did not spray at all. This tells you that the fuel injector is bad and needs to be replaced.

CASE 2: The fuel injector sprayed the brake cleaner in a fine mist and in a conical pattern. This tells you that the fuel injector is OK.

CASE 3: The fuel injector sprayed the brake cleaner in a squirt or a stream (not in a fine mist). This tells you that the fuel injector is dirty/clogged.

Continue cleaning the fuel injector until it starts to spray in a fine mist. If the cleaning it doesn't restore the injector's spray pattern to that of a fine mist, you'll need to replace it.

Important Tips For Installing A Fuel Injector

When installing a fuel injector (whether it's a new one or the same one) on the fuel injector rail, it's important to follow these important tips:

- Use new fuel injector O-rings: Always replace the O-rings when installing a fuel injector, whether it's a new injector or the same one going back in.

New injectors typically come with new O-rings, but if you're reusing the same injector, you have to purchase new ones. New O-rings are critical for a proper seal, helping prevent both fuel and vacuum leaks. - Lubricate the O-rings: Before fitting the new O-rings onto the injector, apply a thin layer of clean engine oil (5W-30 or lighter). Avoid using silicone-based greases or other lubricants.

Applying a light coat of engine oil to the O-rings helps prevent damage when inserting the fuel injector into both the injector rail and the intake manifold port. Without this lubrication, the O-rings can get damaged during installation, leading to fuel or vacuum leaks when you start the engine. - Replace damaged connectors: If the fuel injector's connector is damaged, replace it with a new one.

- Avoid butt connectors: If you need to replace a fuel injector connector, avoid using butt connectors to join the new connector's wires to the engine wiring harness. Instead, solder the wires for a permanent repair. Butt connectors are notorious for eventually losing their grip on the wires, leading to intermittent contact issues.

Remember, the goal is to prevent gasoline leaks and avoid the risk of fire. Take your time to ensure everything is properly seated and secure.

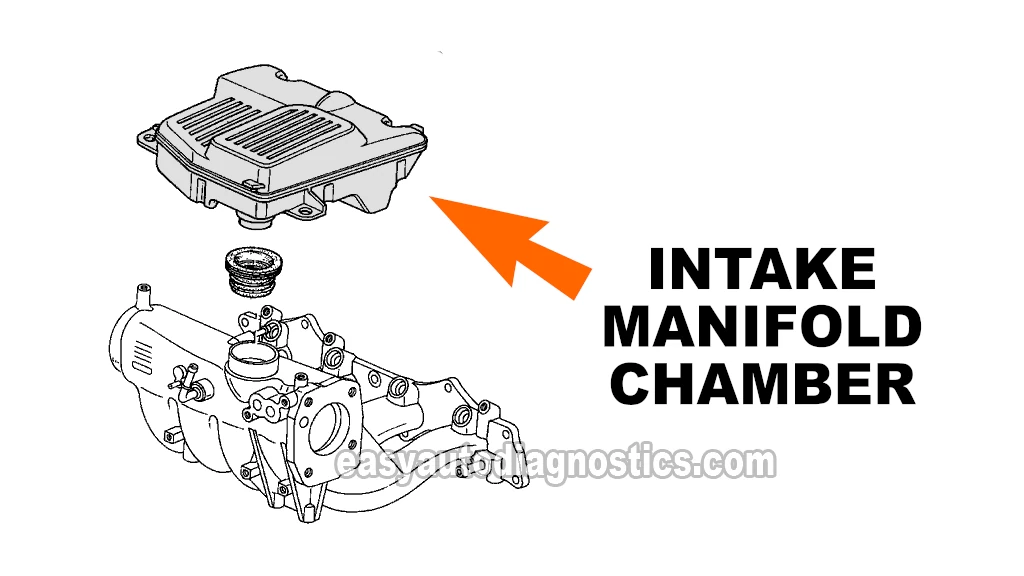

Precautions To Take When Removing The Intake Manifold Chamber

Before and during the intake manifold's chamber removal, keep the following important tips in mind:

- Keep a repair manual on hand: Grab a repair manual (preferably a Haynes Manual, as Chilton manuals tend to be less reliable) to get detailed instructions on the intake manifold chamber removal process, along with torque specs for the bolts.

- Disconnect the battery: Disconnect the negative (-) battery cable before removing the intake manifold chamber, and keep it disconnected throughout the injector testing process.

- Prevent debris from entering intake manifold port: To keep foreign objects like bolts, nuts, or metal parts from falling into the intake manifold after removing the chamber, cover its exposed port with a clean rag or rags.

- Organize removed parts: As you take off bolts, nuts, and other components from the intake chamber, place them in a container and keep it clear of the engine bay.

- Don't crank the engine: Never attempt to crank the engine with the chamber removed from the intake manifold.

If anything falls into the intake manifold without you noticing and you start the engine, you're in for a serious headache! You'll probably have to remove the cylinder head to retrieve the part that fell in. So stay alert and be careful.

Removing the chamber isn't rocket science; plenty of people do it without any issues. The trick is to take a few simple precautions to avoid unnecessary problems.

More 2.0L Honda CR-V Diagnostic Tutorials

You can find a complete list of 2.0L Honda CR-V tutorials and wiring diagrams in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test Engine Compression (1997-2001 2.0L Honda).

- How To Test Misfire Trouble Codes (1997-2001 2.0L Honda CR-V).

- P0420 -What Does It Mean? (1997-2001 2.0L Honda CR-V).

- How To Test The Fuel Pump (1997-2001 2.0L Honda CR-V).

If this info saved the day, buy me a beer!