The manifold absolute pressure (MAP) sensor is a critical component of your 1988-1993 4.3L Chevrolet S10 pickup, GMC S15 pickup or GMC Sonoma's engine management system. When the MAP sensor fails, the engine is going to resent it.

In this tutorial, you'll find a straightforward testing guide that'll help you determine if the MAP sensor is good or bad.

And the cool thing is that you don't need any expensive testing equipment to test the MAP sensor.

NOTE: This tutorial applies to both the TBI and CPI fuel injected 4.3L V6 engines.

Contents of this tutorial:

![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1988-1993 4.3L V6 Chevrolet S10 Pickup, GMC S15 Pickup, GMC Sonoma) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1988-1993 4.3L V6 Chevrolet S10 Pickup, GMC S15 Pickup, GMC Sonoma) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 4.3L V6 Chevrolet S10 Pickup: 1988, 1989, 1990, 1991, 1992, 1993.

- 4.3L V6 GMC S15 Pickup: 1988, 1989, 1990.

- 4.3L V6 GMC Sonoma: 1991, 1992, 1993.

Symptoms Of A Bad MAP Sensor

The fuel injection computer on your Chevrolet S10 pickup (GMC S15 pickup, GMC Sonoma) needs to know three things to calculate the amount of air entering the engine.

- Engine load.

- Engine RPMs.

- Intake air temperature.

Once it's calculated the amount of air entering the engine (with this info), it now calculates the correct amount of fuel to inject into the engine.

And as you've guessed it, the component that provides engine load information to the computer is the manifold absolute pressure (MAP) sensor.

When the MAP sensor fails, you'll see one of the following OBD I MAP sensor diagnostic codes illuminating the check engine light:

- Code 33: MAP Sensor Signal Voltage High.

- Code 34: MAP Sensor Signal Voltage Low.

You'll also see one or more of the following symptoms:

- The engine won't start.

- The engine takes a long time to start (extended cranking time).

- Black smoke coming out of the tailpipe.

- Bad gas mileage.

- The engine idles rough when running.

- A lack of power when under load.

Where To Buy The MAP Sensor And Save

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

Not sure if the MAP sensor fits your vehicle? Don't worry. Once you get to the site, they'll make sure it fits by asking you the specifics of your vehicle. If it doesn't fit, they'll find you the right MAP sensor.

MAP Sensor Circuit Descriptions

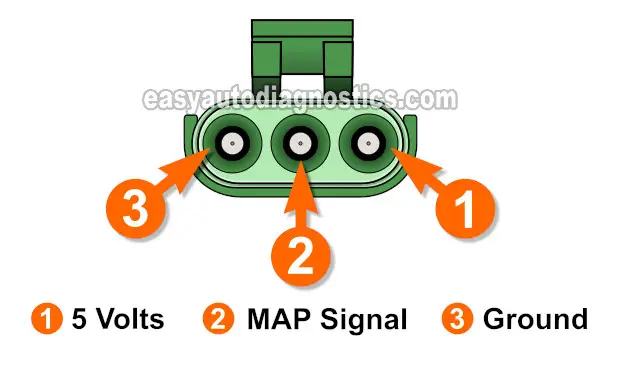

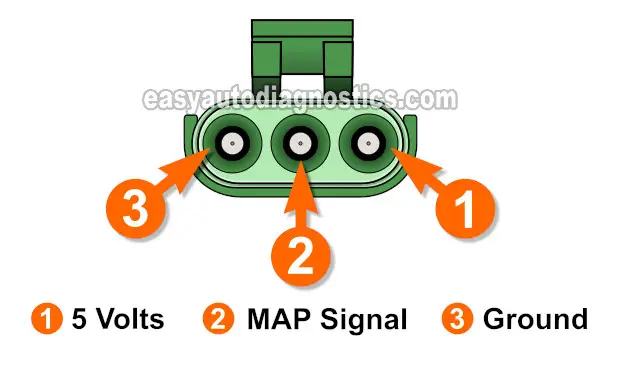

The MAP sensor's electrical connector has three wires coming out of it and each one has a specific job to do.

The following table has a brief description of what each wire does:

| Wire | Color | Description |

|---|---|---|

| 1 | Grey (GRY) | 5 Volts |

| 2 | Light green (LT GRN) | MAP signal |

| 3 | Purple (PPL) or Black With Red Stripe (BLK/RED) | Ground |

TEST 1: Testing The MAP Sensor Signal

The very first thing that we're going to do to determine if the MAP sensor is good or bad, is to check its output voltage signal.

If the MAP sensor is OK, its output voltage signal will decrease when we apply vacuum to the sensor.

If we release the vacuum we applied to the sensor, its voltage signal should rise back to its original (no vacuum) value.

When we apply/release vacuum to the MAP sensor, we'll have a multimeter connected to its output signal wire and observe the changes in its voltage reading.

Don't worry, this is a fairly simple test that will let you know right away whether the MAP sensor is working properly or not.

NOTE: If you don't have a vacuum pump, don't worry. You can use your mouth to apply vacuum to the MAP sensor.

IMPORTANT: The MAP sensor must remain connected to its electrical connector to read the voltage within its signal wire. You'll need to use a back probe on the connector or a wire piercing probe on wire. You can see an example of this tool here: Wire Piercing Probe.

OK, let's get started:

- 1

Remove the MAP sensor from its place on the intake manifold.

- 2

If you had to disconnect the MAP sensor from its electrical connector to remove it, reconnect it to the connector now.

- 3

Connect your vacuum pump to the MAP sensor's vacuum inlet.

You'll need to use a piece of vacuum hose to connect the vacuum pump to the MAP sensor. - 4

Place your multimeter in Volts DC mode.

- 5

Connect the red multimeter probe to the wire that connects to the terminal labeled with the number 2 (in the image above).

This wire should be the light green (LT GRN) wire of the connector.

IMPORTANT: The MAP sensor must remain connected to its 3-wire connector. - 6

Connect the black multimeter test lead directly to the battery negative (-) terminal.

- 7

Turn the key ON but don't start the engine.

- 8

At this point your multimeter should register a value around 4.5 Volts DC.

- 9

Now, pump the vacuum pump to apply vacuum to the MAP sensor. The voltage should decrease.

- 10

Release the vacuum you applied to the MAP sensor. The voltage should increase.

OK, let's take a look at what your test results mean:

CASE 1: The MAP voltage signal decreased/increased as you applied/released vacuum to the sensor. This is the correct result and confirms that the MAP sensor is functioning correctly.

If a MAP sensor diagnostic trouble code keeps illuminating the check engine light, you can conclude the MAP sensor itself is not the cause. For more info, take a look at the section: MAP Sensor Code Won't Go Away.

CASE 2: The MAP voltage signal DID NOT increase/decrease as you applied/released vacuum. This test result usually indicates that the MAP sensor is bad.

Before replacing the MAP sensor, you need to make sure that it's getting power and Ground. Go to the next test: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.

CASE 3: Your multimeter registered 0 Volts. This test result generally tells you that the MAP sensor is bad.

Before replacing the MAP sensor, you need to make sure that it's getting power and Ground. Go to the next test: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.