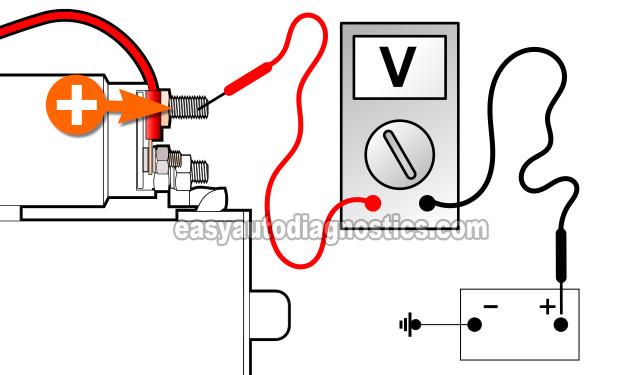

TEST 3: Voltage Drop Testing The Battery (+) Cable

What we're gonna' do is check the battery cable that connects to the starter motor. The purpose of this test is to see if hidden corrosion on the cable is keeping the full amount of current (available from the battery) from reaching the starter motor.

If the starter motor doesn't get a certain amount of current, it won't turn over your Ford Ranger's engine.

This is a very easy and simple test that's done with a multimeter and is known as a voltage drop test.

IMPORTANT: Don't disconnect the battery cable from the starter motor's solenoid. In the illustration above the battery cable is disconnected from the starter motor just to make it easier to show the multimeter test connections.

Let's get started:

- 1

Place your multimeter in Volts DC mode.

- 2

Attach the black multimeter test lead to the center of the positive (+) battery terminal.

If the positive battery post isn't clean, clean a spot right on the top of it. It's important that the multimeter lead make contact right in the center of the positive battery post. - 3

Connect the black multimeter test lead to the center of the stud to which the big battery cable attaches to on the starter solenoid.

- 4

Have your helper crank the engine even though the starter motor isn't cranking the engine.

This is important, since a voltage drop test has to be done while the component in question is working (or trying to work). - 5

If all is good (no voltage drop), your multimeter will register 0 Volts (.5 Volts is still 0 Volts).

If there's a voltage drop (which is bad), your multimeter will register voltage (usually above 7 Volts DC.)

Let's take a look at what your results mean:

CASE 1: Your multimeter registered 0 Volts (no voltage drop). This is the correct test result. With this result you can conclude that the starter motor is getting enough current to crank the engine.

You can conclude your Ford Ranger or Mazda B2300's starter motor is defective if you have:

- Confirmed that the starter motor doesn't work when you apply power to the S terminal wire of the starter motor (TEST 1).

- Confirmed that the starter motor is receiving the crank signal (TEST 2).

- In this test step, you have confirmed that no voltage drop exists on the battery positive cable.

Replacing the starter motor should solve your no-crank condition.

I'm going to make two more recommendations to you:

- Before removing the starter motor, manually turn the engine using a 1/2 ratchet and the appropriate socket. This is to make sure that the engine or the A/C compressor have not locked up and causing the no-crank condition.

- Bench test the starter motor after removing it. This is a super easy test to do and this tutorial will help: Bench Testing The Starter Motor.

CASE 2: Your multimeter registered 5 Volts or more. This result tells you that a voltage drop does exist and that the battery's full power is not reaching the starter motor.

The good news is that this can easily be corrected, since a voltage drop is always caused by some sort of corrosion issue on the battery positive cable or terminals or the battery positive post.

The solution is to thoroughly clean the battery positive post and the battery positive (+) terminal (both the end that attaches to the battery positive post and the end the connects to the starter motor's battery (+) cable stud.

After cleaning, try cranking the engine. If it cranks and starts, no further testing is required.

More 2.3L Ford Tutorials

You can find a complete list of tutorials here: Ford 2.3L Index Of Articles.

Here's a sample of the tutorials you'll find there:

- 1992-1994 2.3L Ford Ranger Fuel Injector Wiring Diagram.

- How To Test The Throttle Position Sensor (2.3L Ranger, Mustang, B2300).

- How To Test The Ignition Module And Crank Sensor (2.3L Ranger, Mustang, B2300).

- How To Test For A Blown Head Gasket (2.3L Ranger, Mustang, B2300).

- How To Test The Fuel Injectors (1990-1997 2.3L Ford) (at: troubleshootmyvehicle.com).

If this info saved the day, buy me a beer!