Interpreting The Compression Test Results

I'm pretty sure that some of the compression values you got in TEST 1 were low compared to the majority of the cylinders.

This is especially common in high-mileage engine or engines that haven't seen a whole lot of maintenance. In some cases these low compression values don't cause a problem.

It's only when these low compression values vary more than 15% of the highest value that you're gonna' have a problem.

The cool thing is that we can find out easily by doing some math. So that I can better explain this 15% thing, I'll use the following compression test results:

- Cylinder #1 175 PSI.

- Cylinder #2 165 PSI.

- Cylinder #3 160 PSI.

- Cylinder #4 120 PSI.

- Cylinder #5 150 PSI.

- Cylinder #6 150 PSI.

The next step is to do the following math:

- Multiply .15 (15%) by the highest value: 175 x 0.15. This gives us 26.25, but we'll round it out to 26.

- Next, we subtract 26 from 175: 175 - 26 = 144.

- So now we know that the lowest possible compression value is: 144 PSI.

This means that cylinder #4, which has a compression value of 120 PSI, is the one causing the misfire because it's below the 144 PSI minimum.

Once we've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Compression Test.

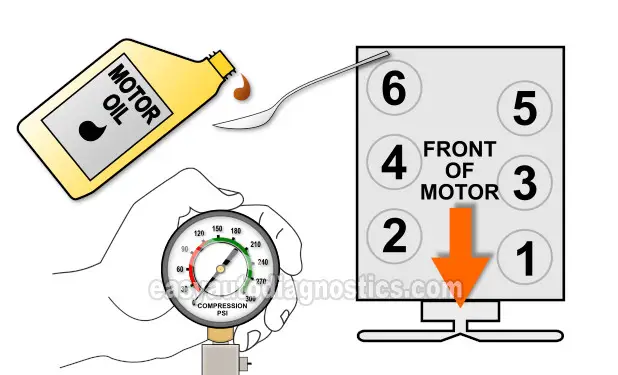

TEST 2: Wet Engine Compression Test

What usually causes a dead cylinder to have a low or 0 PSI compression value is one of two things: Either that cylinder's piston rings are worn out or its cylinder head valves are worn out or damaged.

We can easily find out by doing a 'wet' compression test on the cylinder or cylinders with low compression.

In a nutshell, the wet compression test simply involves adding about two tablespoons of engine oil to the cylinder with low compression and then testing its compression again.

If that dead cylinder's compression value increases, then you can conclude that its piston rings are worn out and causing the problem.

If the dead cylinder's compression value does not increase, then you can conclude that its cylinder head valves have a problem and are behind the low or 0 PSI compression value.

These are the test steps:

- 1

Add 1 or 2 tablespoon of engine oil in the cylinder you need to retest. I suggest using a small and long funnel so that the oil will reach the inside of the cylinder.

- 2

Install the compression gauge on the cylinder you just added oil to.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder, or...

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

Repeat steps 1 thru' 4 on any other cylinder you need to check.

Let's examine your test results:

CASE 1: The compression value of the cylinder you added oil to increased. This test result tells you that the low or near 0 PSI compression value is due to worn out piston rings of that specific cylinder.

CASE 2: The compression value of the cylinder you added oil to DID NOT increase. This test result confirms that the cylinder head valves of that cylinder are worn-out or damaged.

More 3.9L Dodge Dakota Tutorials

You can find a complete list of 3.9L Chrysler and Dodge tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- Testing The Ignition System (1998-2003 3.9L Dodge Dakota).

- How To Test The MAP Sensor (2000-2003 3.9L V6 Dodge Dakota).

- How To Test The TPS Sensor (2000-2003 3.9L V6 Dodge Dakota).

- How To Test For A Blown Head Gasket (1993-1999 3.9L Dodge Dakota).

- Engine Management Sensor Circuit Diagram (1994-1995 3.9L V6 Dodge Dakota).

If this info saved the day, buy me a beer!