OK, you're here because you got a no spark result on your spark tester. And before you condemn the coil pack to the trash, the Switching signal has to be checked. For this part you can use an LED light, which is my recommendation or a test light will do.

I prefer the LED light because it's a much safer alternative than using the test light to test the Switching signal circuit.

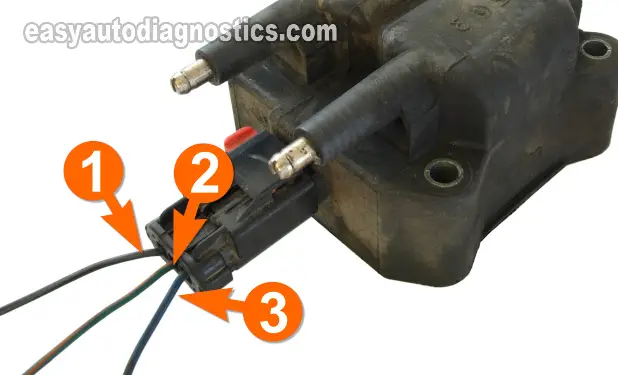

As already stated, this car's coil pack is two ignition coils in one package. The connector has three wires and here are their basic circuit descriptions (the arrow in the photo points to the front of the vehicle):

- One will be the power circuit (12 Volts). This circuit feeds both coils inside the coil pack. In the photo this is circuit number 2.

- One will be the Switching signal circuit for the coil that fires the #2 and #3 cylinders. In the photo this is circuit number 1.

- The last remaining wire is the Switching signal circuit for the coil that fires the #1 and #4 cylinders. In the photo this is circuit number 3.

Simple enough, no? Now comes the test. Some words of caution, tho'. If you insert anything into the female terminal of the connector, you must:

- Make sure that it won't damage it! Don't insert something that is thicker or bigger than the male spade terminal that goes into it.

- If you don't take this precaution you'll open up the female terminal in the connector. If this happens you'll have an intermittent false contact between both terminals when you reconnect the connector to the ignition coil pack. This is a headache you don't want to give yourself. So be careful.

Testing For 12 Volts

OK, enough already with the precautions and disclaimers, let's get to testing:

- With the ignition coil pack connected or not, it doesn't matter.

- Put your multimeter in Volts DC mode.

- Probe the power circuit of the connector with the RED test lead of the multimeter and an appropriate tool (I recommend a wire piercing probe).

- This is Circuit 2 shown in the photo.

- Connect the black multimeter test lead to the battery Ground terminal.

- Have your assistant crank the engine.

- You should see the multimeter registering 12 Volts the whole time the engine is cranking.

If the multimeter showed the 12 Volts, all is good and you can continue to the next step. If you didn't get the 12 Volts, recheck all of your connections and redo the test. If you still have no voltage, then the coil pack is not the source of the problem.

The mostly likely cause will be that the fuse that feeds it this voltage is blown, or if it's a relay, it's bad. On this particular make, if the fuel injection computer does not see a crankshaft position signal, it will not activate the relay that supplies the ignition coil with voltage.

On your specific make and model, you'll have to consult your service manual to find out from where and what the coil pack gets juice from.

Testing For The Switching Signal

After verifying that the coil pack is indeed receiving 12 Volts, now we gotta' check to see see that it's also getting the Switching signal.

As you already know, this signal comes from the ignition control module. Which in this case is in the fuel injection computer.

In the photo, the Circuit number 1 fires the #2 and #3 cylinders. The circuit number 3 fires the #1 and #4 cylinders.

- Disconnect the coil pack from its connector.

- Insert the red lead of the LED to the power circuit of the connector (circuit number 2).

- Insert the black lead of the LED to any of the two remaining terminals.

- Have your assistant crank the engine.

- After observing whatever result you get from the LED light, test the remaining circuit.

- So, leaving the red LED lead in its place, remove the black one from where you originally inserted it and reinsert it in the remaining terminal.

- Have your assistant crank the engine once again.

- Observe the result.

IMPORTANT The LED is polarity specific, meaning that it will only work with its RED lead in the power circuit of the ignition coil's connector. This LED light you can buy at your local Radio Shack. To see an example of one click here LED Test Tool.

Interpreting The Results

Keeping in mind that we have reached this point because one of the towers of the coil pack or the entire coil pack is not sparking, lets interpret the results of the above test.

- If the LED light flashed in both circuits: Then the Switching signal is present and the coil is bad.

- If the LED light flashed in one circuit only: Then the Circuit that did not make the LED flash has an electrical open in it. Something in the circuit between the coil pack and the computer has fried. Or the computer is fried.

- If the LED light stayed lit continuously (did not flash) in one or both circuits, then there is a short to Ground in the circuit between the coil pack and the computer. Or the computer is fried.