Testing engine compression is probably one of the most over-looked tests when diagnosing a hard to find misfire or no-start condition.

In this tutorial, I'll show you how to do and interpret an engine compression test on 4.2L equipped Fords.

Contents of this tutorial:

![]() You can find this tutorial in Spanish here: Cómo Verificar La Compresión Del Motor (4.2L Ford V6) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Verificar La Compresión Del Motor (4.2L Ford V6) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 4.2L V6 Ford F150: 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- 4.2L V6 Ford F250: 1998.

E-SERIES VANS: The engine compression test tutorial for the 1997-2003 4.2L V6 Ford E150/E250 vans can be found here:

- How To Test Engine Compression (1997-2003 4.2L V6 Ford E150, E250) (at: troubleshootmyvehicle.com).

Important Tips And Suggestions

TIP 1: If possible, it's a good idea to warm up the engine for about 10 minutes (from a completely cold condition). The key words here are 'slightly warmed up engine' since the engine should not be hot.

A slightly warmed up engine will improve the accuracy of your compression test results.

TIP 2: Take all necessary safety precautions as you work around a cranking engine. Your safety is your responsibility, so use common sense and think safety all of the time.

TIP 3: Your 4.2L V6 Ford engine's cylinder heads are made of aluminum, so do not remove the spark plugs with a hot engine. Removing the spark plugs from a hot engine can/will damage the spark plug hole threads in the aluminum cylinder head.

Symptoms Of Low Or No Cylinder Compression

As mentioned at the beginning of this tutorial, engine compression issues usually cause one of two problems: a misfire condition or a no-start condition.

Low engine compression in one or more cylinders will cause a rough idle (misfire) issue that can seem very hard to diagnose.

No compression in all cylinders results in a 'cranks but does not start' condition.

Here are some other specific symptoms you may see with low cylinder compression:

- Engine cranks but does not start (0 compression in all cylinders).

- Blue smoke coming out of the tailpipe.

- Rough idle (engine misfires).

- Bad gas mileage.

- Engine 'misses' at idle but 'miss' disappears as you accelerate.

- Check engine light is illuminated with a MAP sensor trouble code (even tho' the MAP sensor is good).

- Misfire trouble codes: P0300, P0301, P0302, P0303, P0304, P0305, P0306.

With this info under our belts, let's head down to the next subheading and get testing.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make some recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Dry Compression Test

As you're already aware, doing a compression test involves disconnecting the spark plug wires from the spark plugs and then removing the spark plugs. To avoid damaging the spark plug wire and/or losing the firing order of the spark plug wires, I recommend two very important things:

- Label the spark plug wires with the cylinder number they belong to.

- Use a spark plug wire puller tool to unplug the spark plug wire from the spark plug.

Why use a spark plug wire puller? Cause pulling on the wire boot by hand can cause the wire's metal terminal to pull off and stay stuck on the spark plug. The following tutorial offers you more info: How To Use A Spark Plug Wire Puller And Where To Buy One.

OK, to get started this is what you'll need to do:

- 1

Disable the ignition system by disconnecting the ignition coil from its electrical connectors.

NOTE: This is a safety precaution that will prevent the ignition coil from sparking during the test. - 2

Disable the fuel system by disconnecting the fuel injectors.

NOTE: Disabling the fuel system will prevent fuel from being injected into each cylinder when the test is performed. - 3

Remove the spark plugs from a slightly warmed up engine (if it starts and runs). Remember, the engine can not be hot!

When removing the spark plugs, be careful not to drop any of them on the floor, or you run the risk of having the spark plugs porcelain insulator crack and then you'll have a misfire on your hands.

