Testing the engine compression on the 4.0L Jeep Cherokee and Wrangler is not difficult (especially since the spark plugs are easy to remove).

In this tutorial, I'm gonna' explain how to do an engine compression test and how to interpret its test results.

You'll be able to find out if an engine compression problem is behind a misfire or an 'engine no-start' problem.

Contents of this tutorial:

![]() You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (1993-2001 4.0L Jeep Cherokee) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (1993-2001 4.0L Jeep Cherokee) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 4.0L Jeep Cherokee: 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001.

- 4.0L Jeep Wrangler: 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001.

Symptoms Of Low Or No Engine Cylinder Compression

If the engine starts and runs, in your 4.0L Jeep Cherokee or Wrangler, a compression problem will cause a misfire or a rough idle condition.

If your Jeep is OBD II equipped, you'll see one or more of the following misfire trouble codes lighting up the check engine light:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

Besides a cylinder misfire condition (or a rough idle condition), you'll see one or more of the following symptoms:

- Bad gas mileage.

- You're also gonna' notice a heavier exhaust smell coming out of its tailpipe.

- Blue smoke coming out of the tail-pipe.

- The engine is not as peppy as it was once.

If the compression problem is affecting all 6 cylinders (as in 0 PSI compression in all of them), then the engine is not gonna' start.

Important Tips And Suggestions

TIP 1: If the engine in your 4.0L Jeep Cherokee (Wrangler) has been running for any length of time, let it cool down completely before the spark plugs are removed.

Removing the spark plugs from a hot engine can result in damage to the spark plug hole threads.

One method that I have used to cool the engine down in a matter of 15-20 minutes is placing a box fan on top of it to cool it down.

TIP 2: The engine has to be cranked to test the compression, for this reason take all necessary safety precautions while working around the engine when it's being cranked.

TIP 3: Have your helper wait outside of the vehicle till you're done setting up the test.

This way you'll avoid having your helper accidentally crank the engine while you're installing the compression tester.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make some recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Finding The Dead Cylinders

To get started, we'll test the compression of all six cylinders.

If you don't have an engine compression tester, you can run down to your local auto parts store and buy one (or rent one) from them.

If you'd like to save a few bucks on its purchase, check out my recommendations here: Which Compression Tester Should I Buy?

These are the test steps:

- 1

Disable the ignition system by disconnecting the ignition coil from its electrical connector.

This will prevent the ignition coil from sparking during the test. - 2

Remove the spark plugs. The engine must be cold before removing them.

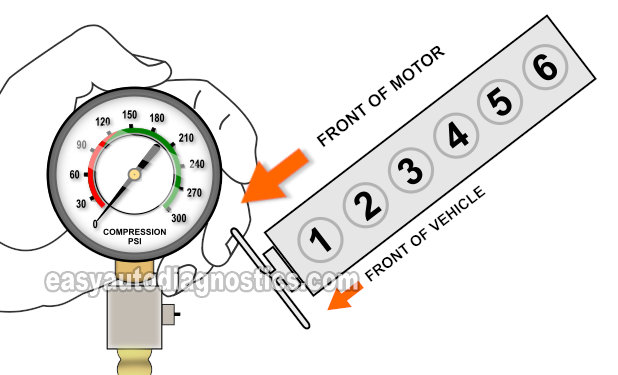

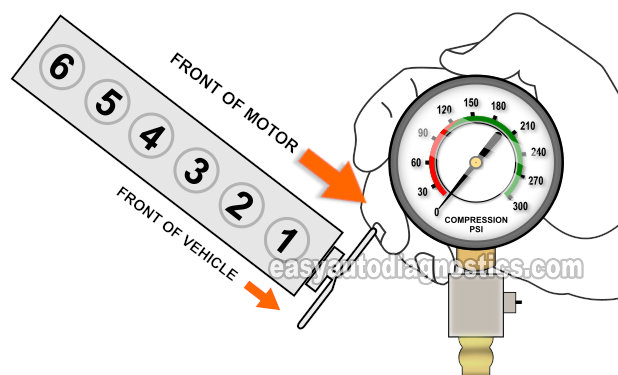

When removing the spark plugs, be careful not to drop any of them on the floor, or you run the risk of having the spark plug's porcelain insulator crack and then you'll have a misfire on your hands. - 3

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 4

Have your helper crank the engine till the needle on the compression gauge stops climbing.

- 5

Record on paper the value at which the needle stopped and the number of the engine cylinder on a piece of paper.

Release the pressure on the gauge and repeat this step one more time. - 6

Repeat steps 3 through 5 on the remaining cylinders.

