The 2002-2003 3.5L Nissan Maxima has 2 camshaft position sensors and both can be easily tested with a multimeter.

In this tutorial, I'll show you how in a step-by-step manner.

Contents of this tutorial:

- Symptoms Of A Defective Camshaft Position Sensor.

- Circuit Descriptions Of The Camshaft Position Sensor.

- Where To Buy The Camshaft Position Sensor.

- TEST 1: Checking The Camshaft Position Signal With A Multimeter.

- TEST 2: Making Sure The Cam Sensor Is Getting Power.

- TEST 3: Making Sure The Cam Sensor Is Getting Ground.

- Oscilloscope Waveforms Bank 1 And Bank 2 Cam Sensors.

- Cam Sensor Bank 1 And Bank 2 Wiring Diagram.

Symptoms Of A Defective Camshaft Position Sensor

Here is a basic list of the symptoms you are going to see when the camshaft position sensor fails on your 2002-2003 3.5L Nissan Maxima.

- A trouble code P0340: Camshaft Position Sensor 1 Circuit lighting up the check engine light.

- A trouble code P0345: Camshaft Position Sensor 2 Circuit lighting up the check engine light.

- Car cranks but does not start.

- Car runs, but stalls.

Circuit Descriptions Of The Camshaft Position Sensor

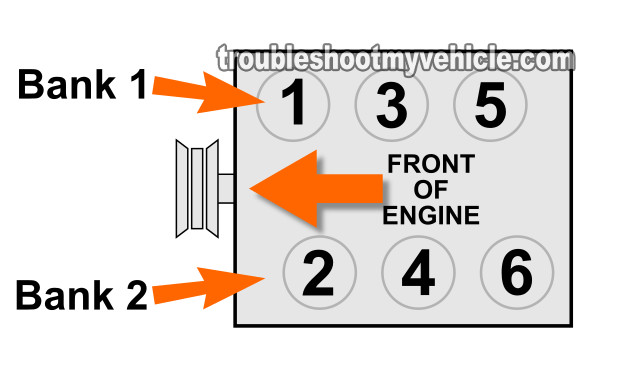

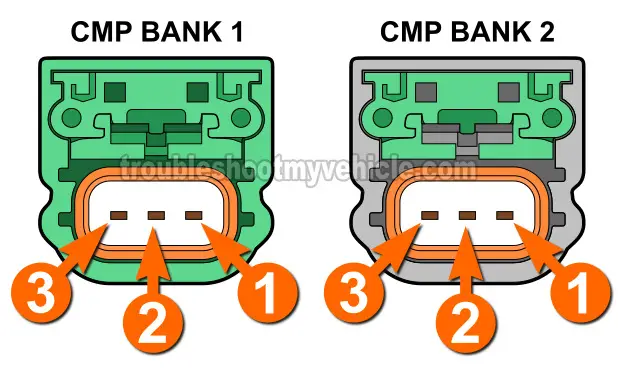

Your 3.5L Nissan Maxima comes equipped with 2 camshaft position sensors. They're identified by the bank of cylinders that they are on.

The Camshaft Position Sensor Bank 1 is on the cylinder head that over cylinders 1, 3, and 5. This bank of cylinders is on the firewall side of the engine.

The Camshaft Position Sensor Bank 2 is on the cylinder head that over cylinders 2, 4, and 6. This bank of cylinders is on the radiator side of the engine.

Both sensors work in the exact same manner and are tested in the same manner.