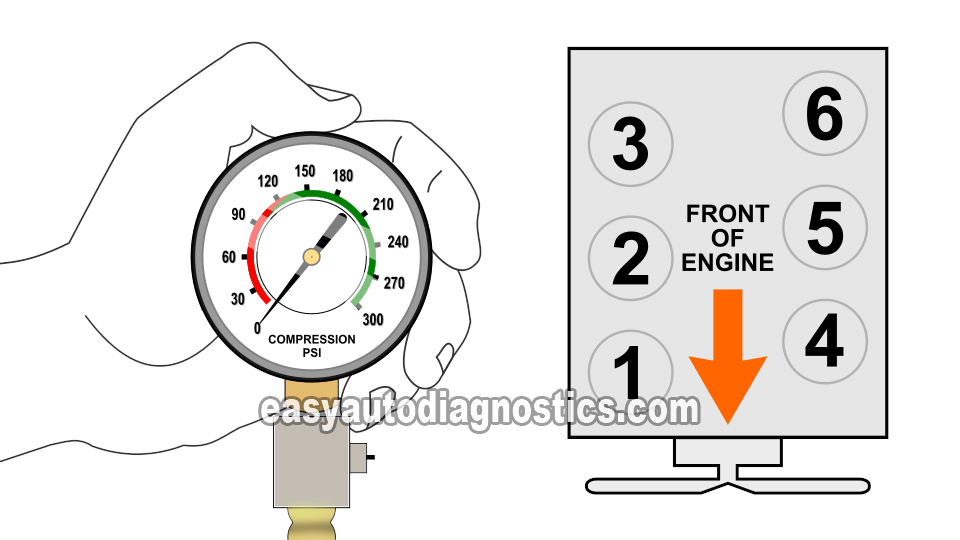

If the engine does not start, don't worry about it being warmed up. - 4

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder. Hand tighten the compression gauge only! Do not use any type of tool to get it tight.

- 5

Have your helper crank the engine till the needle on the compression gauge stops climbing.

- 6

Record the value at which the needle stopped and the number of the engine cylinder on a piece of paper.

- 7

Release the pressure on the gauge and check the cylinder's compression one more time.

- 8

Repeat test steps 4 thru 7 on the remaining cylinders.

Let's take a look at what your test results mean:

CASE 1: One or more cylinders had a much lower compression value than the others. Up to a certain range, this could be normal.

To further interpret these test results go to: Interpreting The Compression Test Results.

CASE 2: All six cylinders had almost no compression or 0 PSI compression. This low or zero compression on all cylinders will cause the engine to not start.

Having a compression value close to 0 PSI or 0 PSI is usually due one of the following problems:

- A busted timing chain.

- Blown head gasket.

- The engine threw a rod.

CASE 3: The compression value of all six cylinders was similar and above 120 PSI. This test result lets you know that an engine compression problem is not behind the misfire condition and/or engine no-start problem you're troubleshooting.

Interpreting The Compression Test Results

Some cylinders will have a lower compression value than the rest, especially if your pickup's engine has high mileage. Within a certain range, this lower compression value in the cylinder or cylinders won't cause any engine performance issues.

Engine performance problems start when a low cylinder compression value varies more than 15% from the highest. The most common engine performance issue you'll see is an engine idling rough or suffering from a misfire problem.

By doing some easy math, which I'll explain how to do in this test section, you can find out if these low compression values are causing an issue.

As a general rule, the lowest compression value shouldn't be more than 15% lower than the highest value you noted in TEST 1. If it's off by more than that, the engine cylinder will misfire. This misfire will make your Ford pickup's 4.2L V6 engine idle rough.

How do you figure this out? You can find out by using my online low compression calculator here: Online Low Engine Compression Calculator or by calculating this 15% difference manually.

To understand how to figure out this 15% thing manually, I'll use the following compression test results:

- Cylinder #1 175 PSI.

- Cylinder #2 165 PSI.

- Cylinder #3 170 PSI.

- Cylinder #4 120 PSI.

- Cylinder #5 170 PSI.

- Cylinder #6 170 PSI.

