Testing the manifold absolute pressure (MAP) sensor, on the 1992-1996 3.9L Dodge Dakota is not hard at all.

In this tutorial, I'm gonna' show you how to test it using a vacuum pump and a multimeter. With your test results you'll be able to find out if it's bad or not.

Contents of this tutorial at a glance:

![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1992-1996 3.9L V6 Dodge Dakota) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP (1992-1996 3.9L V6 Dodge Dakota) (at: autotecnico-online.com).

NOTE: This tutorial applies to the following vehicles since they use the exact same MAP sensor: 1992, 1993, 1994, 1995, 1996 3.9L V6 Dodge Dakota.

WIRING DIAGRAM: You can find the fuel injection system wiring diagram here: Engine Management Sensor Circuit Diagram (1994-1995 3.9L V6 Dodge Dakota).

Symptoms Of A Bad MAP Sensor

The MAP sensor is a critical component of the engine management system of your 3.9L V6 Dodge Dakota.

To be a bit more specific, the MAP sensor is one of three important components that the fuel injection computer uses to calculate the amount of air entering the engine. Once it calculates the amount of air the engine is breathing it then is able to calculate the amount of fuel to inject into the cylinders.

So when the MAP sensor fails on your 3.9L V6 Dodge Dakota, engine performance is going to suffer big time.

You're going to see a MAP sensor diagnostic trouble code lighting up the check engine light:

- Code 13 No Change In MAP From Start To Run.

- Code 14 MAP Sensor Voltage Too Low.

- Code 15 MAP Sensor Voltage Too High.

You're also going to see one or more of the following symptoms:

- Rough idle.

- 'Rotten egg' smell coming from the exhaust.

- Won't pass the state mandated emissions test.

- Bad gas mileage.

- Lack of power, rough idle, or hesitation.

- Engine cranks a long time before starting.

MAP Sensor Circuit Descriptions

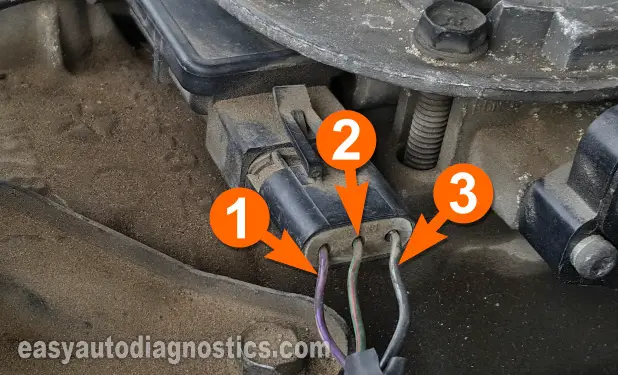

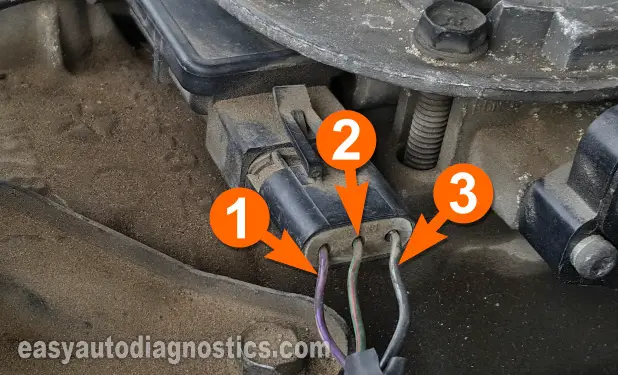

The MAP sensor is a 3 wire type sensor. This means that it has a power wire, a Ground wire and a signal wire. The table below has a brief description of each:

| Terminal | Wire | Description |

|---|---|---|

| 1 | VIO/WHT | 5 Volts |

| 2 | DK GRN/RED | MAP Signal |

| 3 | BLK/LT BLU | Ground |

Where To Buy The MAP Sensor And Save

The 1992-1996 3.9L V6 Dodge Dakota's MAP sensor can cost a pretty penny. The following links will help you to comparison shop and hopefully save you a few bucks on its purchase:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

NOTE: The above manifold absolute pressure (MAP) sensor fits the following vehicles: 1992, 1993, 1994, 1995, 1996 3.9L V6 Dodge Dakota.

TEST 1: Testing The MAP Sensor Voltage Signal

The very first thing that we're going to do is make sure that the MAP sensor is producing a MAP signal that decreases as vacuum is applied to it.

In a MAP sensor that's functioning correctly, the more vacuum is applied to the MAP sensor the smaller the voltage value it produces.

When a MAP sensor fails, it's simply going to stay stuck producing one voltage value no matter how much vacuum is applied to it.

So for our first test, we're going to remove the MAP sensor from its location on the throttle body and connect a multimeter to the dark green with red stripe (DK GRN/RED) wire of the MAP sensor's connector.

Then we'll manually apply vacuum to it and see if the MAP voltage signal decreases as we apply vacuum to the MAP sensor.

NOTE: If you don't have a vacuum pump you can use your mouth to apply vacuum to the MAP sensor. If you would like to buy a vacuum pump, check out this link: HTOMT 2 in 1 Brake Bleeder Kit Hand held Vacuum Pump Test Set for Automotive with Sponge Protected Case,Adapters,One-Man Brake and Clutch Bleeding System.

IMPORTANT: The manifold absolute pressure (MAP) sensor must remain connected to its electrical connector for this test to function properly. To be able to access the voltage inside the signal wire, you'll need to use either a back probe or a wire piercing probe. You can see an example of this tool here: Wire Piercing Probe.

Let's get started:

- 1

Remove the MAP sensor from the throttle body.

- 2

Connect your vacuum pump to the MAP sensor's vacuum inlet port.

NOTE: Reconnect the MAP sensor to its connector if you disconnected it. - 3

Place your multimeter in Volts DC mode.

- 4

Connect the red multimeter test lead to the DK GRN/RED wire of the MAP sensor's connector.

This wire is identified by the number 1 in the photo above.

Remember, the MAP sensor must remain connected to its 3 wire connector. - 5

Ground the black multimeter test lead directly on the battery negative (-) terminal.

- 6

Turn the key the ON position but don't start the engine. This will power up the MAP sensor and you should see a reading of 4.7 Volts DC on your multimeter.

- 7

Now, apply vacuum to the MAP sensor with the vacuum pump (or your mouth). The voltage signal value should decrease.

If you're using a vacuum pump: At 5 in.Hg → 3.9 Volts. At 10 in.Hg → 3 Volts. At 15 in.Hg → 2.1 Volts. At 20 in.Hg → 1.2 Volts. - 8

Release the vacuum. Once released, your multimeter should show the original voltage value.

Repeat this test step several times making sure that each time the voltage decreases/increases as you apply/release vacuum.

Let's examine your test:

CASE 1: The MAP voltage signal decreased and increased as you applied and released vacuum. This is the correct test result and lets you know that the MAP sensor is working correctly (not defective).

You can also conclude that the MAP sensor is getting 5 Volts and Ground.

CASE 2: The MAP voltage signal DID NOT decrease/increase as you applied and released vacuum. This test result usually indicates that the MAP sensor is defective.

To make sure the MAP sensor is truly defective we have to make sure that it's getting 5 Volts. For this test go to: TEST 2: Making Sure The MAP Sensor Has 5 Volts.

CASE 3: The multimeter DID NOT register any voltage. This test result usually indicates that the MAP sensor is defective.

To make sure the MAP sensor is truly defective we have to make sure that it's getting 5 Volts. For this test go to: TEST 2: Making Sure The MAP Sensor Has 5 Volts.