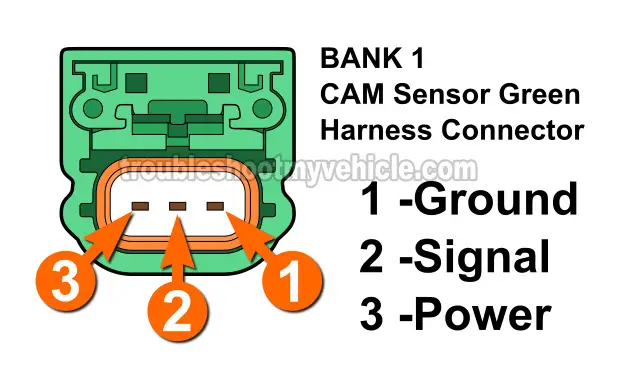

| Cam Position Sensor Bank 1 | ||

|---|---|---|

| Terminal | Wire | Description |

| 1 | BLK | Ground |

| 2 | RED | Camshaft Position Signal |

| 3 | WHT | Power -12 Volts |

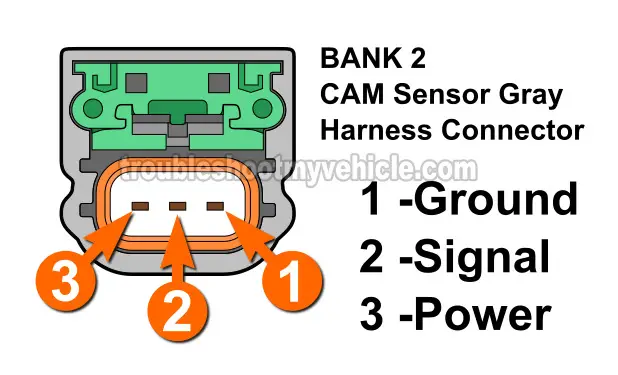

| Cam Position Sensor Bank 2 | ||

|---|---|---|

| Terminal | Wire | Description |

| 1 | BLK | Ground |

| 2 | RED | Camshaft Position Signal |

| 3 | WHT | Power -12 Volts |

Where To Buy The Camshaft Position Sensor

You can buy the camshaft position sensor at your local auto parts store or if you're like me and need to save money on any kind of purchase, you can buy it online.

The Hitachi CPS0001 Camshaft Position Sensor listed below is the original factory part for the 2002-2002-2003 3.5L Nissan Maxima.

You can check it out here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Checking The Camshaft Position Signal With A Multimeter

As the engine turns, the camshaft position sensor produces an ON/OFF signal that can be measured with a multimeter (oscilloscope too).

The get an accurate test result, you'll need to turn the engine by hand. Don't use the starter motor to crank the engine.

You can manually turn the engine by using a 1/2 inch ratchet and appropriate socket on the crankshaft pulley.

NOTE: The instructions below apply to either bank 1 or bank 2 cam sensor.

Oscilloscope: If you're using one of these bad boys, you can crank and start the engine to observe the waveforms. You can see the waveforms I recorded here: Oscilloscope Waveforms Bank 1 And Bank 2 Cam Sensors.

OK, let's get started:

- 1

Raise the front passenger side of your Maxima onto a jack stand (for safety).

Remove the front passenger side wheel and remove the plastic water splash guard (shield) that protects the crankshaft pulley and serpentine belt from water. - 2

Disconnect the cam sensor from its electrical connector. As a safety precaution, disconnect all of the ignition coils from their electrical connectors.

- 3

Connect the red multimeter test lead to the red wire of the camshaft position sensor's connector. You'll need to use a tool like a wire piercing probe to connect the red test lead to the red wire.

You can see a what a wire piercing probe looks like here: Wire Piercing Probe. - 4

Connect the connector back to the camshaft position sensor. The camshaft position sensor must be connected to its electrical connector for this test to work.

- 5

Set your multimeter to Volts DC mode and Ground the black multimeter test lead directly on the battery negative (-) terminal.

- 6

Slowly turn the crankshaft pulley by hand in a clock-wise direction while you keep you eyes on the multimeter once you have the multimeter set up. Do not use the starter motor to crank the engine and I want to emphasize slowly turning the crank pulley.

- 7

If the camshaft position sensor is working correctly, the multimeter will register an ON/OFF voltage of 9-10 and 0 Volts DC as you manually turn the crankshaft. Off is when the multimeter displays 9.5 - 10 Volts DC and On is 0 Volts DC.

To be a little more specific: your multimeter will register 9 to 10 Volts most of the time you're turning the crank pulley. When the camshaft position sensor is activated (and if it's working correctly) by the pole piece on the camshaft, then this voltage will go down to 0 Volts.

Let's take a look at what your test results mean:

CASE 1: The multimeter registered 9.5 to 10 Volts DC and the 0 Volt pulse as the engine turned. This is the correct and expected test result and tells you that the cam sensor you're testing is functioning correctly.

CASE 2: The multimeter DID NOT register the ON/OFF 9.5 to 10 Volts DC and 0 Volts pulse as you manually turned the crankshaft pulley. This result indicates that the camshaft position sensor is not creating a signal.

The next step is to verify that it's getting power (12 Volts). For this test, go to: TEST 2: Making Sure The Cam Sensor Is Getting Power.