Interpreting The Results Of The Engine Compression Test

It's not uncommon to find that the compression values differ among engine cylinders (especially on high mileage engines). Up to a certain point, this difference doesn't affect engine performance at all.

It's when these cylinder compression values vary too much that you're gonna have a problem on your hands. The cool thing is that we can find out if the low compression values are causing a problem (with that cylinder or cylinders) or not.

The rule of thumb is that they can not vary more than 15% from each other and if they do, you're gonna' have a genuine misfire condition on your hands or possibly a no-start condition (if more than one cylinder is affected).

How do you figure this out? You can find out by using my online low compression calculator here: Online Low Engine Compression Calculator or manually this way:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

To make better sense of the above calculation, let's say that I got the following compression test results:

| Cylinder | Pressure |

|---|---|

| #1 | 175 PSI |

| #2 | 170 PSI |

| #3 | 165 PSI |

| #4 | 120 PSI |

The next step is to do the math:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26.

- STEP 2: 175 - 26= 149.

- ANSWER: 149 PSI is the lowest possible compression value.

Since cylinder #4 is producing 120 PSI, I can conclude that it's the one causing the misfire. The next step is to find out what's causing the low compression value. Go to: TEST 2: Wet Compression Test.

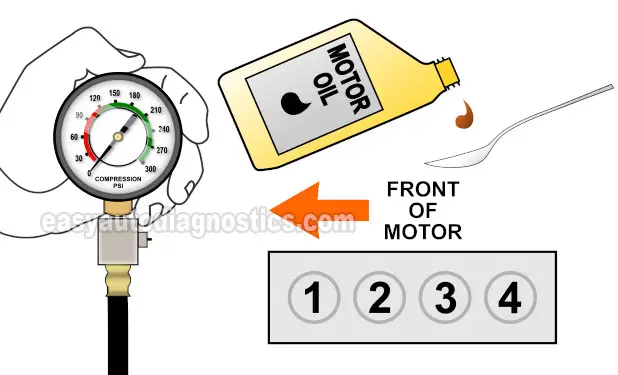

TEST 2: Wet Compression Test

A 'wet' compression test will help you to further nail down the reason for the low cylinder pressure or pressures you recorded in the 'dry' compression test.

To be a bit more specific, a 'wet' compression test will help you find out if the low compression readings are caused by worn piston rings or worn cylinder head valves.

To do a 'wet' compression test, you'll need to add a small amount of engine oil (about 1-2 teaspoons) to the cylinder that had low compression and recheck its compression with the compression tester.

Depending on whether the compression pressure rises (on your compression tester) or not, you'll be able to say that the problem lies in the piston's rings or in the cylinder head valves.

OK, this is what you need to do:

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the 'dry' compression test.

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder.

NOTE: Don't use any type of tool to tightened the compression tester. Hand tight is fine. - 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before),

2.) The compression value will stay the same.

Let's examine your compression test results:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn out and thus the problem is in the bottom end.

CASE 2: The compression value stayed the same. This confirms that the problem is in the cylinder head valves.

If this info saved the day, buy me a beer!