This tutorial will help you test the throttle position sensor (TPS) on the 1997, 1998, and 1999 V8 Dodge Dakota and Durango.

It's a very easy test that's done with a multimeter and will help you find out if it's defective (or not).

By the way, the TPS test requires no scan tool!

Contents of this tutorial at a glance:

![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1997-1999 Dodge Dakota Y Durango) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1997-1999 Dodge Dakota Y Durango) (at: autotecnico-online.com).

Symptoms Of A Bad Throttle Position Sensor

When the TPS goes bad, the very first thing you'll notice is the check engine light shining nice and bright on your Dodge Dakota or Durango's instrument panel.

You'll see one of the following trouble codes:

- A TPS diagnostic trouble code (DTC) stored in the PCM's memory:

- P0121: TPS Voltage Does Not Agree With MAP.

- P0122: Throttle Position Sensor Voltage Low.

- P0123: Throttle Position Sensor Voltage High.

Besides the check engine light illuminated, you'll see one or more of the following symptoms:

- Hard start and/or extended cranking time (after shut off).

- Black smoke coming out of the tailpipe.

- Hesitation when accelerating your vehicle down the road.

- Bad gas mileage.

As mentioned at the beginning of this tutorial, the TPS can be tested without a scan tool and in the next section we'll start with the very first test.

TEST 1: Testing The Throttle Position Sensor Voltage Signal

In a nutshell, the TPS creates a voltage signal that increases as the throttle plate opens and decreases as it closes back to its original position.

When it fails, it'll usually stay stuck producing one single voltage no matter the throttle plate angle.

What we'll do, to test the TP sensor's performance is to tap into the TP signal wire, with our multimeter, and check the signal's voltage as we open and close the throttle plate.

This is a very simple test done with a multimeter in Volts DC mode.

NOTE: Don't have a multimeter or need to upgrade yours? Check out my recommendation: Buying A Digital Multimeter For Automotive Diagnostic Testing.

OK, let's start:

- 1

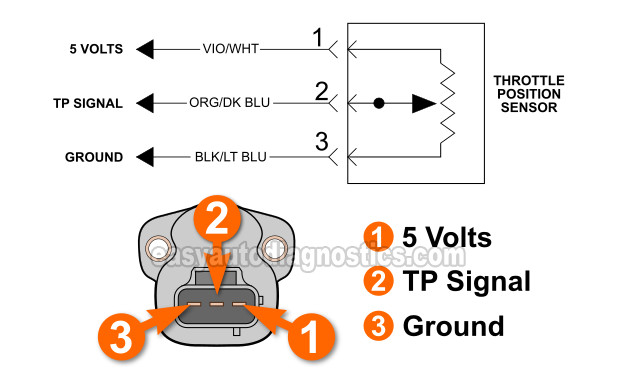

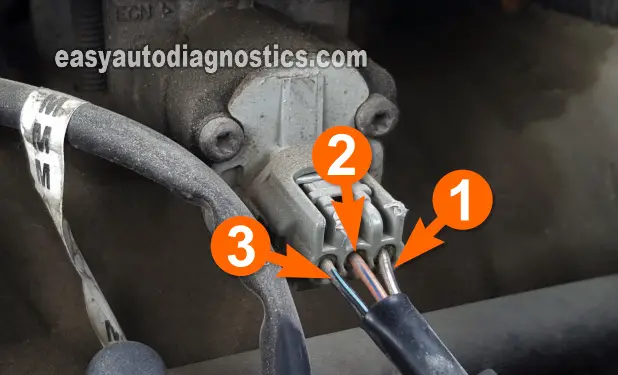

Place your multimeter in Volts DC mode and connect the red test lead to the RED/BLK wire of the TP sensor harness connector.

NOTE: The TP sensor connector needs to be connected to the TPS, so you'll need to either back-probe the connector or use a wire piercing probe to get to the signal inside the wire (to see what a wire piercing probe looks like: Wire Piercing Probe Tool). - 2

Ground the black multimeter test lead directly on the battery negative (-) post.

- 3

Manually rotate the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 4

The multimeter should show an increasing voltage as you (or your helper) open up the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 5

The multimeter should show a decreasing voltage as you begin to close the throttle.

- 6

Using a screwdriver's handle, gently tap the TP sensor as you open and close the throttle and observe the multimeter.

The purpose (of tapping the TP sensor with the screwdriver's handle) is to see if the TP sensor shows gap's in the voltage signal. Why? Because a good TP sensor will show a continuous increasing or decreasing voltage signal even while getting tapped by the screw-driver's handle.

Let's take a look at your test results:

CASE 1: The TP sensor signal's voltage increased and decreased smoothly and without gaps. This is the correct test result and it tells you that your Dodge Dakota or Durango's TPS is working correctly.

You can also conclude that the throttle position sensor is getting power and Ground.

CASE 2: The TP sensor signal's voltage did not increase or decrease. This test result usually means that the TP sensor is defective, but not always.

The next step, before calling the TP sensor defective, is to make sure that it's getting power and Ground. For these two tests, go to: TEST 2: Checking Throttle Position Sensor (TPS) Power and Ground.

CASE 3: The TP sensor signal's voltage showed gaps in its voltage output as you tapped the sensor with the screwdriver. If the voltage signal (on your multimeter) reacted to the screwdriver tapping on the TP sensor, then this is a sure sign that the TPS is defective and needs to be replaced.