TEST 2: Making Sure The MAF Sensor Is Getting Chassis Ground

Now that you have confirmed that the RED wire is providing 12 Volts to the MAF sensor, the next step is to verify that the black with white stripe (BLK/WHT) wire is providing chassis Ground.

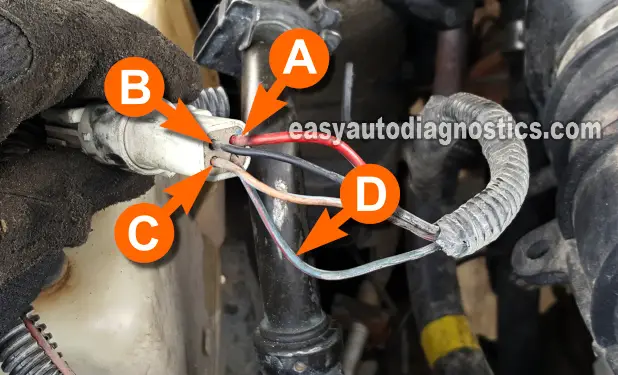

The BLK/WHT wire is labeled with the letter B in the photo above.

As in the previous test, we'll do a simple voltage test with the multimeter to verify the presence of Ground on the BLK/WHT wire.

Let's get going:

- 1

Disconnect the MAF sensor from its electrical connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Connect the black multimeter test lead to the BLK/WHT wire of the MAF sensor connector.

The BLK/WHT wire is labeled with the letter B in the photo above. - 4

Connect the red multimeter test lead probe the battery positive (+) terminal.

- 5

You should see 10 to 12 Volts on the multimeter.

NOTE: No need to turn the key to the ON position since this is a chassis Ground and is available at all times.

Let's see what your test results mean:

CASE 1: Your multimeter registered 10 to 12 Volts. This is the correct result and confirms chassis Ground is available to the MAF sensor.

The next step is to make sure the MAF sensor is getting Ground from the fuel injection computer. Go to: TEST 3: Making Sure The MAF Sensor Is Getting Ground (PCM).

CASE 2: Your multimeter DID NOT register 10 to 12 Volts. This test result indicates the MAF sensor is not receiving chassis Ground.

Recheck all your multimeter connections and test again. If your multimeter still doesn't read 10 to 12 Volts, you can conclude that the MAF sensor itself isn't faulty as it won't work without the BLK/WHT wire providing chassis Ground.

Your next step is to figure out why this chassis Ground is missing and restore it.

TEST 3: Making Sure The MAF Sensor Is Getting Ground (PCM)

The MAF sensor also receives Ground from the fuel injection computer.

The wire that provides this Ground is the tan with light blue stripe (TAN/LT BLU) wire of the MAF sensor 4-wire connector.

With a simple multimeter voltage test, we can easily verify that this Ground is present in the TAN/LT BLU wire.

CAUTION: Be careful when testing this circuit! Do not connect this wire directly to 12 Volts. Otherwise you'll damage the fuel injection computer. The multimeter test suggested below is a safe way to test for the presence of Ground in the wire.

These are the test steps:

- 1

Disconnect the MAF sensor from its electrical connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Connect the black multimeter test lead to the TAN/LT BLU wire of the MAF sensor connector.

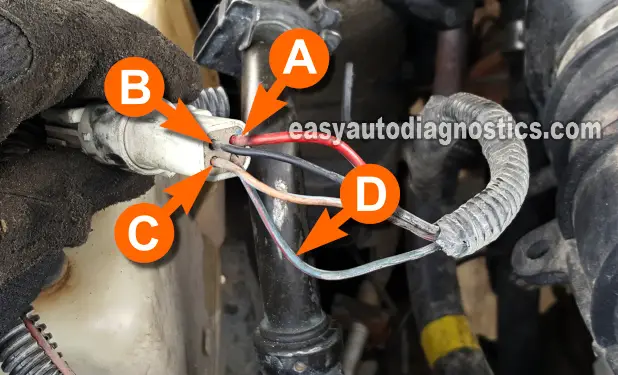

The TAN/LT BLU wire is labeled with the letter C in the photo above. - 4

Connect the red multimeter test lead probe the battery positive (+) terminal.

- 5

Turn the key to the ON position but don't crank or start the engine.

- 6

You should see 10 to 12 Volts on the multimeter.

Let's see what your test results mean:

CASE 1: Your multimeter read 10 to 12 volts. This is the correct result and confirms that the fuel injection computer is providing Ground.

