The manifold absolute pressure (MAP) sensor is not a hard component to test. It can easily be tested with a multimeter -no scan tool required.

Why test it? To make sure it's bad before buying it, especially since quite a few other things can cause the fuel injection computer to think the MAP sensor is bad when it isn't.

In this tutorial, I'm gonna' explain how to test it with a multimeter and a vacuum pump (although the vacuum pump is not an absolute must have to test it).

Contents of this tutorial:

- Symptoms Of A Bad MAP Sensor.

- How The MAP Sensor Works.

- Where To Buy The MAP Sensor And Save.

- TEST 1: Checking The MAP Signal With A Multimeter.

- TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.

- TEST 3: Making Sure The MAP Sensor Is Getting Ground.

- MAP Sensor Code Will Not Go Away.

- More 3.8L V6 GM Tutorials.

![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1995-1999 3.8L V6 Buick, Chevrolet, Pontiac, Olds) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1995-1999 3.8L V6 Buick, Chevrolet, Pontiac, Olds) (at: autotecnico-online.com).

APPLIES TO: This tutorial, on how to test the MAP sensor, applies to the following vehicles:

- 3.8L Buick LeSabre: 1996, 1997, 1998, 1999.

- 3.8L Buick Park Avenue: 1995, 1996, 1997, 1998, 1999.

- 3.8L Buick Regal: 1996, 1997, 1998, 1999.

- 3.8L Buick Riviera: 1995, 1996, 1997.

- 3.8L Chevrolet Lumina: 1998, 1999.

- 3.8L Chevrolet Monte Carlo: 1998, 1999.

- 3.8L Oldsmobile 88 (Eighty-Eight): 1995, 1996, 1997, 1998, 1999

- 3.8L Oldsmobile 98 (Ninety-Eight): 1995, 1996

- 3.8L Oldsmobile Intrigue: 1998, 1999

- 3.8L Oldsmobile LSS: 1996, 1997, 1998, 1999

- 3.8L Oldsmobile Regency: 1997, 1998

- 3.8L Pontiac Bonneville: 1995, 1996, 1997, 1998, 1999

- 3.8L Pontiac Grand Prix: 1997, 1998, 1999

Symptoms Of A Bad MAP Sensor

The MAP sensor's job is to measure the vacuum pressure inside the intake manifold so that the fuel injection computer can calculate engine load.

As such, the MAP is a critical component of the engine management system. Since it's monitored the entire time the engine is running, when it fails you'll see one of the following trouble codes lighting up the check engine light:

- P0107: MAP Sensor Low Voltage.

- P0108: MAP Sensor High Voltage.

- P1106: MAP Sensor Circuit Intermittent High Voltage.

- P1107: MAP Sensor Circuit Intermittent Low Voltage.

You're also gonna' see one or more of the following symptoms:

- Bad gas mileage.

- Black smoke coming out of the tail pipe, especially when you accelerate the vehicle.

- No power and/or hesitation as you accelerate the vehicle. It feels like all of a sudden someone cut the power momentarily as you step on the accelerator pedal.

How The MAP Sensor Works

The following is a basic description of how the manifold absolute pressure (MAP) sensor works. It'll help explain the 'why' of the 3 test this tutorial will help you perform:

- The fuel injection computer supplies 5 Volts and Ground to the MAP sensor.

- At idle the MAP sends the PCM computer a DC voltage signal of about 1.1 to 1.8 Volts.

- When you step on the accelerator pedal to accelerate the engine, vacuum immediately increases which causes the MAP signal voltage to the computer to decrease.

- With this decreasing voltage signal (along with the signal from the CKP sensor, the MAF sensor, the IAT sensor, and the TPS), the computer knows it's time to inject more fuel, advance ignition timing, and a host of other things it has to do to keep your vehicle running optimally.

- As you let go off the accelerator pedal to slow down, the throttle plate closes and of course the MAP sensor sends the info to the computer as it returns to its idle voltage signal, till the whole cycle begins again.

Where To Buy The MAP Sensor And Save

The following links will help you to comparison shop for the MAP sensor of known national brands. You'll avoid buying some knock-off sensor (that may only last a few days) and save a few bucks!:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

If you're not sure if the above MAP sensor fits your particular 3.8L V6 equipped GM vehicle -don't worry. Once you get to the site, they'll make sure the sensor is the right one, if not, they'll find you the right one.

TEST 1: Checking The MAP Signal With A Multimeter

To find out if the MAP sensor is bad, we're gonna' bench test it.

To be a bit more specific, we're gonna' manually apply/release vacuum to it with a vacuum pump and see if its signal voltage decreases/increases.

