This tutorial will help you to troubleshoot and diagnose a 'no-spark no-start' problem, or a misfire condition on your Chrysler, Dodge, or Plymouth car or mini-van equipped with a 3.0L V6 engine.

In case you're wondering, you don't need a scan tool to take advantage of the step by step diagnostic instructions in this tutorial.

You'll be able to pinpoint the problem to the ignition coil or the crankshaft position sensor (located within the distributor) or the spark plug wires or the distributor cap.

Contents of this tutorial:

- How Does This Type Of Ignition System Work?

- What Tools Do I Need?

- CKP Sensor: Circuit Descriptions

- Ignition Coil: Circuit Descriptions.

- TEST 1: Testing All Spark Plug Wires For Spark.

- TEST 2: Testing For Spark Directly On The Distributor Cap.

- TEST 3: Ignition Coil High Tension Wire Spark Test.

- TEST 4: Testing For Spark Directly On The Ignition Coil's Tower.

- TEST 5: Making Sure The Ignition Coil Is Getting 12 Volts.

- TEST 6: Making Sure The Ignition Coil Is Getting An Activation Signal.

- TEST 7: Making Sure The CKP Sensor Is Getting Power.

- TEST 8: Making Sure The CKP Sensor Is Getting Ground.

- TEST 9: Testing The CKP Sensor Signal.

- TEST 10: Testing The CMP Sensor Signal.

- TEST 11: Other Misfire Causes.

![]() You can find this tutorial in Spanish here: Cómo Probar El Sistema De Encendido (3.0L Chrysler, Dodge, Plymouth) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sistema De Encendido (3.0L Chrysler, Dodge, Plymouth) (at: autotecnico-online.com).

NOTE: You can find the ignition system tests for the 1996-2000 3.0L V6 Caravan, Grand Caravan, Voyager, and Grand Voyager here:

- How To Test The Ignition System (1996-2000 3.0L Caravan, Grand Caravan, Voyager, Grand Voyager) (at: troubleshootmyvehicle.com).

How Does This Type Of Ignition System Work?

Here's a little background information that will help you diagnose the ignition system on your Chrysler, Dodge, or Plymouth vehicle. In a nutshell, when the system is working properly and you turn the key to crank and start your Chrysler (or Dodge or Plymouth) car or mini-van:

- The distributor shaft starts to rotate which causes the crankshaft position sensor to start generating a crankshaft and camshaft position signal, which are sent directly to the fuel injection computer (Henceforth known as the PCM).

- With these two signals, the PCM activates the Auto Shutdown (ASD) Relay to feed power to pretty much every electronic component under the hood, especially the ignition coil.

- Without these two signals, the PCM will not activate the ASD Relay.

- Also, with the signals from the crankshaft (and camshaft) position sensor assembly, the PCM starts to activate the ignition coil to start sparking away. It does this by switching the primary current, flowing across the ignition coil, ON and OFF. This ON/OFF action will henceforth be called the switching (activation) signal.

The CKP sensor is at the heart of this type ignition system. here are some useful facts that you should be aware of about the CKP sensor on your Chrysler (or Dodge or Plymouth) vehicle:

- The crankshaft position sensor assembly is located in the distributor.

- It's an optical type sensor.

- It produces a crankshaft position signal and a camshaft position signal.

- Both signals produce a digital square wave, if tested on an oscilloscope.

- Both of these signals can also be tested with an inexpensive LED light (which is the method I'll use in this article).

- If it goes bad, your car or mini-van will crank but not start.

What Tools Do I Need?

No expensive tools are required to test this type of ignition system. Now, having said that, there some very specific tools that I recommend to use for the tests. So, here's the basic list:

- A Spark tester

- Not just any type of spark tester. I strongly suggest you buy the HEI spark tester (don't have an HEI Spark Tester? Need to buy one? You can buy it here: OTC 6589 Electronic Ignition Spark Tester).

- Don't use a regular spark plug instead of a dedicated spark tester.

- Don't pull the spark plug wire off of the spark plug as the engine is cranking or running. This will give a false result and/or damage the ignition coil.

- An LED light.

- Click here to see what this looks like: The LED Light Test Tool And How To Make One

- Test light.

- Multimeter.

- A cheapie one will do (don't have a digital multimeter? Need to buy one? Click here to see my recommendations: Buying A Digital Multimeter For Automotive Diagnostic Testing).

- Repair manual.

- For whatever other information this article does not cover.

- Helper.

- To help you crank the engine while you observe the LED light (or test light or multimeter).

By the way, you don't need an automotive scan tool for any of these tests.

