Testing The Fuel Pump

As I mentioned earlier, you'll need a fuel pressure gauge for this part. Depending on the type of vehicle you have, you'll be able to buy an inexpensive one or you'll have to buy a more costly one with the fittings you'll need to tap into the fuel system.

You'll have to look at the vehicle's repair manual to find out how to connect your gauge but the basic layout is as follows for domestic and import cars and trucks:

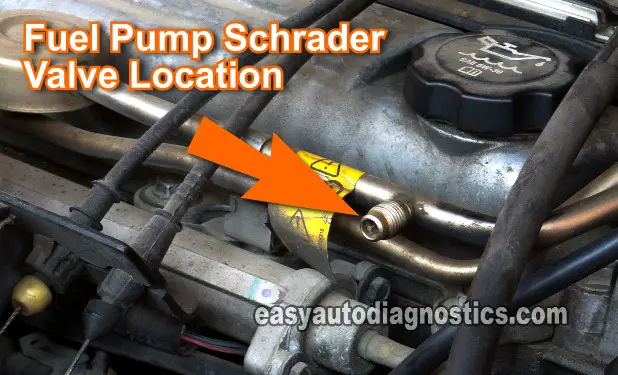

- Most but not all of the domestic vehicles have a Schrader valve on the fuel injector rail on which to connect the fuel pressure gauge.

- On others, you have to insert a special fitting/adapter between the fuel injector rail and the pressure line.

- The majority of the imports you have to remove a banjo-type bolt from the fuel filter or fuel injector rail and insert a special fitting in its place to connect the gauge.

- Or disconnect the rubber inlet fuel hose at the fuel injector rail to install a T-type fitting to which to connect the gauge. This is true of mid 90's and older cars.

Important! Since you'll be working around gasoline and a cranking engine, use common sense and above all take all necessary safety precautions to keep from setting the vehicle or yourself on fire.

Having said that, after connecting the fuel pressure gauge, have an assistant crank up the vehicle. As with the spark test, the results of this test are few. You'll get one of two results:

- No fuel pressure reading on the gauge.

- A fuel pressure reading.

- This pressure reading may be lower than what the specification calls for.

- This pressure reading will be the correct pressure called for in the specifications section of your repair manual.

No Fuel Pressure

OK, getting a no-pressure reading on the gauge is not enough to condemn the fuel pump. The most likely cause is probably a bad fuel pump, but not always. There are a few factors that could cause the fuel pump not to work for example:

- If its a Ford/Lincoln/Mercury vehicle, the fuel pump inertia switch has been triggered and may need to be reset.

- The fuel pump relay is defective.

- The fuel pump fuse is blown.

- On cars such as Chrysler/Dodge models, the crankshaft position sensor is not working.

- In these cars and trucks, if the ECM (Fuel Injection Computer) doesn't see this sensor's signal, it won't activate the fuel pump relay.

- Not only that, you won't have power to the ignition coil(s) for spark.

The next logical step is to probe the circuit that supplies power to the fuel pump with a test light or a multimeter and crank the vehicle. You'll need a repair manual for the circuit descriptions.

With this test you're testing to see if the fuel pump is receiving power. If the fuel pump is receiving juice, then you can replace the fuel pump with the confidence that it'll solve the problem.

Most technicians take one more step after verifying that there's no power going to the fuel pump. And this is to feed it 12 Volts with a fused jumper wire or a Power Probe (the Power Probe is another very handy tool) Why?

Well, there's a good possibility that the fuel pump is good and some other component sharing the power circuit blew the fuse. By applying battery voltage to the pump, he eliminates this possibility. If the fuel pump is good, it should put out the specified pressure and the technician can see it on the fuel pressure gauge.

Fuel Pressure

If you do get a fuel pressure reading, you've got to verify it's the correct one by checking online or in a repair manual.

After comparing the fuel pressure reading on the gauge to the specification and you find that its lower than specified, then the fuel pump is bad.