TEST 2: Verifying The Crank Sensor Is Getting Ground

So far, you've confirmed that the crankshaft position sensor is getting power (TEST 1). Now we need to make sure that it's getting Ground.

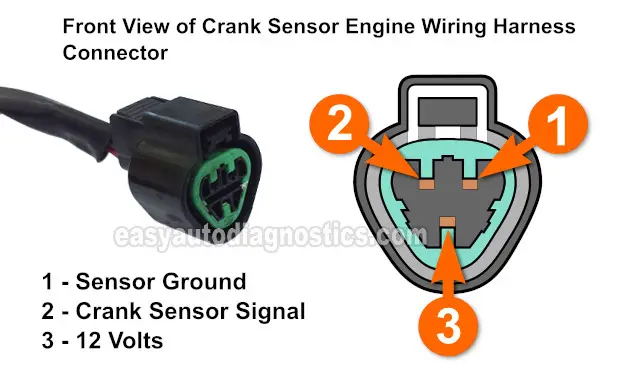

The wire that feeds this Ground to the crank sensor is the black (BLK) wire of the engine wiring harness crank sensor connector. This wire connects to the terminal labeled with the number 1 in the illustration above.

NOTE: Avoid probing the front of the female terminal (of the connector) with the multimeter's test lead (or you run the risk of damaging the female terminal). My suggestion to you is to use a back-probe or a wire-piercing probe to test for the presence of Ground in the wire.

This is what you need to do:

- 1

Place your multimeter in Volts DC mode.

- 2

Disconnect the crankshaft position sensor from the engine wiring harness connector.

IMPORTANT: This test is done on the engine wiring harness crank sensor connector and NOT on the sensor's connector. You can further identify the engine wiring harness connector by the fact that it has female terminals. - 3

Connect the black multimeter test lead to the BLK wire of the crank sensor connector. This is the wire that connects to the female terminal identified with the number 1 in the illustration above.

- 4

Connect the red multimeter test lead directly on the battery's positive (+) terminal.

- 5

Your multimeter should register 12 Volts with or without the Key in the ON position (if the BLK wire is feeding the crank sensor with Ground).

Let's interpret your test results:

CASE 1: The multimeter showed 10 to 12 Volts. This is the correct test result and confirms all is good in this circuit and the CKP sensor is getting Ground.

The next step is check that the crank sensor is creating a crankshaft position signal, go to: TEST 3: Verifying The Crank Sensor Is Creating A Crankshaft Position Signal.

CASE 2: The multimeter DID NOT show 10 to 12 Volts. This indicates that the CKP sensor is not getting Ground. Without Ground, the CKP sensor will not work and your Mitsubishi Montero will 'crank but not start'.

Altho' it's beyond the scope of this tutorial, your next step is to find out why this Ground is missing and restore it. Repairing the cause of this missing Ground should solve your vehicle's no-start problem.

TEST 3: Verifying The Crank Sensor Is Creating A Crankshaft Position Signal

If you've reached this point, you have confirmed that the crankshaft position sensor on your Montero is getting both power and Ground. The next and last step is to see if it's creating a crankshaft position signal.

This is another multimeter test but with a major difference: you have to manually turn the engine to get the crank sensor to create a crankshaft position voltage signal. For this test you should NOT use the starter motor to crank the engine.

Why turn the engine over by hand? Because turning the engine over with a socket and ratchet wrench will ensure the accuracy of the crank sensor test with a multimeter. Testing the crank sensor by having the starter crank the engine will not give you an accurate test result.

IMPORTANT: The crankshaft position sensor must remain connected to its electrical connector in order to read the CKP signal. To access the signal inside the wire, you will need to use a back probe on the connector or a wire piercing probe on the cable. You can see an example of this tool here: Wire Piercing Probe.

These are the steps:

- 1

Disable all of the ignition coils by disconnecting them from their electrical connectors, this is important!

- 2

Place your multimeter in Volts DC mode.

- 3

Reconnect the crankshaft position sensor to its electrical connector.

- 4

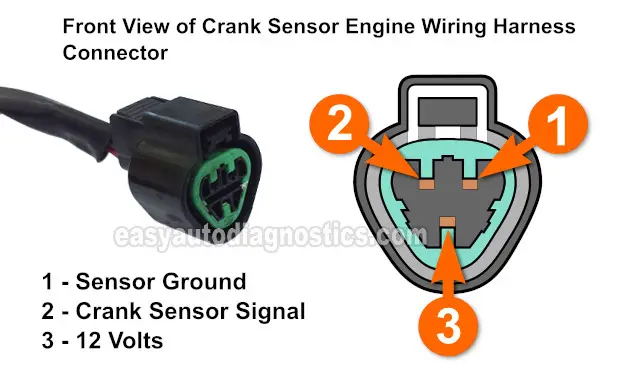

Connect the red multimeter test lead to the BLU wire with an appropriate tool. The BLU wire connects to the connector terminal identified with the number 2 in the illustration.

You should use a back-probe or a wire-piercing tool to attach to your multimeter to check for this crankshaft position signal (Wire Piercing Probe). - 5

Connect the black multimeter test lead directly on the battery's negative (-) terminal.

- 6

Turn the key to the ON position but don't crank the engine. This will power up the crank sensor.

- 7

With an appropriate tool, turn the crankshaft pulley by hand. Do not crank the engine with the key from inside of the vehicle.

- 8

If the crankshaft position sensor is functioning correctly, your multimeter will register an ON/OFF voltage signal as you crank the engine by hand. 'On' will register 5 Volts on the multimeter and 'Off' will register 0.1 Volts.

Let's find out what your test results mean:

CASE 1: The multimeter registered the ON/OFF voltage values the whole time you turned the engine by hand. This is the correct test result and tells you that the crankshaft position sensor is working and is not the cause of your Mitsubishi Montero's 'no-spark no-start' condition.

CASE 2: The multimeter DID NOT register the ON/OFF voltage values as you turned the engine by hand. This test result tells you that the crankshaft position sensor is bad and needs to be replaced if you have:

- Checked/confirmed that the crankshaft position sensor is being fed power on the RED wire (TEST 1).

- Checked/confirmed that the crankshaft position sensor is being fed Ground on the BLK wire (TEST 2).

- In this test step, you confirmed that the sensor is not creating the ON/OFF voltage signal (On= 5 Volts, Off= 0.1 Volts).

So, taking these 3 specific test results into account, you can conclude the crankshaft position sensor on your 3.0L Mitsubishi Montero is bad.

More 3.0L Mitsubishi Tutorials

You can find a complete list of 3.0L Mitsubishi tutorials here: Mitsubishi 3.0L Index Of Articles.

Here's a small sample of the tutorials you'll find in the index:

- How To Test Engine Compression (3.0L Mitsubishi).

- How To Test The MAF Sensor (1997, 1998 3.0L Mitsubishi Montero).

- How To Test The Throttle Position Sensor (3.0L Mitsubishi Montero).

- Testing The Power Transistor, Ignition Coil, and Crank Sensor.

- How To Bench Test A Starter Motor (Step By Step).

If this info saved the day, buy me a beer!