The next step is to check the MAF sensor signal with the engine running, for this, go to: TEST 4: Testing The MAF Signal.

CASE 2: Your multimeter DID NOT read 10 to 12 Volts. This test result indicates the MAF sensor is not receiving Ground from the fuel injection computer.

Recheck all your multimeter connections and test again. If your multimeter still doesn't read 10 to 12 Volts, you can conclude that the MAF sensor itself isn't faulty as it won't work without the TAN/LT BLU wire providing Ground from the fuel injection computer.

Your next step is to figure out why this Ground (from the fuel injection computer) is missing and restore it.

TEST 4: Testing The MAF Signal

In order to successfully diagnose the mass air flow sensor, it's important to know the following:

- The MAF sensor signal voltage increases as engine speed increases.

- Once engine speed decreases, the MAF sensor signal voltage also decreases.

What's really cool is that we can observe these changes in the signal voltage with a multimeter.

In this final test section of the tutorial, we'll connect our multimeter to the MAF sensor signal wire and test the performance of the signal voltage.

If the MAF sensor is working properly, its signal voltage should increase/decrease as we increase/decrease the engine speed.

Generally, when the MAF sensor fails, it will generate a voltage signal that will stay stuck in one value regardless of engine speed.

NOTE: It is important that the engine is at normal operating temperature. So start the engine and let it warm up to normal operating temperature.

IMPORTANT: The MAF sensor must be connected to its connector to perform this test. You'll need to use a back probe on the connector or a wire piercing probe on the wire. You can see an example of this tool here: Wire Piercing Probe Review (Power Probe PWPPPPP01).

- 1

Reconnect the MAF sensor to its electrical connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Connect the red multimeter test lead to the LT BLU/RED wire using a suitable tool.

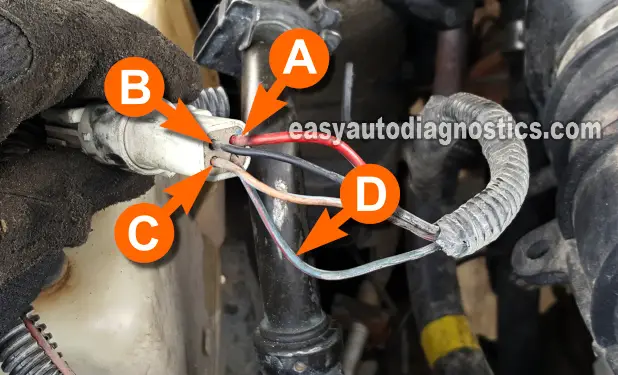

The LT BLU/RED wire is labeled with the letter D in the photo above. - 4

Connect the black multimeter test lead to the battery (-) negative terminal.

- 5

Crank and start the engine and let her idle.

Once the idle stabilizes, take a look at the voltage number or numbers your multimeter is throwing at you. This voltage may fluctuate a little or a lot, and this is OK. Whatever they're doing, this is your base MAF signal voltage. - 6

Open the throttle (manually) to increase engine speed.

- 7

The voltage value should increase as the engine speed increases.

- 8

Release the throttle to decrease engine speed.

- 9

The voltage value should decrease as the engine speed decreases.

- 10

Repeat steps 6 through 9 several times to make sure of your test result.

Let's see what your test results mean:

CASE 1: The voltage reading increased/decreased as you increased/decreased the engine speed. This tells you that the MAF sensor is good and is not the cause of the engine performance problem.

CASE 2: The voltage value did not change as you increased/decreased the engine speed. Double check all your multimeter connections and test again.

If you still don't see the displayed voltage rising and falling, you can conclude that the mass air flow (MAF) sensor is faulty if you have:

- Confirmed the MAF sensor is receiving power (TEST 1).

- Confirmed the MAF sensor is receiving chassis Ground (TEST 2).

- Confirmed the MAF sensor is receiving Ground from the PCM (TEST 3).

- Confirmed the MAF voltage signal does not increase/decrease as engine speed increases/decreases (this test section).

More 2.3L Ford Ranger Tutorials

A full list of tutorials can be found here:

Here's a sample of the tutorials you'll find:

- How To Test The Throttle Position Sensor (2.3L Ranger, Mustang, B2300).

- How To Test The Ignition Module And Crank Sensor (2.3L Ranger, Mustang, B2300).

- How To Test For A Blown Head Gasket (2.3L Ranger, Mustang, B2300).

- Testing The Blower Resistor (1995-1997 2.3L Ford Ranger).

If this info saved the day, buy me a beer!