A failed crankshaft position sensor will cause your 3.0L Mitsubishi Montero to crank but not start. Fortunately, you can test the crank sensor with a simple multimeter to find out if it's good or bad.

In this tutorial, I'll show you just how in a simple step-by-step way.

Contents of this tutorial:

- Symptoms Of A Bad Crankshaft Position Sensor.

- What Tools Do I Need?

- Circuit Descriptions Of The Crankshaft Position Sensor.

- Basic Operating Theory.

- Where To Buy The Crank Sensor And Save.

- TEST 1: Verifying The Crank Sensor Is Getting Power.

- TEST 2: Verifying The Crank Sensor Is Getting Ground.

- TEST 3: Verifying The Crank Sensor Is Creating A Crankshaft Position Signal.

- More 3.0L Mitsubishi Tutorials.

![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor De La Posición Del Cigüeñal (1997, 1998 3.0L Mitsubishi Montero) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor De La Posición Del Cigüeñal (1997, 1998 3.0L Mitsubishi Montero) (at: autotecnico-online.com).

Symptoms Of A Bad Crankshaft Position Sensor

When the crankshaft position sensor on your 3.0L Mitsubishi Montero fails, your engine won't start. Here are some more specific symptoms:

- The vehicle will not start. The engine will turn over (crank) but won't start.

- Trouble code lighting up the check engine light (CEL) on your instrument cluster.

- P0335: Crankshaft Position (CKP) Sensor Circuit Malfunction.

- No fuel injector pulses (as checked with a Noid light).

- No spark at any of the spark plug wires (as checked with a spark tester).

Although your Montero's PCM is designed to register a crank sensor trouble code when the crank sensor fail, it rarely does. This is why it's a good idea to test the crank sensor with a multimeter to see if it's behind your 'cranks but does not start' condition.

What Tools Do I Need?

Testing the crankshaft position sensor on your Mitsubishi Montero doesn't require any expensive testing equipment or expensive tools. As mentioned at the beginning of the tutorial, you don't need a scan tool.

These are the specific tools you'll need:

- A multimeter.

- Don't have a digital multimeter that can read Hertz frequency? Click here to see my recommendations: Buying A Digital Multimeter For Automotive Diagnostic Testing.

- A wire piercing probe.

- This tool is a handy tool to have. To see what it looks like, go to: Wire Piercing Probe.

- Hand tools to turn the crankshaft pulley by hand.

To get the most accurate test result, you'll need to turn the engine by hand and not with the starter motor.

