When the crankshaft position (CKP) sensor fails on your 3.9L V6 Dodge Dakota the engine is not gonna' start due to a lack of spark.

In this tutorial, I'll explain how to test the crankshaft position sensor on your 1997-2003 3.9L V6 Dodge Dakota and 1998-1999 3.9L Dodge Durango.

By the way, the crankshaft position sensor test can be done with a simple multimeter and since this is an on-car test, you don't have to remove it from your Dodge Dakota to test it.

NOTE: These tutorials compliment this one:

- Testing The Ignition System (1998-2003 3.9L Dodge Dakota).

- How To Test The Camshaft Position Sensor (1998-2003 3.9L Dodge Dakota).

Contents of this tutorial:

- Symptoms Of A Bad Crankshaft Position Sensor.

- Circuit Descriptions Of The Crankshaft Position Sensor.

- Where To Buy The Crankshaft Position Sensor.

- TEST 1: Testing The Crankshaft Position Signal.

- TEST 2: Making Sure The Crank Sensor Has Power.

- TEST 3: Making Sure The Crank Sensor Has Ground.

- More 3.9L Dodge Dakota Tutorials.

![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor De La Posición Del Cigüeñal (1997-2003 3.9L Dodge Dakota) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor De La Posición Del Cigüeñal (1997-2003 3.9L Dodge Dakota) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles since they use the exact same crankshaft position sensor:

- 3.9L Dodge Dakota: 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- 3.9L Dodge Durango: 1998, 1999.

WIRING DIAGRAM: The following ignition system wiring diagrams may come in handy:

- Ignition System Circuit Diagram (1997-1999 3.9L Dodge Dakota).

- Ignition System Wiring Diagram (2000 3.9L Dodge Dakota).

- Ignition System Wiring Diagram (2001-2003 3.9L Dodge Dakota).

Symptoms Of A Bad Crankshaft Position Sensor

For the most part crankshaft position sensor failures cause one of two problems: It'll fail completely and the engine won't start due to a lack of spark.

Or it'll fail intermittently. In this type of crankshaft position sensor failure, the engine runs starts and runs fine most of the time. But every now and then the engine doesn't start or if it's running, it stalls (dies) without any apparent reason.

The most common type of crankshaft position sensor failure that I've had to diagnose is the one where the sensor fails completely and causes a no-start problem. I'm gonna' focus on this type of failure in this tutorial.

Although the fuel injection computer is designed to set a trouble code P0320: No Crank Reference Signal At PCM when the crankshaft position sensor fails, it doesn't always do so.

Circuit Descriptions Of The Crankshaft Position Sensor

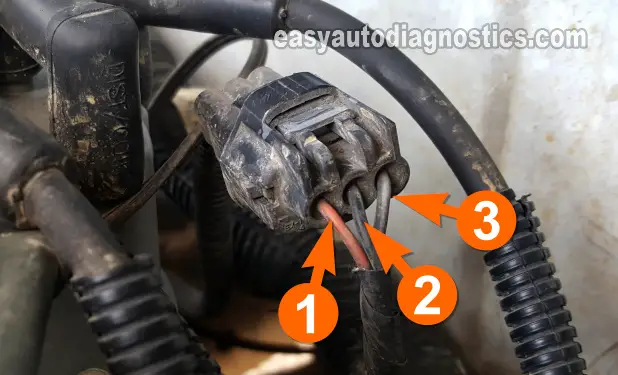

The crank sensor is a Hall Effect sensor and has 3 wires coming out of its electrical connector. This means that one wire feeds it with power, one wire feeds it Ground, and the other takes the CKP signal to the computer.

All three wires connect directly to your Dodge Dakota or Durango's fuel injection computer.

The connector on the sensor itself has male spade terminals. The connector on the engine wiring harness has female terminals.

Below is a brief description of the three wires that connect to the crankshaft position sensor:

| 1997-1999 Crankshaft Position Sensor Connector | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | Violet with white stripe (VIO/WHT) | Power (5 Volts DC) |

| 2 | Black with light blue stripe (BLK/LT BLU) | Sensor Ground |

| 3 | Gray with black stripe (GRY/BLK) | CKP Signal |

| 2000-2003 Crankshaft Position Sensor Connector | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | Orange (ORG) | Power (5 Volts DC) |

| 2 | Black with light blue stripe (BLK/LT BLU) | Sensor Ground |

| 3 | Gray with black stripe (GRY/BLK) | CKP Signal |

Where To Buy The Crankshaft Position Sensor

Checkout the following links and comparison shop the crankshaft position sensor for your 1997-2003 3.9L V6 Dodge Dakota:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

NOTE: Not sure if the crankshaft position sensor fits your particular 3.9L Dodge Dakota or Durango? Don't worry. Once you get to the site, they'll make sure it fits. If it doesn't, they'll find you the right one.

TEST 1: Testing The Crankshaft Position Signal

The crankshaft position sensor is designed to produce an ON/OFF voltage pulse when the engine is turning.

ON is when the signal voltage is 5 Volts DC and OFF is when the signal is 0 Volts DC.

The cool thing is that we can easily 'see' this ON/OFF voltage signal with a multimeter that's connected to the crankshaft position sensor's signal wire.

Now when the crankshaft position sensor fails, it's gonna' stay stuck producing a single voltage value as the engine turns.

To test the crankshaft position sensor with a multimeter, it's important to manually turn the engine and NOT use the starter motor! The starter motor will turn the engine too fast and you won't be able to see the ON/OFF voltage pulses.

One last thing before we start: The crankshaft position sensor is bolted to the transmission bell housing. The camshaft position sensor is located inside the distributor. The sensor we're testing is the crankshaft position sensor that's bolted to the transmission bell housing.

IMPORTANT: The crankshaft position sensor must be connected to its engine harness connector for this test to work. You'll need to connect your multimeter test lead to a back probe or a wire piercing probe to read the crank signal. You can see an example of a wire piercing probe here: Wire Piercing Probe Review (Power Probe PWPPPPP01).

NOTE: Don't have a multimeter or need to upgrade yours? Check out my recommendation: Buying A Digital Multimeter For Automotive Diagnostic Testing.

These are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

Disconnect the ignition coil from its electrical connector. This is an important safety precaution!

- 3

With the red multimeter test lead, probe the gray with black stripe (GRY/BLK) wire of the crank sensor connector.

NOTE: The crankshaft position sensor must remain connected to its engine wiring harness connector to be able to read its signal. - 4

Connect the black multimeter test lead directly on the battery negative (-) terminal.

- 5

Turn the ignition key to the ON position and turn the engine by hand using the 1/2" ratchet wrench and appropriate socket on the crankshaft pulley.

For the accuracy of the test, do not use the starter motor. - 6

Your multimeter will read an ON/OFF voltage of 5 Volts and 0 Volts (if the crankshaft position sensor is functioning correctly).

ON is when the multimeter reads 4-5 Volts DC and OFF is when it reads 0 Volts DC.

Let's examine your CKP signal test result:

CASE 1: The multimeter read the indicated ON/OFF DC voltage. This is the correct and expected test result and tells you that the crankshaft position sensor is functioning correctly.

Since the crankshaft position sensor IS NOT defective, something else is causing your 3.9L V6 Dakota or Durango to not start.

CASE 2: The multimeter DID NOT read the indicated ON/OFF DC voltage. This test result usually means that the crankshaft position sensor is defective.

Before you replace it, make sure it's getting power and Ground. For the next test go to: TEST 2: Making Sure The Crank Sensor Has Power.