If the MAP sensor's voltage stays stuck in one value, as you apply/release vacuum to it, then you can conclude that it's bad (after making sure it's getting power and Ground).

If you don't have a vacuum pump, no worries. You can use your mouth to apply vacuum to it (via a vacuum hose).

NOTE: You'll need a multimeter to test your vehicle's MAP sensor. If you don't have one and need to buy one or upgrade yours, the following recommendation will help: Buying A Digital Multimeter For Automotive Diagnostic Testing.

IMPORTANT: The MAP sensor must remain connected to its electrical connector to read its voltage signal. You'll need to use a back-probe on the connector or a wire-piercing probe on the wire to access the MAP signal. You can see an example of this tool here: Wire Piercing Probe Review.

OK, let's start:

- 1

Remove the MAP sensor from the intake manifold. If you had to disconnect the MAP sensor from its electrical connector to remove it, reconnect it now (the MAP sensor must remain connected to its connector for this test).

- 2

Connect the vacuum pump to the MAP sensor's vacuum inlet port.

- 3

Select Volts DC Mode on your multimeter.

- 4

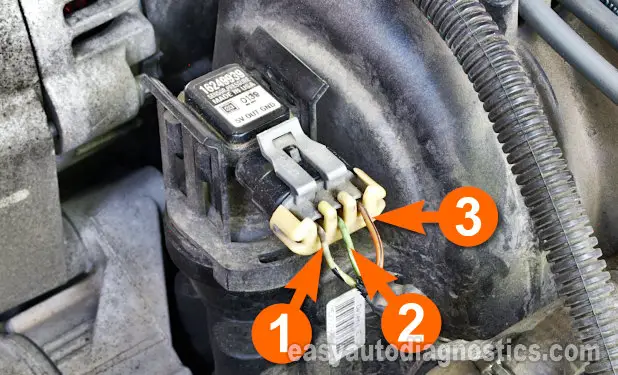

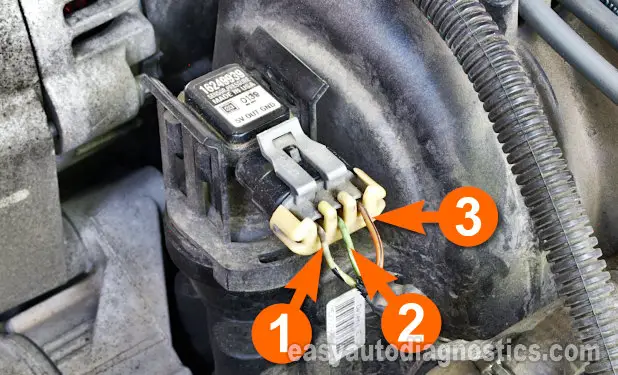

Connect the red multimeter test lead to the middle wire of the MAP sensor's connector.

In the photo above I've identified the middle wire with the number 2.

NOTE: The MAP sensor must remain connected to its electrical connector to test the MAP signal voltage. - 5

Ground the black multimeter test lead on the battery negative (-) terminal.

- 6

Have your helper turn the key On but don't start the engine.

- 7

You should see a voltage around 4.5 Volts DC registering on your multimeter. If it doesn't, don't worry about it just yet, continue with the other steps.

- 8

Apply vacuum to the MAP sensor till the gauge's needle reaches 5 in. Hg of vacuum. These are the approximate readings you should see as you apply vacuum to the sensor:

1.) 0 in. Hg ...... 3-4 Volts.

2.) 5 in. Hg ...... 2.4 Volts.

3.) 10 in. Hg .... 1.9 Volts.

4.) 15 in. Hg .... 1.4 Volts. - 9

Release the vacuum you've applied. The voltage reading should go back up to the value you registered in step 7.

Let's take a look at what your test results mean:

CASE 1: As you applied/released vacuum, the voltage decreased/increased. This is the correct test result.

You can conclude that the manifold absolute pressure (MAP) sensor is working fine and is not defective. No further MAP sensor tests are needed.

Now, if the MAP sensor trouble code won't go away, take a look at the info found at: MAP Sensor Code Won't Go Away for a few more suggestions as to what could be causing the MAP sensor diagnostic trouble code (DTC).

CASE 2: As you applied/released vacuum, the voltage DID NOT decrease/increase. This test result usually confirms that the MAP sensor is fried and that it needs to be replaced. But before you replace it, make sure it's getting 5 Volts and Ground.

The next test is to make sure that the MAP sensor is getting 5 Volts. Go to: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.

CASE 3: The multimeter DID NOT register any voltage. This isn't good, but doesn't condemn the manifold absolute pressure (MAP) sensor as bad yet.

The next test is to make sure that the MAP sensor is getting 5 Volts. Go to: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.