TEST 1: Inducing A Rich Condition

The first thing we'll do, is to see how fast the oxygen sensor responds to a Rich condition (that you will induce yourself).

This can easily be done by spraying a little carburetor cleaner into the engine while it's running.

Since your vehicle is equipped with a mass air flow sensor, you should not disconnect the air duct between it and the Throttle to spray carb cleaner into it (since this will cause the engine to stall).

My recommendation is to spray carb. cleaner into a vacuum hose, that has vacuum when the engine is idling.

Once the carb spray hits the engine cylinders, you'll get an instant Rich condition which will make the O2 sensor respond by producing its maximum voltage (0.900 Volts +) and you'll be able to see this on your scan tool (in Live Data mode).

Alright, this is what you'll need to do:

- 1

Connect your scan tool to your car and get to its Live Data mode.

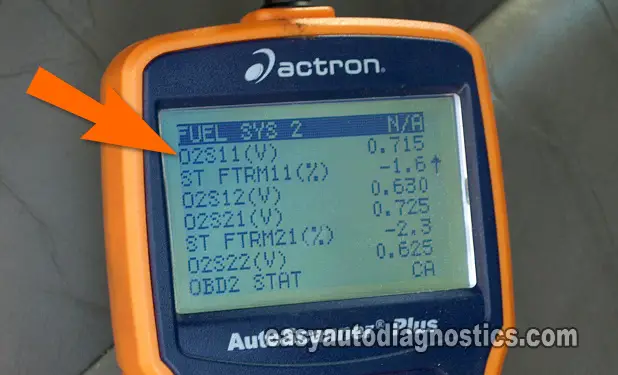

Once you're in Live Data mode, scroll down to the PID labeled: 02S11, see the photo in the image viewer above to see what this looks like (if you don't have a scan tool and you need to buy one, check out my recommendation here: Actron CP9580 Scan Tool Review -at troubleshootmyvehicle.com).

This is the PID that will show you what the O2 sensor is up to as the engine runs. - 2

Start the engine and let it warm up. Let the engine run for about 10 to 15 minutes.

The optimal engine temperature range, to get the best result from this test, is to have the coolant at 169° F (76° C). You can verify this coolant temperature with your scan tool also, in the PID that is labeled: Coolant. - 3

Once the engine has warmed up, take a look at the voltage numbers your scan tool is reading.

If the engine has been idling for about 15 minutes, the voltage numbers of the O2 sensor should be moving between 0.100 and 0.900 Volts constantly.

If the voltage value stays fixed, don't worry about this yet and continue to the next step. - 4

With the engine running, spray a little carburetor cleaner into a vacuum hose (that has engine vacuum) while you watch the oxygen sensor values on your scan tool.

If you spray too much, the engine will stall. If it happens, no big deal, just restart the engine and repeat the step and spray less carb cleaner spray. - 5

Almost immediately, after you spray the carb spray into the vacuum hose, the voltage numbers of O2S11 should spike to 0.900 Volts (on your scan tool). And as long as you're spraying, these voltage numbers should stay there.

- 6

Now, stop spraying carburetor spray and check the reaction of the oxygen sensor values.

What you should see, after a few seconds after you have stopped spraying, is the O2 sensor values start oscillating between 0.100 Volts to 0.900 Volts.

OK, the test is done, let's take a look at what your test results mean:

CASE 1: O2S11 voltage numbers spiked to 0.900 Volts when you sprayed carb spray into the vacuum hose. This tells you that the oxygen sensor is OK at this point in time.

More to the point, it tells you that the O2 sensor is responding fast enough and that it is not worn out. This also tells you that it does not need to be replaced, since whatever's causing the PCM to think it's fried is something else.

For more info on this, go to the section: Oxygen Sensor Codes Keep Coming Back.

CASE 2: O2S11 voltage numbers DID NOT spike to 0.900 Volts when you sprayed carb spray into the vacuum hose. This confirms that Bank 1 Oxygen Sensor 1 is no longer working. You can replace the oxygen sensor.

Oxygen Sensor Codes Keep Coming Back

So you tested the oxygen sensor and they tested good or you have already replace one or both and yet the PCM keeps accusing them as being bad (which also means that the check engine light is back on).

When this happens, it's usually due to either a Rich condition or Lean condition that's being caused by some other component on the engine.

What this means is that something other than the PCM is causing the oxygen sensor to report a Lean (or Rich) condition all of the time. Here are some common causes:

Rich Condition :

- Leaking fuel injector.

- Leaking fuel pressure regulator.

- Other sensors that have failed.

Lean Condition :

- Intake manifold gasket leaks.

- Exhaust manifold gasket leaks.

- Failing fuel pump not sending enough fuel to the engine.

Although testing all of the above conditions are beyond the scope of this article, all of the above components can be tested to make sure they're bad (before replacing them).

Related Test Articles

To see all of the 1.8L and 2.4L Mitsubishi (Dodge, Chrysler) specific articles here at troubleshootmyvehicle.com, go to: Mitsubishi 2.4L Index Of Articles.

Here's a sample of the articles, you'll find in the Index of Articles:

- Ignition Coil And Crank Sensor Tests (1.8L, 2.4L Mitsubishi).

- MAF Sensor Test (2.4L, 3.0L Mitsubishi 1999-2004).

- How To Test The Throttle Position Sensor (TPS).

- Testing A Bad Alternator: Symptoms And Diagnosis.

- How To Bench Test A Starter Motor (Step By Step).

If this info saved the day, buy me a beer!