TEST 2: Coolant Shooting Out From Open Radiator

The second most common test that an automotive technician will perform to check for a blown head gasket is to see if coolant is shot out of the radiator (with the radiator cap removed) while the engine is cranking.

If coolant gets shot out of the radiator while cranking the engine, the head gasket is blown.

It's important to note that this test is done with a cold engine.

IMPORTANT: Do not remove the radiator cap from the radiator if the engine is hot or has been running for any length of time. Let the engine cool down completely before removing the cap from the radiator.

Let's get started:

- 1

Remove the radiator cap.

- 2

Check the coolant level in the radiator.

Add water or coolant if necessary. - 3

Have your helper crank the engine while you stand at a safe distance from the open radiator.

- 4

You'll see one of two results:

1.) The water or coolant inside the radiator will shoot out of the open radiator.

2.) The coolant remained undisturbed. In other words, cranking the engine will have no effect on the level of the water or coolant in the radiator.

Let's examine your test result:

CASE 1: The coolant shot out from the radiator as you cranked the engine. This confirms the head gasket is blown on your 2.2L Chevy S10 (GMC Sonoma).

CASE 2: The coolant DID NOT shoot out from the radiator. This is the correct and expected test result.

If the engine, in your 2.2L Chevy S10 (GMC Sonoma), starts but runs with a misfire, then next step is to test engine compression. For this test go to: TEST 3: Engine Compression Test.

If the engine starts but overheats almost immediately, then your next step is to do a 'block' test. For this test go to: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

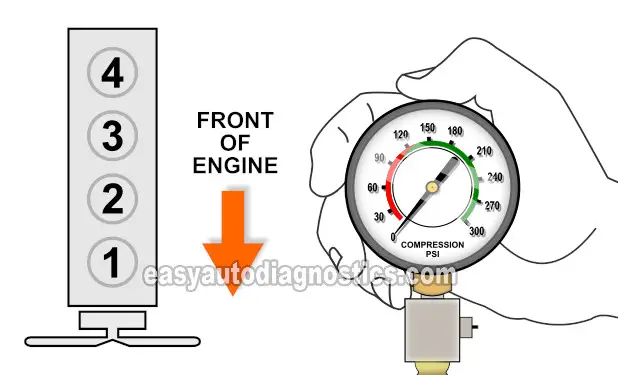

TEST 3: Engine Compression Test

One of the head gasket failures I have seen quite often is the head gasket failing (burning up) in a spot between two side-by-side cylinders.

This type of failure usually causes an engine no-start problem since it causes those two side-by-side cylinders to produce 0 PSI compression.

The way to troubleshoot this type of head gasket failure is to perform an engine compression test, which is the focus of this test section.

NOTE: You can find a comprehensive explanation of the compression test (and how to interpret its results) here:

Let's get going:

- 1

Disable the ignition system.

You can do this by disconnecting the ignition coil/ignition control module from their electrical connectors. - 2

Remove all four spark plugs.

NOTE: Label the spark plug wires with the cylinder number they belong to before disconnecting them from their spark plugs. - 3

Install the compression tester by hand in the spark plug hole of cylinder #1.

Do not use any tools to tighten the compression tester. Hand tightening the compression tester is more than enough to get the proper results. - 4

Have your helper crank the engine.

The needle on the tester will climb as the engine cranks. Once the cylinder reaches its maximum compression the needle will stop climbing. - 5

Once the gauge's needle stops climbing have your helper stop cranking the engine.

- 6

Write down the reading and what cylinder it belongs to (you can use the illustration above to help you identify the cylinder).

- 7

Repeat steps 3 through 6 in the remaining cylinders.

Let's take a look at what your test results mean:

CASE 1: All cylinder compression readings were above 0 PSI. This is the correct and expected test result.

Your next step is to perform a block test with a block tester. For this test go to: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

CASE 2: Two side by side cylinders had 0 PSI compression. This engine compression test result confirms that the head gasket is burned at the point between those two cylinders.

Replace the head gasket.