TEST 8: Making Sure The CKP Sensor Is Getting Ground

Besides power (6 to 8 Volts DC), the CKP and CMP sensor assembly on your distributor needs Ground.

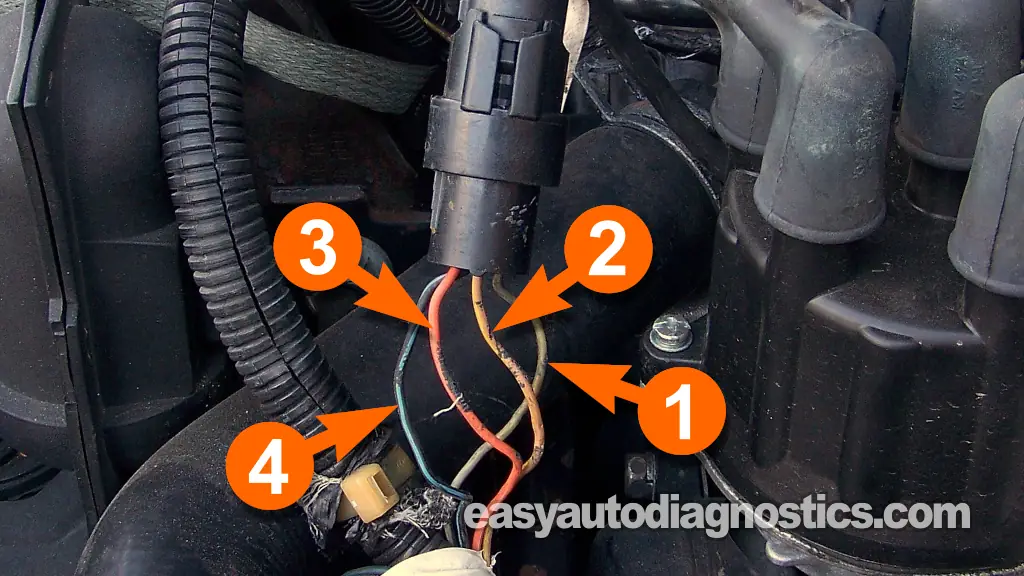

This Ground is provided internally by the fuel injection computer and the wire that delivers it to the CKP sensor assembly is the black with light blue stripe (BLK/LT BLU) wire of the distributor's 4-wire connector.

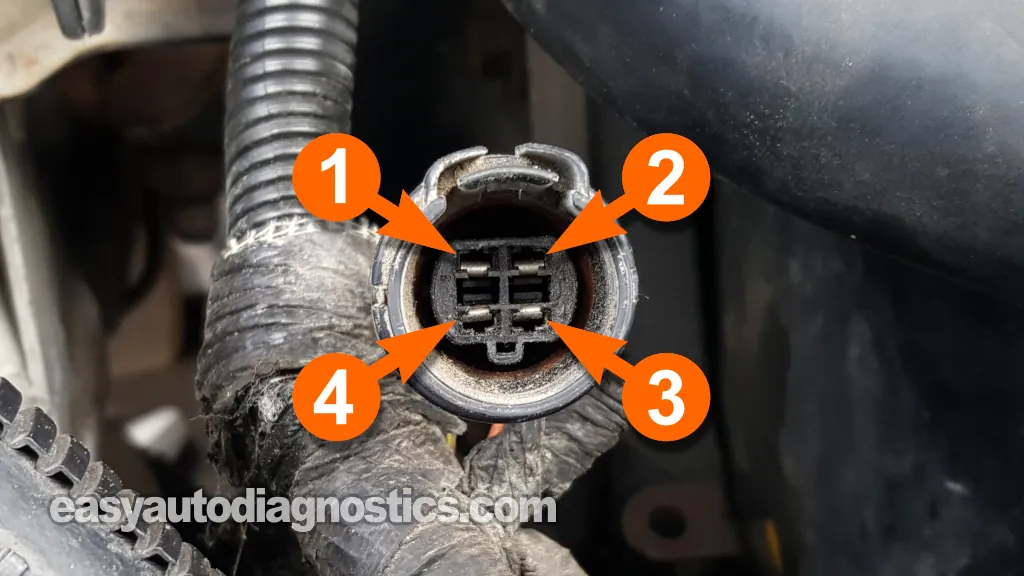

The BLK/LT BLU wire connects to the female terminal labeled with the number 4 in image 1 of 2 in the image viewer above.

IMPORTANT: Be careful not to short this wire to battery voltage, or the fuel injection computer will get damaged. Also, for the most accurate test result, don't use a test light to verify this voltage, use a multimeter.

OK, the test goes like this:

- 1

Place the multimeter in Volts DC mode.

- 2

Disconnect the distributor 4-wire connector.

- 3

Connect the red multimeter test lead directly to the battery's positive (+) terminal.

- 4

Have your assistant turn the key to the ON position but not crank or start the engine.

- 5

Gently probe the terminal labeled with the number 4 with the black multimeter test lead.

Terminal 4 should connect to the black with light blue stripe wire.

IMPORTANT: This test is done on the engine wiring harness connector and not the connector that belongs to the distributor itself. - 6

The multimeter should register between 10 to 12 Volts DC.

Let's interpret your test results:

CASE 1: The multimeter displayed 10 to 12 Volts DC. This test result tells you the crank sensor is being supplied with a good Ground by the PCM.

