Testing the 5 terminal blower motor resistor block, used in the 2000 Dodge Dakota and 2000 Dodge Durango, involves two tests.

One is visually inspecting the resistor block for burn damage and corrosion and the other is a simple multimeter continuity test.

NOTE: This tutorial covers the ‘old style’ blower motor resistor assembly which uses metal coil resistors.

Contents of this tutorial at a glance:

You can find the blower motor test here: How To Test The Blower Motor (2000 Dodge Dakota).

NOTE: The 1997-1999 Durango and Dakota use a 4 terminal resistor block. You can find that test here: How To Test The Blower Motor Resistor (1997-1999 Dodge Dakota And Durango).

For the 2001-2004 blower resistor block test, see this tutorial: How To Test The Blower Motor Resistor (2001-2004 Dakota, Durango).

![]() You can find this tutorial in Spanish here: Cómo Probar La Resistencia Del Motor Soplador (2000 Dodge Dakota Y Durango) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Resistencia Del Motor Soplador (2000 Dodge Dakota Y Durango) (at: autotecnico-online.com).

Blower Motor Resistor Basics

The 2000 Dodge Dakota and Durango come equipped with a resistor block with actual metallic coils.

The blower motor resistor block (covered by this tutorial) is located behind the dash, where the firewall meets the windshield. Yup, you have to remove the dash to get to it.

When the blower motor resistor block fails, you'll usually see one of the following symptoms:

- Blower motor works in high-speed only.

- Blower motor works in some speeds, but NOT all speeds.

It's very common for the resistor connector terminals to corrode or for the connector to burn and melt. This will make disconnecting the connector from the blower motor resistor block very difficult.

Another common problem is finding the resistor block coils corroded or burned out when removing the resistor block for testing.

Where To Buy The Blower Motor Resistor

Since it's common for the 5 terminal resistor block to overheat and melt its connector, I've also included the link to the connector.

The 5 terminal blower motor resistor block, for the Dodge Dakota isn't expensive. The following links will help you comparison shop and save a few bucks:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Resistance Testing The Blower Motor Resistor

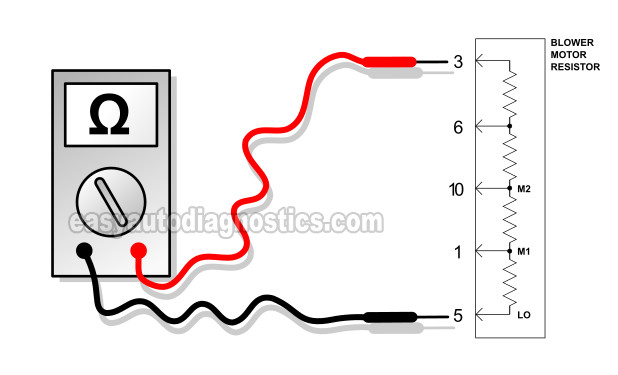

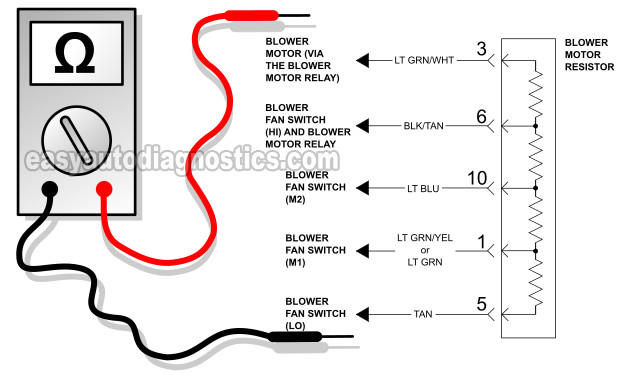

We're gonna' test the continuity of the blower motor resistor with a multimeter in Ohms mode.

You don't have to remove the resistor block to test it, but if you do you'll be able to inspect it for broken or burned resistors (coils). Remember to check its connector for any type of damage too.

If you find any type of burn damage on the resistor block and connector, you can conclude they are bad and need to be replaced (and skip the continuity tests).

NOTE: To see actual resistance specifications for the continuity test of this test section, go here: Blower Resistor Continuity Specification Tables.

OK, let's get started:

- 1

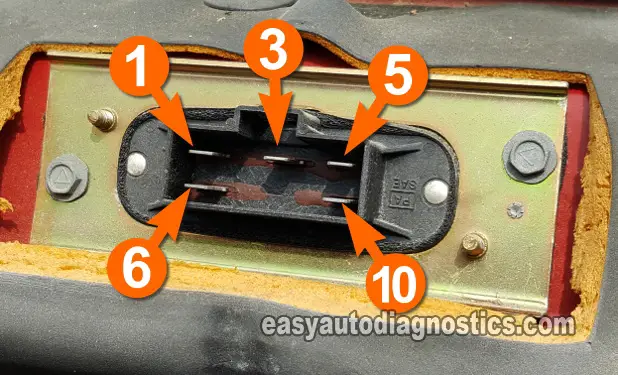

Disconnect the blower motor resistor from its connector and remove it from its location.

- 2

Visually inspect the blower motor resistor block and connector for burn damage and severe corrosion.

- 3

Place your multimeter in Ohms mode.

- 4

Check for continuity across two terminals at a time. Continuity should be present between all terminals.

NOTE: If continuity DOES NOT exist between 2 terminals, your multimeter will display the letters OL (Open Loop).

Let's take a look at what your test results mean:

CASE 1: Continuity exists between all the blower motor resistor terminals. This is the correct and expected test result.

If there isn't any burn damage to the resistor's coils or its connector, then you can conclude the blower motor resistor block is OK and not defective.

CASE 2: Continuity DOES NOT exist between some of the blower motor resistor terminals. This test result tells you that the blower motor resistor is defective and needs to be replaced.

If the resistor block's connector is damaged or is melted, it must be replaced with a new one.