Circuit Descriptions Of The Crankshaft Position Sensor

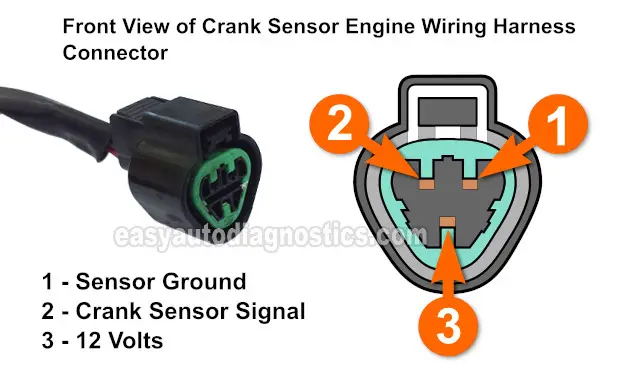

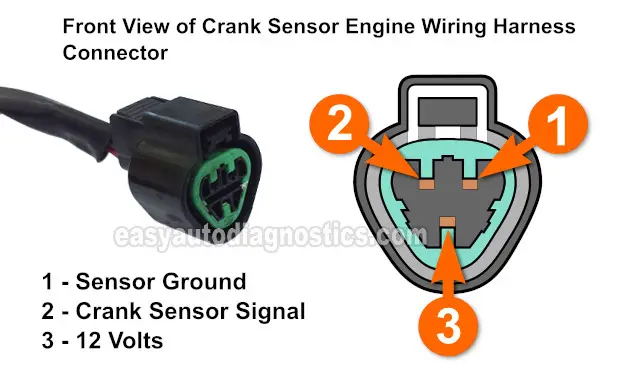

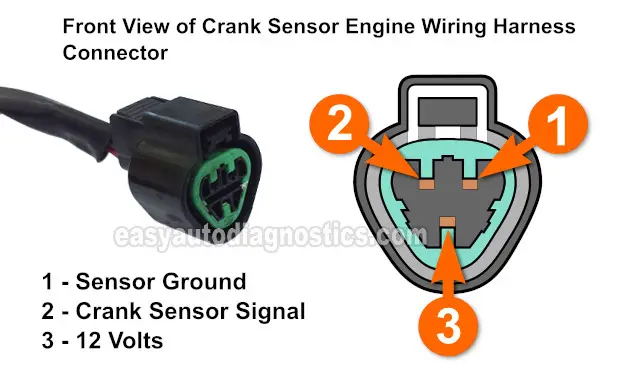

The crankshaft position sensor, on your 3.0L Mitsubishi Montero, is a three wire Hall Effect type sensor that can be easily tested with a multimeter. Below are the circuit descriptions that you'll need in the tests presented in this tutorial:

- Circuit labeled 1:

- Ground Circuit (provided by PCM).

- Circuit labeled 2:

- Crankshaft position signal (output to the PCM).

- Circuit labeled 3:

- Power circuit (12 Volts).

The crankshaft position (CKP) sensor is located behind the timing belt and it can be tested without removing the timing belt or its components. This is due to the fact that the crankshaft position sensor's connector is located on top of the engine and in plain view (next to the ignition control module). In the photo below, the orange arrow points to the location of the crankshaft position sensor connector (the photo applies to: 3.0L 1997-2004 Montero Sport).

Basic Operating Theory

The crankshaft position sensor is one of many key components your 3.0L Mitsubishi Montero's ignition system needs to start and keep the engine running. In a nutshell, this is how the crank sensor fits into the ignition system 'scheme of things':

- As you turn the key and crank the engine. The crankshaft position sensor gets power and Ground. With power and Ground supplied, the engine rotation induces the crankshaft position sensor to start producing a crankshaft position signal.

- This crankshaft position signal is sent to the PCM, upon being received by the PCM along with other necessary sensor information, starts to do its little song and dance and sends back a Triggering Signal to the ignition power transistor (ignition control module).

- This Triggering Signal contains the instructions for the ignition power transistor (ignition control module) to start firing the ignition coils in the correct firing order.

- Each ignition coil then fires spark to two different cylinders at the exact same time (in what's known as the Waste Spark method).

- One cylinder is fed spark directly by the ignition coil.

- The other cylinder is fed spark thru' a spark plug wire (high tension wire).

- With fuel being injected, your 3.0L Mitsubishi Montero's engine starts and stays running.

Where To Buy The Crank Sensor And Save

The following links will help you comparison shop for the crankshaft position sensor.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

Not sure if the above crankshaft position sensor fits your particular 3.0L Mitsubishi Montero? Don't worry, once you get to the site, they'll make sure it fits. If it doesn't fit, they'll find you the right one.

TEST 1: Verifying The Crank Sensor Is Getting Power

The first thing we want to do to find out if the crankshaft position sensor is bad (or not) is to make sure it's getting power.

This power is in the form of battery voltage (12 Volts DC) and is supplied by the RED wire that connects to connector terminal labeled with the number 3 in the illustration above.

NOTE: Avoid probing the front of the female terminal (of the connector) with the multimeter's test lead (or you run the risk of damaging the female terminal). My suggestion to you is to use a back-probe or a wire-piercing probe to test for this voltage.

Here are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

Disconnect the crankshaft position sensor from the engine wiring harness connector.

IMPORTANT: This test is done on the engine wiring harness crank sensor connector and NOT on the sensor's connector. You can further identify the engine wiring harness connector by the fact that it has female terminals. - 3

Connect the red multimeter test lead to the RED wire of the crank sensor's engine wiring harness connector using an appropriate tool.

The RED wire connects to the terminal labeled with the #3 in the illustration above. - 4

Connect the black multimeter test lead to the battery negative (-) terminal.

- 5

Have your assistant turn the key to the ON position but without cranking the engine.

- 6

Your multimeter should register 10 to 12 Volts if the RED wire is feeding the crankshaft position sensor with power.

Let's interpret your test results:

CASE 1: The multimeter showed 10 to 12 Volts. This is the correct test result and lets you know all is good in this circuit and the CKP sensor is getting power.

The next step is to make sure its Ground circuit is OK too, go to: TEST 2: Verifying The Crank Sensor Is Getting Ground.

CASE 2: The multimeter DID NOT show 10 to 12 Volts. This indicates that the CKP sensor is not getting power. Without 10 to 12 Volts, the CKP sensor will not work and your Mitsubishi vehicle will 'crank but not start'.

Although it's beyond the scope of this tutorial, your next step is to find out why this voltage is missing and restore it to solve your Montero's no-start condition.