Interpreting The Compression Test Results

Some cylinders will have a lower compression value than the rest, especially if your pickup's engine has high mileage. Within a certain range, this lower compression value in the cylinder or cylinders won't cause any engine performance issues.

Engine performance problems start when a low cylinder compression value varies more than 15% from the highest. The most common engine performance issue you'll see is an engine idling rough or suffering from a misfire problem.

By doing some easy math, which I'll explain how to do in this test section, you can find out if these low compression values are causing an issue.

As a general rule, the lowest compression value shouldn't be more than 15% lower than the highest value you noted in TEST 1. If it's off by more than that, the engine cylinder will misfire. This misfire will make your Ford pickup's 4.2L V6 engine idle rough.

How do you figure this out? You can find out by using my online low compression calculator here: Online Low Engine Compression Calculator or by calculating this 15% difference manually.

To understand how to figure out this 15% thing manually, I'll use the following compression test results:

- Cylinder #1 175 PSI.

- Cylinder #2 165 PSI.

- Cylinder #3 170 PSI.

- Cylinder #4 120 PSI.

- Cylinder #5 170 PSI.

- Cylinder #6 170 PSI.

The next step is to do the following math:

- Multiply .15 (15%) by the highest value: 175 x 0.15. This gives us 26.25, but we'll round it out to 26.

- Next, we subtract 26 from 175: 175 - 26 = 144.

- So now we know that the lowest possible compression value is: 144 PSI.

This means that cylinder #4, which has a compression value of 120 PSI, is the one causing the misfire because it's below the 144 PSI minimum.

Once we've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

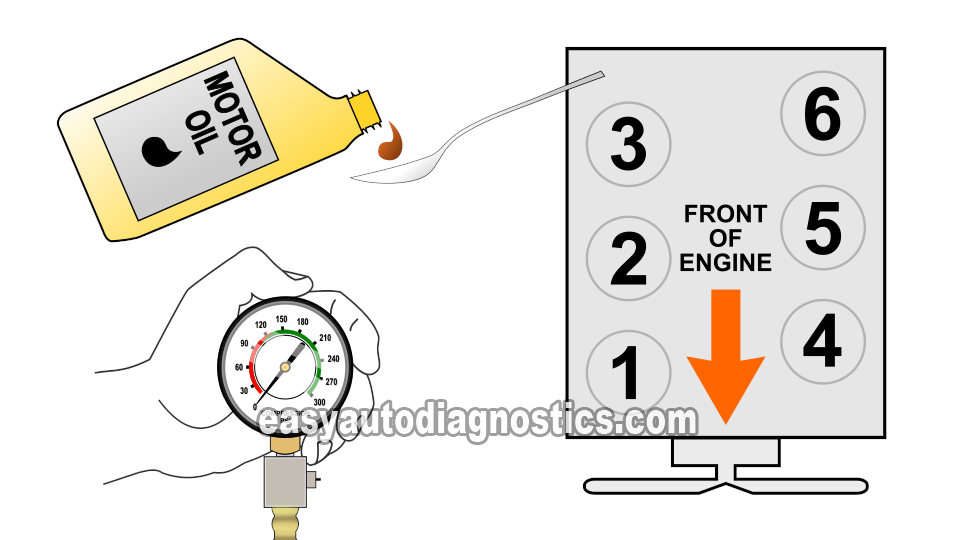

TEST 2: Wet Engine Compression Test

If in TEST 1 your test results indicate a cylinder or cylinders with low engine compression, the next step is to do a 'Wet' engine compression test.

This simply involves adding a small quantity of motor oil to the affected cylinder and then checking its compression again.

If the compression value rises (from the value you got and wrote down in TEST 1), then you now know that the compression rings are behind the low compression problem.

If the compression value DOES NOT increase, then you now know that the problem is due to bad cylinder head valve seats or bad cylinder head valves (in that affected cylinder).

OK, this is what you'll need to do:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest. I suggest using a small and long funnel so that the oil will reach the inside of the cylinder.

- 2

Once you've added the oil, install the compression gauge.

As before just hand tighten the gauge. - 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

Repeat steps 1 thru' 4 on any other cylinders you need to test.

Let's take a look at what your compression test results mean:

CASE 1: The compression value shot up for the low compression cylinder. This confirms that the low compression value registered in this cylinder in the dry test is due to worn piston rings.

The reason the compression value shot up is due to the fact that the motor oil you just added helped the piston rings to create a tighter seal. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: Your compression value DID NOT shoot up (stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

More 4.2L V6 Ford F150 And F250 Diagnostic Tutorials

You can find a complete list of 4.2L Ford F150/F250 tutorials and wiring diagrams in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The Fuel Injectors (2001-2003 4.2L V6 Ford F150, F250).

- How To Test The Throttle Position Sensor (4.2L Ford F150, E150, E250).

- How To Test The Ford EGR Valve EGR Vacuum Solenoid, DPFE Sensor.

- How To Test The Coil Pack (Ford 3.0L, 3.8L, 4.0L, 4.2L).

If this info saved the day, buy me a beer!