Blower Resistor Continuity Specification Tables

The following blower resistor assembly resistance values I got from a good working blower motor resistor assembly. You'll notice that I got a good continuity reading from all of them.

NOTE: You're probably not gonna' see the exact same results from your test. You'll probably see a ±2 Ohms difference and this is normal. The result that'll tell you that the blower motor resistor is bad is a no-continuity test result between any 2 terminals.

| Terminal | Terminal | Resistance |

|---|---|---|

| 4 | 3 | 0.1 Ohms |

| 3 | 2 | 0.7 Ohms |

| 2 | 1 | 0.8 Ohms |

| 1 | 5 | 1.8 Ohms |

| 4 | 5 | 3.1 Ohms |

| 4 | 1 | 1.5 Ohms |

| 4 | 2 | 0.8 Ohms |

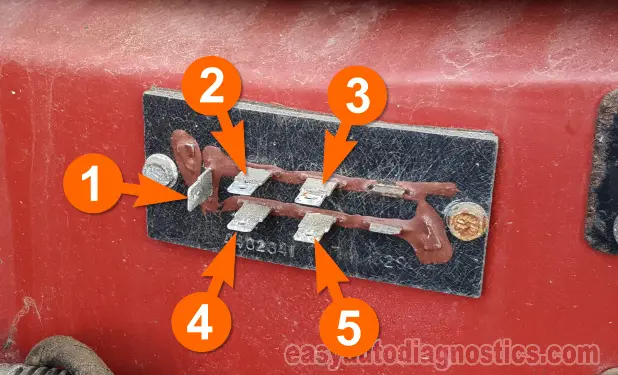

Example Of Damaged Blower Resistor Assembly Connector

The damage on the blower motor resistor above is a sure sign that the blower resistor assembly is bad.

More 3.9L Dodge Dakota Tutorials

You can find a complete list of 3.9L V6 Dodge Dakota tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The Starter Motor (1991-1995 3.9L Dodge Dakota).

- How To Test Engine Compression (1993-2003 3.9L Dodge Dakota).

- How To Test For A Blown Head Gasket (1993-2003 3.9L Dodge Dakota).

- Engine Management Sensor Circuit Diagram (1994-1995 3.9L V6 Dodge Dakota).

If this info saved the day, buy me a beer!