TEST 3: Engine Compression Test

On some occasions, when the engine overheats and the head gasket fails, it burns right between two cylinders.

The end result is the compression from one cylinder escaping into the other and vice versa, but coolant doesn't pass into the crankcase nor does the compression escape into the block coolant passages.

To be more specific, when this happens the oil doesn't get mixed with coolant and the compression/exhaust pressures don't get pushed out an open radiator.

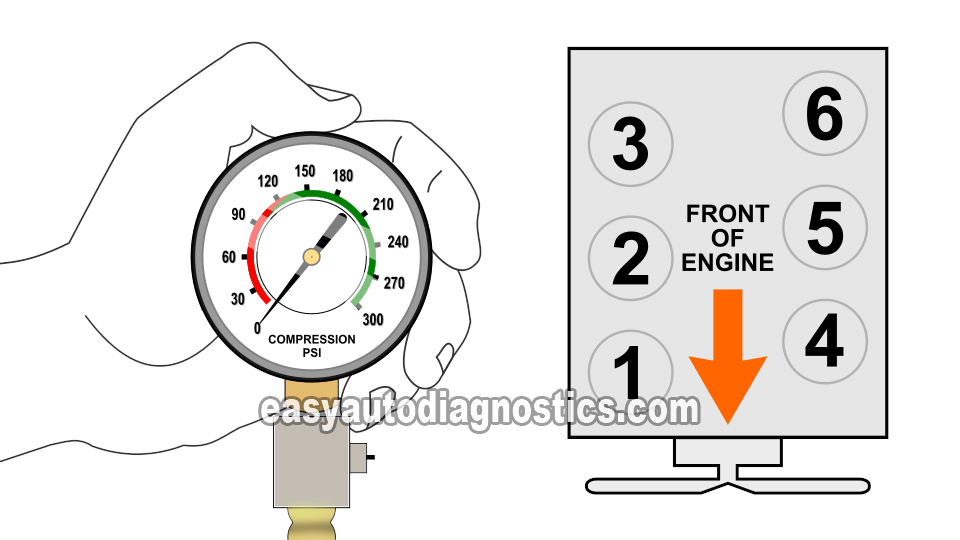

To test to see if the head gasket is burned between two side-by-side cylinders (of the same bank), we need to do a compression test.

NOTE: You can find the engine compression test explained in more detail here: How To Do An Engine Compression Test (1997-2003 4.2L V6 Ford F150, F250).

These are the steps:

- 1

Disable the fuel system and the ignition system.

You can easily accomplish this disconnecting the ignition coil pack from its electrical connector and removing the fuel pump relay. - 2

Remove the spark plugs.

Before you do, label all of the spark plug wires with their cylinder numbers so that you can connect back to the correct spark plug when done. - 3

Install the compression tester (hand tight only) on the first cylinder you're gonna' test.

- 4

Have a helper crank the engine while you observe the compression tester.

- 5

Write down the compression readings.

You can use the illustration above to record the number of the cylinder. - 6

Repeat steps 1 through 5 on the next cylinders.

Let's examine your test results:

CASE 1: You got 2 side by side (adjacent) cylinders with 0 PSI. This confirms beyond a shadow of a doubt that you do have a blown head gasket on your hands.

CASE 2: All cylinders had sufficient compression. So far so good. All the tests you've done up until this point tell you that you don't have blown head gasket on your hands.

But, if you still suspect that you have a blown head gasket, I suggest doing a chemical block test as explained in the next test section: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

TEST 4: Using A Chemical Block Tester (Combustion Leak Tester)

One of the most important and effective ways to test for a head gasket problem is a chemical block test.

This is due to the fact that in some occasions the engine has a blown head gasket issue, or a cracked block issue, or a cracked cylinder head issue, but the previous 3 tests don't catch it. The only way to be sure it's a head gasket problem or not is doing a chemical block test.

The combustion leak tester (or block tester) test is so effective that it's used in all major/competent repair shops to confirm a blown head gasket issue. In a nutshell this is how the test works:

- A blue liquid chemical, which is blue in color, is placed in the tester (see photo above).

- The tester assembly is then placed on the open radiator neck (you may have to drain some of the coolant in the radiator since this tool needs to 'gulp' some of the air inside the radiator).

- The rubber bellow is then squeezed to suck in the air up through the two fluid-filled chambers. As the air bubbles up through the fluid, it will cause a chemical reaction.

- If the blue chemical turns yellow (for gasoline engines), then combustion gases are entering the radiator. This result confirms a blown head gasket, a cracked block, or a cracked cylinder head issue.

- If the blue chemical doesn't change color, then you can conclude that you don't have a blown head gasket, a cracked block, or a cracked cylinder head issue.

Where can you get the chemical and block tester? Here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

Frequently Asked Questions

1.) How can I tell if the cylinder head is cracked?

The only way to know is to remove the cylinder head and visually inspect it. If the crack is wide enough, you'll be able to easily see it.

In many instances, a visual inspection won't be enough, you'll need to have the machine shop, that's gonna' resurface the cylinder head, for a pressure test.

2.) Do I need to resurface the cylinder head?

The answer is YES! You should never reinstall the cylinder head or cylinder heads without first having a Machine Shop resurface the cylinders heads (particularly over an overheating condition).

Now, of course, if you (or the machine) have checked it with a straight-edge and there's no warpage, then, and only then is the cylinder head not resurfaced.

3.) Do I need to remove both cylinder heads from my Ford V6?

Yes, you need to remove them both. In a professional setting, it's standard practice to remove them both and replace both cylinder head gaskets (and have both cylinder heads resurfaced).

This is important because the only way to make sure the other cylinder head isn't extremely warped or cracked is by removing it and and visually inspecting it and taking the necessary warp measurements with a straight edge and doing a pressure test.

More 4.2L Ford F150 And F250 Diagnostic Tutorials

You can find a complete list of 4.2L Ford F150 and F250 tutorials and wiring diagrams in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Do An Engine Compression Test (1997-2003 4.2L V6 Ford F150, F250).

- How To Test The Fuel Injectors (2001-2003 4.2L V6 Ford F150, F250).

- How To Test The Throttle Position Sensor (1997-2000 4.2L V6 Ford F150, F250).

- How To Test The Ford EGR Valve EGR Vacuum Solenoid, DPFE Sensor.

- How To Test The Coil Pack (Ford 3.0L, 3.8L, 4.0L, 4.2L).

If this info saved the day, buy me a beer!