CKP Sensor: Circuit Descriptions

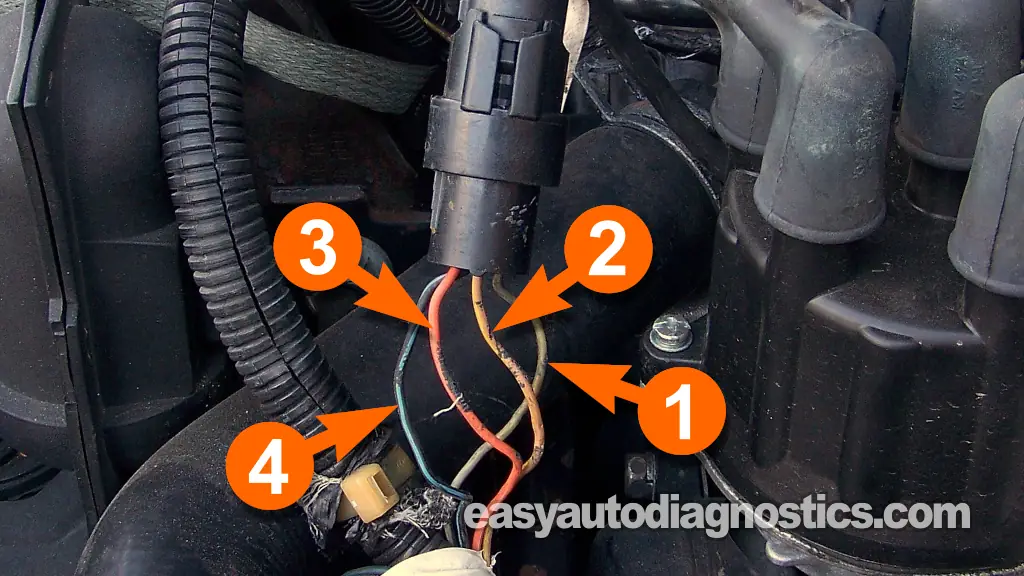

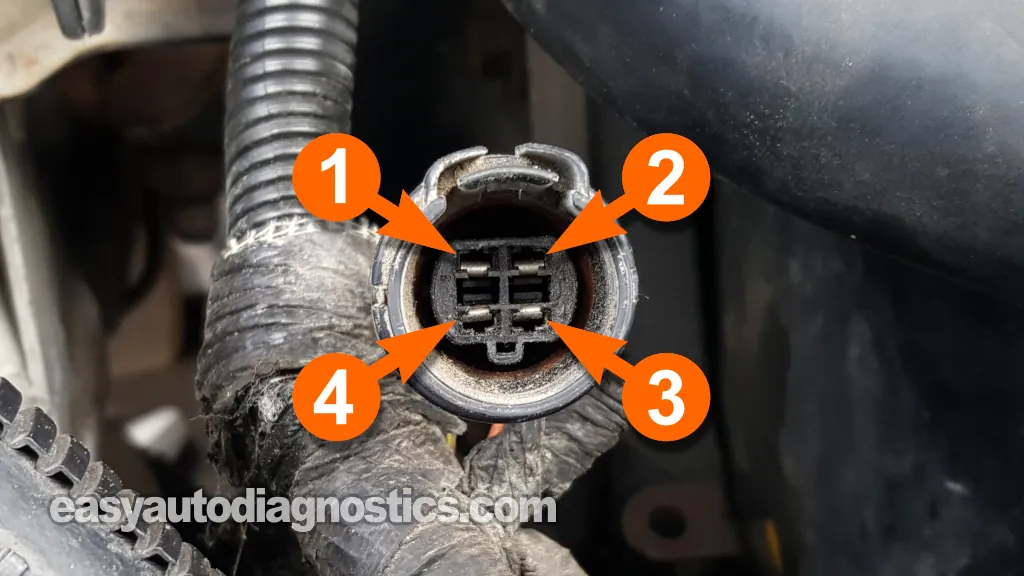

The crankshaft position sensor is a four-wire sensor and it is made up of two sensors in one assembly. It's located inside the distributor. Below are the circuit descriptions that I'll be using across this article.

| Wire | Color | Description |

|---|---|---|

| 1 | Black with gray stripe (BLK/GRY) | CKP Sensor Signal |

| 2 | Tan with yellow stripe (TAN/YEL) | MAP signal |

| 3 | Orange (ORG) | 8 Volts |

| 4 | Black with light blue stripe (BLK/LT BLU) | Sensor Ground |

IMPORTANT: It will be necessary to test some of these circuits while the engine is being cranked. Be careful, use common sense and take all necessary safety precautions.