The next test is to verify that the CKP sensor part of the CKP/CMP sensor assembly is producing a good signal, go to: TEST 9: Testing The CKP Sensor Signal.

CASE 2: The multimeter DID NOT display 10 to 12 Volts DC. Recheck all your connections and retest. If still the multimeter does not display the indicated voltage, you'll need to find out why the PCM or the circuit is not providing this Ground path. Without this sensor Ground, the CKP and CMP sensor assembly will not work. Resolving the cause of this missing Ground will solve the no-spark no-start issue with your Chrysler car or mini-van.

TEST 9: Testing The CKP Sensor Signal

As mentioned earlier, the crankshaft position sensor assembly, on your Chrysler (Dodge or Plymouth) vehicle equipped with a 3.0L V6, is two sensors in one. One part is the crankshaft position sensor and the other is the camshaft position sensor.

In this test step, we'll verify that the CKP sensor part is producing a good signal that the fuel injection computer can use to get the ignition system to spark away and the fuel injectors to inject fuel.

This test is done with an LED light and by turning the engine by hand (using a 1/2 inch ratchet on the crankshaft pulley).

The wire that we're going to tap into is the grey with black stripe (GRY/BLK) wire of the distributor's 4-wire connector.

IMPORTANT: Proceed with this test only if you have gotten a no spark result from all of the spark plug wires (TEST 1) and no spark from the ignition coil tower (TEST 4).

NOTE: You can see an example of the LED light and where to buy it here: The LED Light Test Tool And How To Make One.

IMPORTANT: This test is done with the distributor connected to its engine wiring harness connector. To connect the LED light to the CKP signal wire, you'll need to pierce the wire with an appropriate tool and then connect the indicated LED wire to this tool.

Let's get testing:

- 1

Disconnect the ignition coil's electrical connector.

IMPORTANT: This is an important safety precaution. Do not proceed with this test without disconnecting this connector. - 2

Connect the red wire of the LED to the battery positive (+) terminal.

- 3

Connect the black wire of the LED to the wire identified with the number 4 in the photo.

The gray with black stripe wire should connect to terminal 4 of the distributor's engine wiring harness connector (which has female terminals).

IMPORTANT: This test is done with the distributor connected to its engine wiring harness connector. - 4

The LED will come ON and stay ON. This is normal.

- 5

With an appropriate tool (like a 1/2 inch ratchet and a socket), manually turn the crankshaft pulley slowly.

IMPORTANT: Do not crank the car with the starter motor. - 6

The LED light should flash ON and OFF the whole time that you're slowly turning the crankshaft pulley by hand.

Let's analyze your test results:

CASE 1: The LED light flashed ON and OFF the whole time the engine was being manually cranked. This test result indicates the crankshaft position sensor part of the CKP/CMP sensor assembly is creating and sending its signal.

The next test is to test the camshaft position sensor part of the CKP sensor, go to: TEST 10: Testing The CMP Sensor Signal.

CASE 2: The LED light DID NOT flash ON and OFF the whole time the engine was being manually cranked. This test result indicates the crankshaft position sensor is bad and is the cause of the no-spark no-start condition. Replace the crankshaft position sensor in the distributor.

TEST 10: Testing The CMP Sensor Signal

This test step will verify that the CMP sensor part (of the crankshaft position sensor) is producing a good signal that the PCM can use to start ignition spark and fuel injection.

This test is also done with an LED light and by cranking the engine by hand (no starter motor).

The wire that we're gonna tap into is the tan with yellow stripe (TAN/YEL) wire of the distributor's 4-wire connector.

IMPORTANT: Proceed with this test only if you have gotten a no spark result from all of the spark plug wires (TEST 1) and no spark from the ignition coil tower (TEST 4).

NOTE: You can see an example of the LED light and where to buy it here: The LED Light Test Tool And How To Make One.

IMPORTANT: This test is done with the distributor connected to its engine wiring harness connector. To connect the LED light to the CKP signal wire, you'll need to pierce the wire with an appropriate tool and then connect the indicated LED wire to this tool.

OK, let's get testing:

- 1

Disconnect the ignition coil's electrical connector.

IMPORTANT: This is an important safety precaution. Do not proceed with this test without disconnecting this connector. - 2

Connect the red wire of the LED to the battery positive (+) terminal.

- 3

Connect the black wire of the LED to the wire identified with the number 2 in the photo.

The tan with yellow stripe wire should connect to terminal 2 of the distributor's engine wiring harness connector (which has female terminals).

IMPORTANT: This test is done with the distributor connected to its engine wiring harness connector. - 4

The LED will come ON and stay ON. This is normal.

- 5

With an appropriate tool (like a 1/2 inch ratchet and a socket), manually turn the crankshaft pulley slowly.

IMPORTANT: Do not crank the car with the starter motor. - 6

The LED light should flash ON and OFF the whole time that you're slowly turning the crankshaft pulley by hand.

OK, let's see what your LED light test results mean:

CASE 1: The LED light flashed ON and OFF the whole time the engine was being manually cranked. This test result tells you the camshaft position sensor part of the CKP/CMP sensor assembly is creating and sending its signal.

The cause of your no-start condition does not lie in the ignition system.

CASE 2: The LED light DID NOT flash ON and OFF the whole time the engine was being manually cranked. This test result tells you the camshaft position sensor is bad and is the cause of the no-spark no-start condition. Replace the crankshaft position sensor in the distributor.