TEST 2: Applying Power And Ground To The Blower Motor

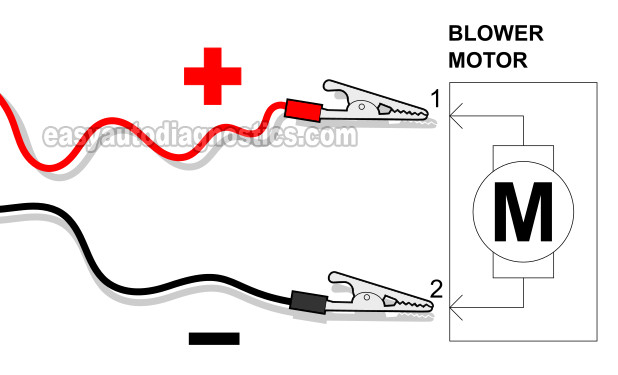

In this test section, we're gonna' directly apply battery power and Ground to the blower motor.

Depending on the amount of access, you might need to remove the blower motor to access the blower motor's metal terminals.

Alright, let's get testing:

- 1

Disconnect the blower motor from its electrical connector.

The connector has 2 wires. The brown with orange stripe wire (BRN/ORG) wire supplies power and the orange with black stripe (ORG/BLK) wire supplies Ground (via the blower resistor and blower switch). - 2

Apply battery power to the blower motor.

You'll be applying power to the male spade terminal (of the blower motor itself) that connects to the BRN/ORG wire of the electrical connector. - 3

Apply chassis Ground to the blower motor.

You'll be applying Ground to the male spade terminal (of the blower motor itself) that connects to the ORG/BLK wire of the electrical connector. - 4

The blower motor should run.

Let's take a look at your test results:

CASE 1: The blower motor ran and without bearing noise. This is the correct test result.

CASE 2: The blower motor ran but with a lot of bearing noise. This tells you that the blower motor is failing and should be replaced.

Usually, when the blower motor runs with a lot of bearing noise, its amperage draw is at or above 30 Amps.

CASE 3: The blower motor DID NOT run. This test result tells you that the blower motor is defective. Replace the blower motor.

More 3.0L Ford Ranger Tutorials

You can find a complete list of 3.0L Ford Ranger tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- Tune Up And Torque Specifications 1991-1994 3.0L Ford Ranger.

- How To Test The TPS (1993-1994 3.0L Ford Ranger).

- How To Test The Fuel Injectors (1992-1994 3.0L Ford Ranger).

- How To Test The Fuel Pump (1992-2000 3.0L Ford Ranger) (at: troubleshootmyvehicle.com).

If this info saved the day, buy me a beer!