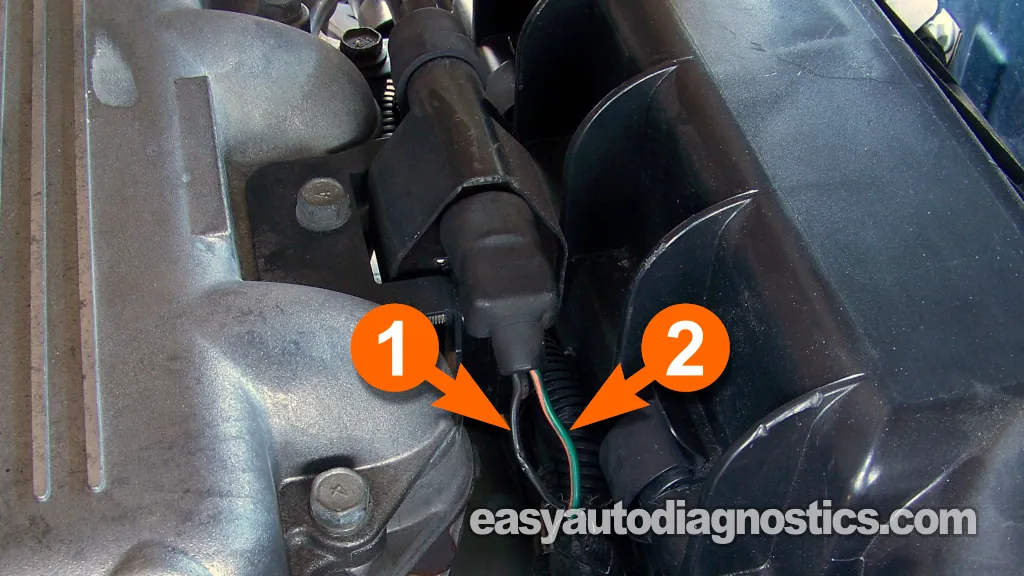

Ignition Coil: Circuit Descriptions

The ignition coil has just two wires coming out of its connector. One feeds it with power (10 to 12 Volts) and the other feeds it the activation (switching) signal. Below are the circuit descriptions that I'll be using in this tutorial.

| Wire | Color | Description |

|---|---|---|

| 1 | Black with grey stripe (BLK/GRY) | Ignition Coil Control Signal |

| 2 | Dark green with orange stripe (DK GRN/ORG) | 12 Volts |

NOTE: Power (12 Volts) is only supplied to the ignition coil when the engine is cranking or running.

IMPORTANT: It will be necessary to test some of these circuits while the engine is being cranked. Be careful, use common sense and take all necessary safety precautions.

TEST 1: Testing All Spark Plug Wires For Spark

The spark test is the starting point for all of the tests in this tutorial and is one of the most important. Here are a couple of important things to keep in mind:

- Use a spark plug wire puller to disconnect the spark plug wires from their spark plugs.

- Don't use a regular spark plug in place of a spark tester for the spark test

- Don't pull the spark plug wire off of the spark plug either while the engine is cranking (to check for spark).

Whether the engine in your car or mini-van does not start or starts but runs with a misfire, I recommend that you test all spark plug wires for spark to get the most accurate test result.

OK, let's start:

- 1

Remove the spark plug wire from its spark plug.

- 2

Attach the HEI spark tester to the spark plug wire.

If you don't have an HEI Spark Tester and need to buy one, you can buy it here: OTC 6589 Electronic Ignition Spark Tester. - 3

Connect the spark tester to the battery negative (-) post with a battery jump start cable.

You can also connect the spark tester to a clean and unpainted metal surface on the engine. - 4

Have your helper crank the engine while you observe the spark tester.

CAUTION: The engine may or may not start, either way be careful. - 5

Repeat the test on all of the remaining spark plug wires.

Let's examine your test result:

CASE 1: You got spark on all of the spark plug wires. This is the correct and expected test result.

With this result, you can conclude that the spark plug wires, distributor cap and rotor, crankshaft position sensor (within the distributor), and ignition coil are working.

If the engine isn't starting, it's not because one of these components has failed. For more suggestions as to what could be causing the misfire on your Chrysler car or mini-van, go to: TEST 11: Other Misfire Causes.

CASE 2: You got NO spark on none of the spark plug wires. This result doesn't condemn any specific component just yet.

The next step is to check that the distributor cap is getting spark from the ignition coil. For this test, go to: Test 3: Ignition Coil High Tension Wire Spark Test.

CASE 3: You got spark on some but not all of the spark plug wires. More than likely the spark plug wires are bad or the distributor cap is bad.

It's a common problem for one or two spark plug wires to go bad or for one or two distributor cap towers to go bad and not let spark thru'. 90% of the time replacing the distributor cap, the distributor rotor and the spark plug wires should solve your problem, BUT to further test this, go to: Test 2: Testing For Spark Directly On The Distributor Cap.