Let's examine your test results:

CASE 1: All 6 cylinders had 0 PSI. This test result tells you that the engine has an internal mechanical problem.

The most common cause of this condition is a broken timing chain or a blown head gasket.

Your next step should be to check the condition of the timing chain and head gasket.

CASE 2: One or more cylinders had a low compression value compared to the others. This could be normal or it could be causing a problem.

To find out if the compression values are normal or not, go to: Interpreting The Compression Test Results.

CASE 3: All 6 compression values were similar and above 120 PSI. This lets you know that a compression problem is not behind the no-start or misfire problem you're trying to troubleshoot.

Interpreting The Compression Test Results

The engine cylinders usually wear out at the same rate, unless they have suffered some sort of mechanical problem.

If the compression values vary too much, the engine will suffer a rough idle or a misfire problem that will light up the check engine light with a misfire trouble code.

The key to finding out is to do some math and see if the lowest compression value you got differs by more than 15% of the highest value.

You can do this by using my online low compression calculator here: Online Low Engine Compression Calculator or, as I mentioned before, by calculating this 15% difference manually.

To explain how to figure out this 15% thing manually, let's say that I got the following compression test results from a 4.0L Jeep Cherokee (Wrangler):

- Cylinder #1 175 PSI.

- Cylinder #2 165 PSI.

- Cylinder #3 170 PSI.

- Cylinder #4 120 PSI.

- Cylinder #5 160 PSI.

- Cylinder #6 170 PSI.

My next step is to do the following calculation:

- I'll multiply 0.15 (15%) by the highest value: 175 x 0.15. This gives me 26.25, but I'll round it out to 26.

- Next, I subtract 26 from 175: 175 - 26 = 144.

- So now I know that the lowest possible compression value the engine can have is: 144 PSI.

This means that cylinder #4, which has a compression value of 120 PSI, is the one causing the misfire because it's below the 144 PSI minimum.

To find out if the compression values you got from your engine compression test are good or bad, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

TEST 2: Wet Engine Compression Test

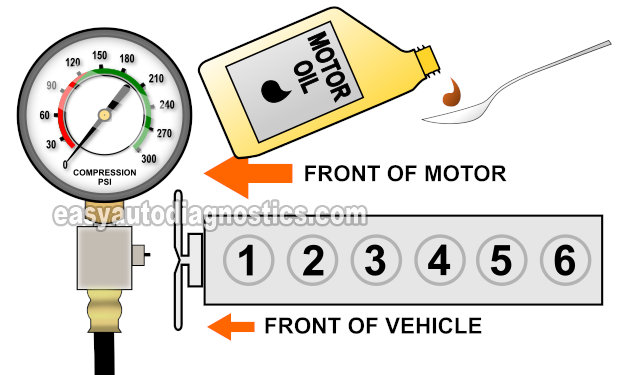

If in TEST 1 you got one or more compression values that are lower than the rest, then your next is to do a 'wet' compression test.

All that's involved is adding about 2 tablespoons of engine oil to the cylinder with low or 0 PSI compression. Then the cylinder's compression is tested again.

If the compression value increases, from the value you got in TEST 1, then you can conclude that the low compression problem of that cylinder is due to bad piston rings.

If the compression value does not increase, then you can conclude that that cylinder's compression problem is due to bad or damaged cylinder head valves.

These are the test steps:

- 1

Add 1 or 2 tablespoon of engine oil in the cylinder you need to retest. I suggest using a small and long funnel so that the oil will reach the inside of the cylinder.

- 2

Install the compression gauge on the cylinder you just added oil to.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

Repeat steps 1 thru' 4 on any other cylinder you need to check.

Let's examine your test results:

CASE 1: The compression value increased. This test result tells you that the low or near 0 PSI compression value is due to worn out piston rings of that specific cylinder.

CASE 2: The compression value DID NOT increase. This test result confirms that the cylinder head valves of that cylinder are worn-out or damaged.

More 4.0L Jeep Cherokee Tutorials

You can find a complete list of diagnostic tutorials and wiring diagrams for the 4.0L Jeep Cherokee here:

Here's a sample of the tutorials you'll find in the index:

- Ignition System Wiring Diagram (1993-1995 4.0L Jeep Cherokee)

- How To Test For A Blown Head Gasket (1993-2001 4.0L Jeep Cherokee)

- How To Test The Crankshaft Position Sensor Jeep 4.0L (1993-1995 4.0L Jeep Cherokee)

- How To Test The Front O2 Sensor Heater (1996 4.0L Jeep Cherokee)

If this info saved the day, buy me a beer!