The next step is to do the following math:

- Multiply .15 (15%) by the highest value: 175 x 0.15. This gives us 26.25, but we'll round it out to 26.

- Next, we subtract 26 from 175: 175 - 26 = 144.

- So now we know that the lowest possible compression value is: 144 PSI.

This means that cylinder #4, which has a compression value of 120 PSI, is the one causing the misfire because it's below the 144 PSI minimum.

Once we've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

TEST 2: Wet Engine Compression Test

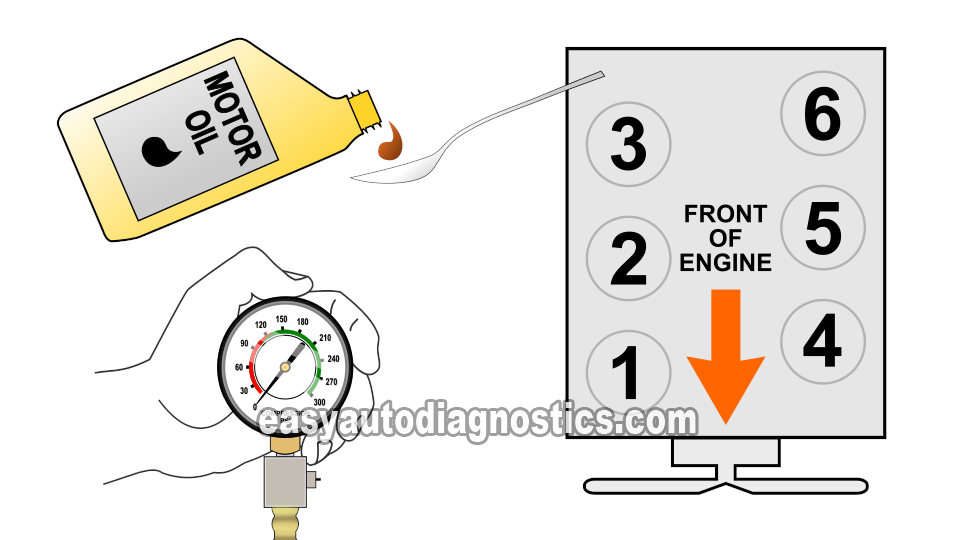

If in TEST 1 your test results indicate a cylinder or cylinders with low engine compression, the next step is to do a 'Wet' engine compression test.

This simply involves adding a small quantity of motor oil to the affected cylinder and then checking its compression again.

If the compression value rises (from the value you got and wrote down in TEST 1), then you now know that the compression rings are behind the low compression problem.

If the compression value DOES NOT increase, then you now know that the problem is due to bad cylinder head valve seats or bad cylinder head valves (in that affected cylinder).

OK, this is what you'll need to do:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest. I suggest using a small and long funnel so that the oil will reach the inside of the cylinder.

- 2

Once you've added the oil, install the compression gauge.

As before just hand tighten the gauge. - 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

Repeat steps 1 thru' 4 on any other cylinders you need to test.

Let's take a look at what your compression test results mean:

CASE 1: The compression value shot up for the low compression cylinder. This confirms that the low compression value registered in this cylinder in the dry test is due to worn piston rings.

The reason the compression value shot up is due to the fact that the motor oil you just added helped the piston rings to create a tighter seal. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: Your compression value DID NOT shoot up (stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

More 4.2L V6 Ford F150 And F250 Diagnostic Tutorials

You can find a complete list of 4.2L Ford F150/F250 tutorials and wiring diagrams in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The Fuel Injectors (2001-2003 4.2L V6 Ford F150, F250).

- How To Test The Throttle Position Sensor (4.2L Ford F150, E150, E250).

- How To Test The Ford EGR Valve EGR Vacuum Solenoid, DPFE Sensor.

- How To Test The Coil Pack (Ford 3.0L, 3.8L, 4.0L, 4.2L).

If this info saved the day, buy me a beer!